Noticias del sector

Gantry cranes are mainly used for loading and unloading goods and lifting large components in ports, freight yards, construction sites, and other open places. This article will give you an in-depth understanding of the gantry overhead crane's definition, structural composition, design points, functional features, and the difference with the Overhead Crane. If you don't know how to choose the right Gantry Crane or want to know its price range and application areas, this article will be your ideal guide.

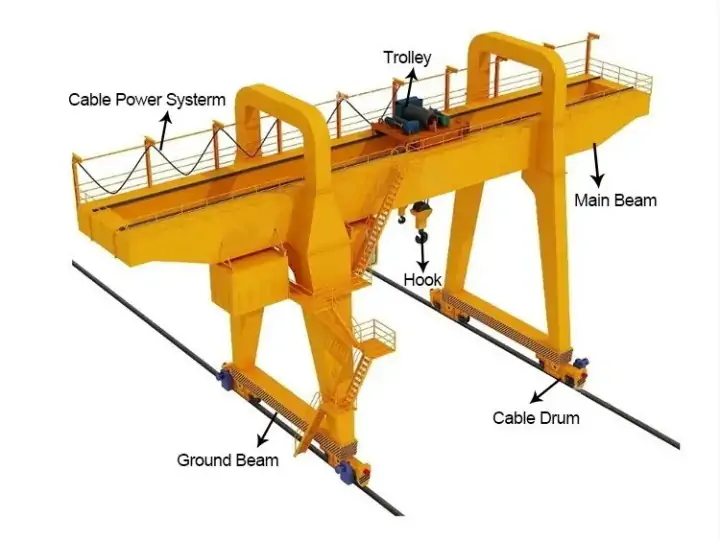

Gantry cranes have a gantry frame structure, consisting of a main beam spanning horizontally, outriggers supported vertically on both sides, and other structures such as a lifting mechanism. Its outriggers and main girder form a solid portal frame structure, so it is called a gantry overhead crane. Longitudinal movement is realized through the rail travelling mechanism, and is equipped with auxiliary facilities such as a driver's room and a windproof device etc. The overall design is of large span and strong rigidity, which is suitable for heavy lifting and loading/unloading operations in ports, stockyards, and other open-air places.

Gantry cranes are mainly used in large-scale material handling, hydropower engineering, railroad manufacturing, and other projects, with a variety of functions, which can effectively complete the loading and unloading of heavy goods, handling, and stacking.

A Gantry crane is composed of a main beam, outriggers, trolley running mechanism, lifting mechanism, cab, ladder and platform, buffer, and other components. The functional characteristics of each part are as follows:

Weihua, as a professional gantry overhead crane manufacturer and customizer, has multiple different types of gantry mounted cranes. If you still don't know which type of gantry crane can enhance the productivity of your factory. The following article will bring you a comprehensive understanding of the different types of gantry cranes and their application scenarios.

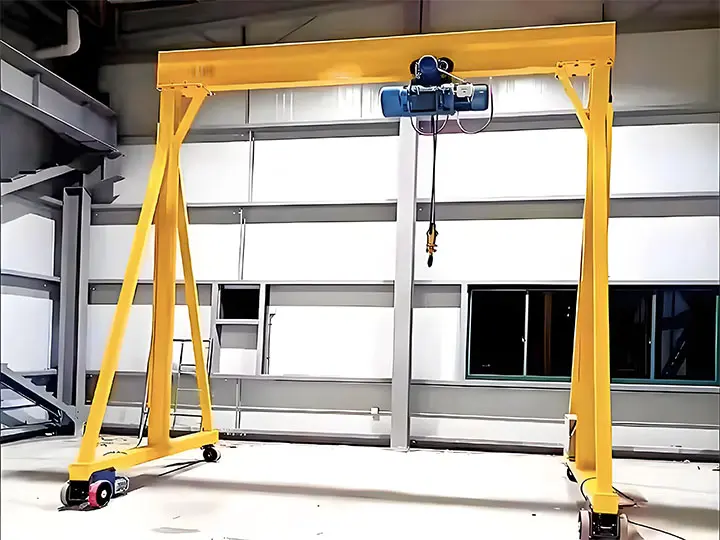

Small portable gantry crane: A Small portable gantry crane is an economical and flexible light lifting equipment. Equipped with universal wheels with braking function, it can move flexibly on different floors and easily adapt to a variety of operating environments.

