Nouvelles de l'industrie

Gantry cranes are a type of bridge crane, characterized by a horizontal main beam supported by two legs, forming a gantry shape, and running on ground rails. They are primarily used in outdoor locations such as open-air freight yards, ports, and construction sites for cargo handling and component lifting. This article will provide a detailed introduction to the definition, structural components, functional characteristics, and types of gantry cranes. If you are unsure how to choose the right gantry crane, this article will help you make an informed decision. Please continue reading:

Gantry cranes use a gantry frame structure, which includes a horizontal main beam, vertical supporting legs on both sides, and other components such as the lifting mechanism. They feature high site utilization, a large working range, wide adaptability, and strong versatility, and people primarily use them for loading and unloading goods and bulk materials in outdoor yards and storage areas.

The main characteristics of gantry cranes are their large span, stable structure, and high efficiency. They are capable of multi-directional movement, including horizontal, vertical, and lateral movements, making them very flexible. In practical applications, gantry cranes are often used for lifting heavy objects, such as containers and large equipment. In ports, logistics centers, and shipyards, gantry cranes effectively handle the transportation, loading, unloading, and stacking of materials.

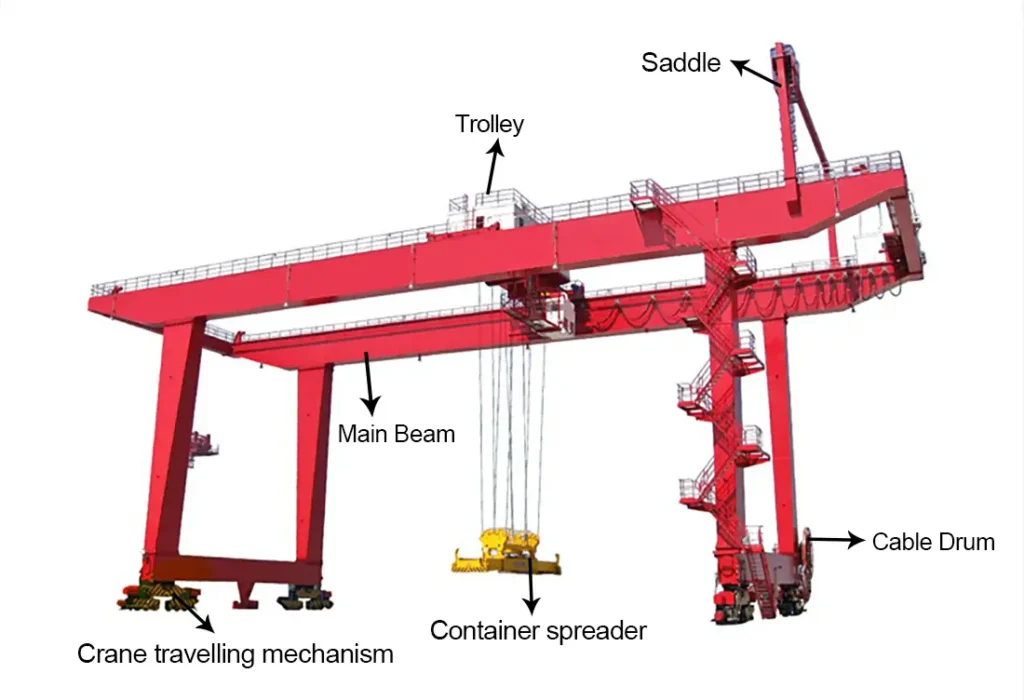

A gantry crane consists of components such as the main beam, support legs, trolley running mechanism, hoisting mechanism, driver's cab, ladder and platform, and buffers. The functions and characteristics of each component are as follows:

Weihua Group, as a professional manufacturer and customizer of gantry cranes, offers a variety of different types of gantry cranes. The following is a list of some of them:

A small portable gantry crane is a mobile lifting device. It does not require a fixed foundation, allowing for quick installation and disassembly. It is suitable for temporary lifting operations, workshop handling, outdoor work, and various other scenarios.

