Ponts roulants

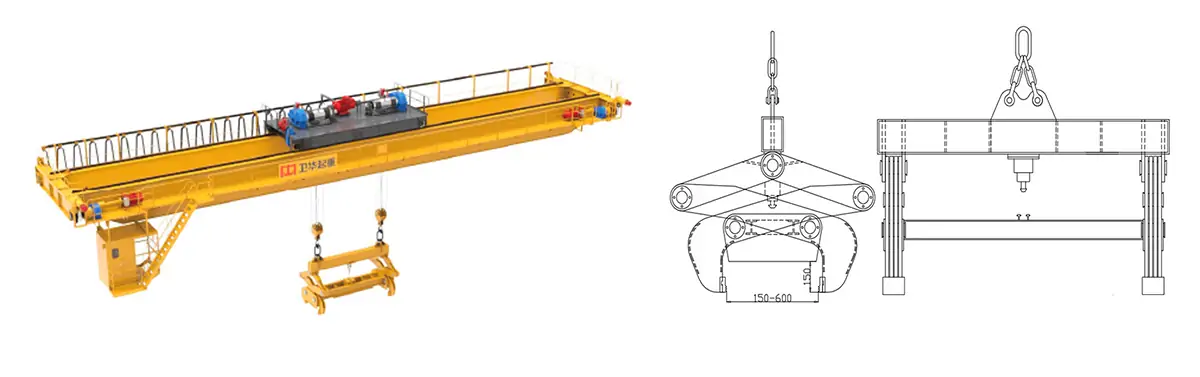

Overhead slab handling crane equipment, also called a billet crane. It is a heavy-duty handling equipment, specially designed for continuous casting and rolling production lines in the iron and steel industry, which is mainly used for transferring, stacking, loading, and unloading of high-temperature and normal-temperature slabs. The equipment can adapt to high temperature working conditions above 650℃ and meet the lifting requirements of slabs or blooms with a thickness of ≥150mm. It is widely used in key production areas such as continuous casting billet span, billet storage, heating furnace, and finished product storage.

According to the structural form, slab handling cranes can be divided into three categories: rigid, flexible, and slewing, and the rated load of the hoisting mechanism includes the weight of slabs, the weight of clamps, and the weight of guide cylinders.

The overhead slab handling crane is mainly composed of a load-bearing structure, a trolley running mechanism, a hoisting mechanism, a spreader system, an intelligent electrical control system, an auxiliary system, and so on. Please see the following introduction:

Ingot, slab, and billet cranes are heavy metallurgical overhead cranes equipped with high-power drive systems and high-temperature-resistant spreaders, which are specially used for the transfer and process connection of high-temperature metal materials. The equipment grabs ingots, slabs, and other materials in high temperatures above 650℃ through special clamps or electromagnetic suction cups for efficient connection between continuous casting, rolling, heat treatment, and other processes. The operation process consists of three key stages: firstly, the high-temperature billets are removed from the billet area of the continuous casting machine, then they are transferred to the heating furnace or rolling mill rollers for re-processing, and finally, the finished products are transported to the slow cooling area or storage area.

This slab crane is designed for efficient and secure handling of heavy billets, featuring adjustable clamps that can be configured either perpendicular or parallel to the beam for versatile load positioning. Below are the key parameters for each clamp orientation:

| Capacité de levage | La portée | Hauteur de levage | Obligation de travail | Vitesse de levage | Crane Traveling Speed | Vitesse de déplacement du chariot | Track |

|---|---|---|---|---|---|---|---|

| 35 ton | 27.5 m | 12 m | A7 | 1.2~12 m/min | 4.2~42 m/min | 8.5~85 m/min | QU120 |

| 50 ton | 37 m | 12 m | 0.95~9.5 m/min | 3.8~38 m/min | 8~80 m/min | ||

| 65 ton | 35.5 m | 12 m | 0.78~7.8 m/min | 3.8~38 m/min | 7.5~75 m/min |

| Capacité de levage | La portée | Hauteur de levage | Obligation de travail | Vitesse de levage | Crane Traveling Speed | Vitesse de déplacement du chariot | Track |

|---|---|---|---|---|---|---|---|

| 35 ton | 27.5 m | 12 m | A7 | 0.95~9.5 m/min | 3.8~38 m/min | 8.5~85 m/min | QU120 |

| 50 ton | 37 m | 12 m | 0.95~9.5 m/min | 3.8~38 m/min | 8~80 m/min | ||

| 65 ton | 35.5 m | 12 m | 0.78~7.8 m/min | 3.8~38 m/min | 7.5~75 m/min |

As a leading heavy-duty overhead slab handling crane manufacturer and supplier in China, Weihua Group has deep technical deposits and rich project experience in the field of metallurgical cranes. It has successfully provided high-performance customized solutions for many domestic and foreign steel enterprises, including:

Our professional team offers a comprehensive range of services, from design and manufacturing to installation and commissioning, tailored to meet the demanding requirements of high-temperature working conditions, precise positioning, and heavy loads. If you need to customize efficient and reliable steel mill crane solutions, please contact Weihua Group's technical team, and we will provide you with the most optimized equipment configuration and technical support.

N'hésitez pas à nous laisser un message. Nous vous répondrons dans les 24 heures.

Soumettre une demande