Grúa semipórtico BMG: The BMG semi gantry crane consists of two main beams, an electric trolley, and a supporting leg on one side. Adopting this structure of a gantry crane can fully utilize the site space.

Grúa de pórtico de una viga MH: The Grúa de pórtico de una viga MH is a small gantry crane with an electric hoist as the lifting system and with rail travelling. This type of gantry crane is popular for its compact structure, easy operation, and small footprint.

Truss Gantry Crane: The truss gantry crane is a light lifting equipment for a specific working environment. The gantry-style column design not only gives the entire structure a unique appearance but also enhances stability by reducing wind resistance.

Grúa pórtico europea de dos vigas: The European double beam goliath crane adopts the advanced European FEM standard design and manufacturing. Compared with the ordinary MG type, its main features are the use of European standards, a hardened surface of the reducer, a three-in-one drive, and PLC+frequency conversion control technology.

RTG Rubber Tyred Gantry Crane: The Rubber Tyred Gantry overhead Crane (RTG for short) is a kind of special lifting equipment dedicated to stacking operations in container yards. RTG integrates automation technology, such as an automatic positioning system and an anti-sway control system, which effectively improves the safety and efficiency of operation.

Rail Mounted Gantry Crane: The rail mounted gantry crane is applicable to remove, load, and unload international standard containers. It is a highly efficient loading and unloading equipment, mainly for in ports, docks, and inland container yards. The main function is stacking, handling, and transshipment of containers from ships to land transport.

| Types | Capacidad | Span | Aplicación | Price Range |

|---|---|---|---|---|

| Smal portable gantry crane | 0.5-10tons | 2-12M | Suitable for garages and workshops, often used for lifting and moving light materials. | $1300 ~ $13000,depending on specifications |

| Semi gantry crane | 10-100tons | 7.5-25.5M | Applicable to mine ports, railway freight stations, open-air warehouses. | $12000 ~ $177000,depending on specifications |

| Grúa de pórtico de una viga MH | 5-30tons | 7.5-30M | Suitable for construction sites, logistics warehousing and other occasions. | $13500 ~ $54700,depending on specifications |

| MH Single Girder Truss Gantry Crane | Suitable for light industrial production, mechanical assembly operations, etc. | $13000 ~ $54000,depending on specifications | ||

| European Double Beam goliath crane | 10-100tons | Usually, it is in steel metallurgy, hydro-power, aerospace, ships, automobiles, coal, petrochemicals, etc. | $22000 ~ $208000,depending on specifications | |

| RTG Rubber Tyred Gantry Crane | 35-70tons | 23/26M | It is mainly used for lifting, moving and stacking containers, and is widely used in ports and large logistics centers, etc. | $950680 ~ $1900875,depending on specifications |

| Rail Mounted Gantry Crane | 30.5-50tons | 26/30/35M | Mainly used in ports, docks and inland container yards. | $494000 ~ $778250,depending on specifications |

The power source of a gantry overhead crane is a multi-system collaborative system driven by electricity or hydraulics. It usually uses an industrial power grid or a diesel generator as the main power source, transfers energy to various components through electric motors or hydraulic pump stations, and is assisted by frequency converters, reducers, and transmission components to achieve precise control and power transmission. Each type of power supply for a gantry crane has its features and advantages. If you have any need for a gantry crane sliding line, conductor line busbar, or cable reel, please feel free to contact us.