Features: Lightweight and portable, easy installation, cost-effective

Application scenarios: Factories, workshops, logistics and warehousing

A semi-gantry crane consists of one or two main beams, an electric trolley, and a supporting leg on one side. This type of gantry crane makes full use of the available space and is suitable for applications where cost-effectiveness and site adaptability are important.

Features: Low maintenance costs, high positioning accuracy, high space utilization

Application scenarios: Small and medium-sized industrial manufacturing, logistics and warehousing, light industry, etc.

Features a single girder structure and uses an electric hoist as the lifting system, running along a track. It is suitable for both indoor and outdoor environments and can lift various types of materials.

Features: Simple structure, robust and durable, long service life

Applications: Steel mills, automobile manufacturing, construction sites

Utilizes a truss structure as its metal frame, making it lightweight, strong, and wind-resistant. It boasts excellent load-bearing capacity and stability. Suitable for frequent operation in outdoor environments.

Features: High wind resistance, strong load-bearing capacity, smooth operation

Application scenarios: Bridge construction, manufacturing, power and energy

Adopting European design standards and advanced manufacturing processes, it features a lightweight structure, modular design for easy maintenance, low energy consumption, and low noise, ideal for efficient material handling operations.

Features: Lightweight, low headroom design, intelligent control

Application scenarios: Heavy industrial manufacturing, energy and chemical industries

A specialized lifting equipment specifically designed for container yard stacking operations. It features a mobile rubber-tired structure, allowing for free movement without the need for rail foundations, and is capable of handling heavy objects such as containers and steel structures with high precision and efficiency.

Features: Flexible movement, multiple power options, efficient stacking

Application Scenarios: Container ports, railway freight hubs, logistics parks

Utilizes multiple sets of steel wheels to run on rails and is electrically driven. It features a double-girder structure and a dedicated container spreader for efficient and automated operation.

Features: Precise positioning, high load capacity, automation and intelligence

Application scenarios: Railway freight yards, warehousing and distribution centers, port transfer stations

| Types | Capacity | La portée | Application | Price Range |

|---|---|---|---|---|

| Smal portable gantry crane | 0.5-10tons | 2-12M | Suitable for garages and workshops, often used for lifting and moving light materials. | $1300 ~ $13000,depending on specifications |

| Semi gantry crane | 10-100tons | 7.5-25.5M | Applicable to mine ports, railway freight stations, open-air warehouses. | $12000 ~ $177000,depending on specifications |

| Portique de levage à une poutre MH | 5-30tons | 7.5-30M | Suitable for construction sites, logistics warehousing and other occasions. | $13500 ~ $54700,depending on specifications |

| MH Single Girder Truss Gantry Crane | Suitable for light industrial production, mechanical assembly operations, etc. | $13000 ~ $54000,depending on specifications | ||

| European Double Beam goliath crane | 10-100tons | Usually, it is in steel metallurgy, hydro-power, aerospace, ships, automobiles, coal, petrochemicals, etc. | $22000 ~ $208000,depending on specifications | |

| RTG Rubber Tyred Gantry Crane | 35-70tons | 23/26M | It is mainly used for lifting, moving and stacking containers, and is widely used in ports and large logistics centers, etc. | $950680 ~ $1900875,depending on specifications |

| Rail Mounted Gantry Crane | 30.5-50tons | 26/30/35M | Mainly used in ports, docks and inland container yards. | $494000 ~ $778250,depending on specifications |

Grue portique

Pont roulant

1.Working environments: Bridge cranes mainly operate indoors, handling material lifting in warehouses and workshops; gantry cranes mainly operate outdoors, handling the loading and unloading of goods.

2.Appearances: Bridge cranes lack supporting legs. Instead, concrete columns or brackets within a workshop support their ends, giving them a bridge-like appearance. In contrast, gantry cranes feature two supporting legs installed beneath the main beam, resembling a door frame.

