Ponts roulants

European double girder bridge crane is a kind of overhead crane, adopting European advanced design concept and manufacturing standards, featuring compact structure, light weight, smooth operation, energy saving and high efficiency, etc. It is widely used in medium and heavy material handling in factories, warehouses, power stations, ports, and other places.

The two main beams are of high steel strength with good bending, torsion and shear strength. Due to the box girder structure, the main girder ensures the rationality of the whole equipment and reduces its own weight. The whole bridge crane can be moved longitudinally on the track. The motorized trolley is located between the two main girders. The trolley can be moved back and forth by the hoisting mechanism to raise or lower the goods.

European Double Girder Bridge Crane is mainly composed of the bridge, traveling mechanism, trolley, cab, and electrical equipment. The trolley traveling mechanism is driven by a three-in-one reduction motor, and the frequency conversion system provides smooth acceleration and running speed. European double girder bridge cranes are widely used in warehouses, workshops, and material yards to assist in unloading or carrying heavy objects. Usually, European double girder bridge cranes/EOT cranes can not only achieve two-way movement, but also easily lift and lower heavy objects. When European double girder bridge cranes are used in explosive, flammable, or corrosive environments, special technical means are required to ensure operational safety.

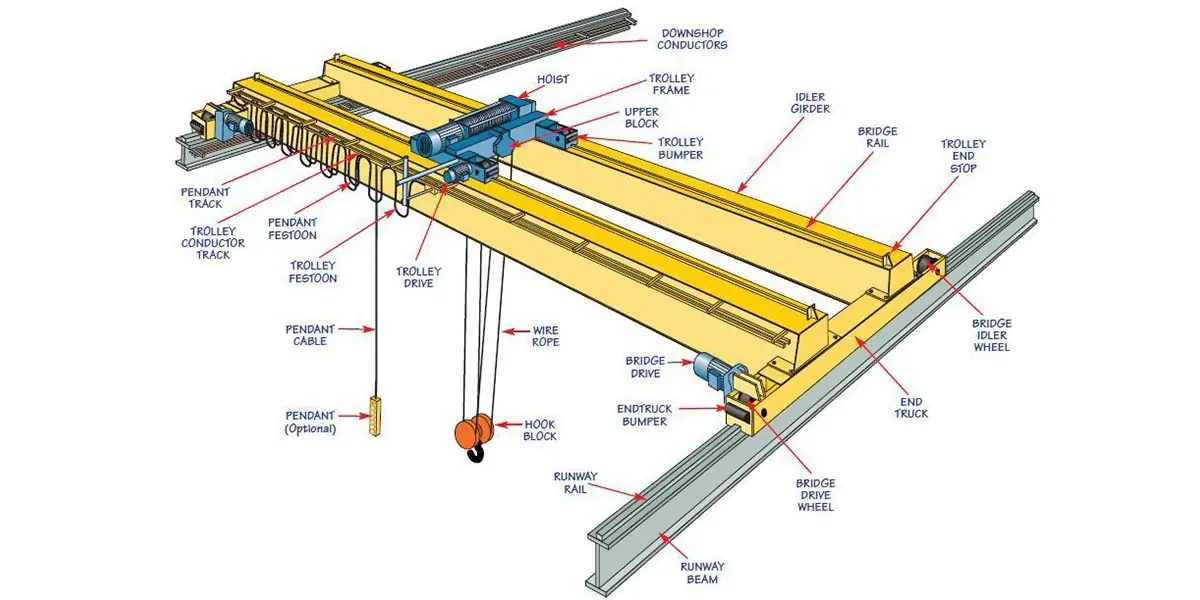

A double girder overhead travelling crane is suitable for heavy lifting operations in general industry, mainly composed of main girder, hoisting mechanism, traversing mechanism, trolley, wheels, conductive device, brake, speed reducer, steel wire rope, hook set, and other components.

Main beam: The main body of the whole overhead crane, used to support and carry the weight of the crane.

Lifting mechanism: The main components responsible for lifting and lowering are the drum, reducer, brake, wire rope, and so on.

Traverse mechanism: Responsible for moving the trolley along the direction of the bridge track, the main components include the reducer, motor, wheels, and so on.

Trolley: Moving on the main beam, carrying the lifting mechanism and hook, etc.

Wheels: Support the trolley to move on the main girder track.

Conductive device: Used to supply power to the crane.

Brake: Responsible for controlling and braking the movement of the crane.

Reducer: Converts the high speed of the motor to the working speed required by the crane.

Wire Rope: Used for lifting and transferring goods.

Hook Set: Used for gripping and lifting the load.

Other Components: Such as couplings, buffers, travel switches, etc.

| Nom du produit | QDXX type Pont roulant |

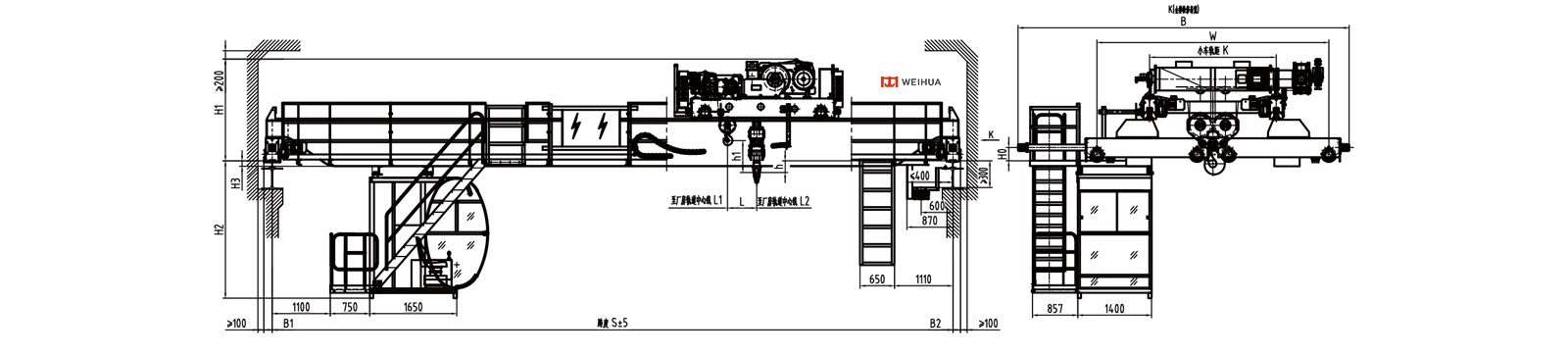

| Capuchon | 3~100 tonnes, sur mesure |

| La portée | 4,5~31,5 mètres, sur mesure |

| Hauteur de levage | 3~30 mètres, sur mesure |

| Matériel de levage | Chariot électrique européen |

| Obligation de travail | A5-A8 |

| Puissance | Sur mesure |

| Température | -20℃~40℃ |

| Taux d'utilisation de l'espace | 90% |

| Pression des roues | 10-50KN |

| Fonctionnement de la vie | >30 ans |

| Pression atmosphérique | Pression atmosphérique standard |

N'hésitez pas à nous laisser un message. Nous vous répondrons dans les 24 heures.

Soumettre une demande