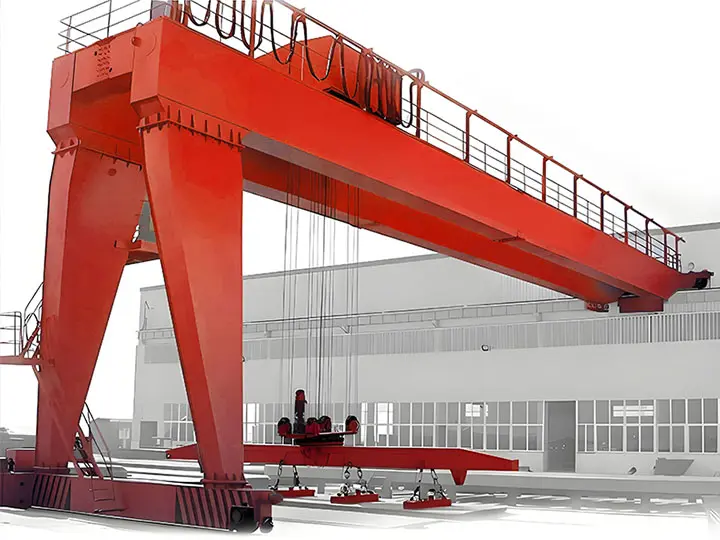

Goliath Crane consist of an A-type or rigid outrigger-supported beam structure and typically run on ground tracks or wheels. The overall design has a large span and strong rigidity, and is suitable for lifting and loading, and unloading operations in open-air places such as port container stacking, large construction sites, and material yards. In contrast, an overhead crane bridge along the track laid on both sides of the elevated longitudinal run, you can make full use of the space under the bridge for lifting materials, for material handling in limited spaces.

Gantry overhead crane specifications and key parameters include:

| Modelo | RTG Rubber Tyred Gantry Crane | |||

| Capacidad de elevación nominal (toneladas) | 35 | 41 | 70 | |

| Distancia base (metros) | 7 | 7 | 7.5 | |

| Span (Metro) | 23.47/26 | 23.47/26 | 23.47/26 | |

| Altura de elevación (metros) | 15.5/18.5 | 15.5/18.5 | 15.5/18.5 | |

| Apilar capas | 4/5 | 4/5 | 4/5 | |

| Especificación del contenedor | 20',40',45' | 20',40',45' | 20',40',45' | |

| Velocidad | Elevación (carga completa/carga vacía) | 20/40 | 25/50 | 25/50 |

| Desplazamiento del pórtico (carga completa/carga vacía) | 30/130 | 30/130 | 30/130 | |

| Viajar en tranvía | 70 | 70 | 70 | |

| Números de rueda | 8 | 8/16 | 16 | |

| Carga máxima por rueda | 300 | 320/180 | 200 | |

| Fuente de alimentación | Grupo electrógeno diésel o trifásico AC380V 50Hz | |||

The main advantages of gantry overhead cranes are their wide operating range, high carrying capacity, and the ability to efficiently carry heavy goods.

Customized gantry mounted cranes are mainly designed according to the specific needs of the user, such as the specific working environment, load requirements, and so on. Key parameters for customization include:

Gantry mounted cranes usually have a lifting capacity ranging from 1 ton to 100 tons. Their tonnage can also be customized according to different usage requirements. Their sturdy structure and design enable them to carry extremely heavy loads, making them ideal for ports, open warehouses, steel mills, and other manufacturing industries.

WeiHua, a well-known gantry overhead crane manufacturer, has a production base of 3,420,000 square meters since its establishment in 1988, and exports its products to more than 170 countries and regions. We have a team of 1,000 R&D engineers and have been awarded 500 honors. We provide one-stop solutions from customized design and installation services to technical guidance, and all products enjoy a one-year warranty service. Our professional and experienced sales team is committed to providing customers with detailed product information to help them make informed choices.

This article has given you a better understanding of gantry overhead cranes. Whether you're looking for a customized solution to fit your needs or wish to learn more about the different types of gantry cranes, we hope to provide you with a valuable reference.

We not only manufacture and supply gantry cranes, but also provide diversified material handling and lifting customized solutions, including transfer carts and lifting platforms according to customers' needs. If you have any specific requirements or need further assistance, please feel free to contact our team of experts, who will provide you with customized solutions and professional support.

Enviar solicitud