3. Functions: O cranes save space by being suspended overhead in workshops, thus occupying no floor area. Gantry cranes, however, offer high site utilization, a large working range, wide adaptability, and strong versatility. These characteristics lead to their widespread use in construction sites and ports.

4.Running tracks: Bridge cranes are suspended on tracks supported by fixed columns between bays of a building, used in workshops, warehouses, etc.; gantry cranes have two tall supporting legs at both ends of the main beam, running along tracks on the ground.

Gantry overhead crane specifications and key parameters include:

| Modèle | RTG Rubber Tyred Gantry Crane | |||

| Capacité de levage nominale (tonnes) | 35 | 41 | 70 | |

| Distance de la base (mètre) | 7 | 7 | 7.5 | |

| Portée (mètre) | 23.47/26 | 23.47/26 | 23.47/26 | |

| Hauteur de levage (mètre) | 15.5/18.5 | 15.5/18.5 | 15.5/18.5 | |

| Empiler les couches | 4/5 | 4/5 | 4/5 | |

| Spécification du conteneur | 20',40',45' | 20',40',45' | 20',40',45' | |

| Vitesse | Levage (charge complète/charge vide) | 20/40 | 25/50 | 25/50 |

| Déplacement du portique (charge pleine/charge vide) | 30/130 | 30/130 | 30/130 | |

| Voyage en trolley | 70 | 70 | 70 | |

| Numéros de roue | 8 | 8/16 | 16 | |

| Charge maximale de la roue | 300 | 320/180 | 200 | |

| Alimentation électrique | Groupe électrogène diesel ou triphasé AC380V 50Hz | |||

High Efficiency: Features a large lifting capacity and working range, enabling rapid lifting and transportation of various heavy objects, significantly improving loading and unloading efficiency and reducing operating time.

Flexible and Convenient: Can be flexibly moved in different locations, adapting to various operating scenarios. It can be used in ports, freight yards, workshops, and other environments.

Precise Positioning: Utilizing an advanced control system, it achieves precise lifting and positioning, ensuring accurate placement of goods in designated locations and minimizing errors.

Safe and Reliable: Equipped with comprehensive safety protection devices, such as limit switches and brakes, effectively guaranteeing operational safety and reducing the risk of accidents.

Stable Structure: Made of high-quality steel, with a reasonable structural design, it possesses excellent stability and load-bearing capacity, ensuring long-term stable operation.

Wide Applicability: Meets the needs of various industries for heavy object lifting, such as logistics, construction, and manufacturing, providing strong support for cargo handling in various fields. It is an indispensable piece of equipment in modern industrial production and logistics transportation.

Customized gantry mounted cranes are mainly designed according to the specific needs of the user, such as the specific working environment, load requirements, and so on. Key parameters for customization include:

Gantry cranes typically have a lifting capacity of 1 to 100 tons, and can also be customized according to different usage requirements. Their robust structure and design enable them to handle heavy loads, making them ideal for use in ports, open-air warehouses, steel mills, and other manufacturing industries.

Weihua is a renowned manufacturer of gantry cranes. Since its establishment in 1988, its production base has covered 3.42 million square meters, and its products are exported to over 170 countries and regions. We provide one-stop solutions ranging from customized design and installation to technical guidance. Our highly professional and experienced sales team is dedicated to providing customers with detailed product information to help them make informed decisions.

This article aims to help you better understand gantry cranes. Whether you are looking for customized solutions to meet your specific needs or want to learn more about different types of gantry cranes, we hope this article will provide you with valuable information.

We not only manufacture and supply gantry cranes but also provide diverse material handling and lifting solutions tailored to customer needs, including electric transfer carts and lifting platforms. If you have any specific requirements or need further assistance, please feel free to contact our team of experts. We will provide you with customized solutions and professional support.

Date :

Date :

Date :

Soumettre une demande