Industry News

Port gantry cranes are specialized port equipment used for loading and unloading container ships. They are widely used in container handling operations at coastal ports, docks, and inland ports. As the core hub of ports and storage yards, the performance of gantry cranes directly determines operational efficiency and core competitiveness. As a leading OEM manufacturer, Weihua Group focuses on providing you with a full range of technologically advanced, rugged, reliable, and future-proof port gantry crane solutions.

The primary classification of port gantry cranes includes two types: rubber-tyred gantry cranes and rail-mounted gantry cranes.They are core equipment for modern container terminals, storage yards, and multi-purpose ports.

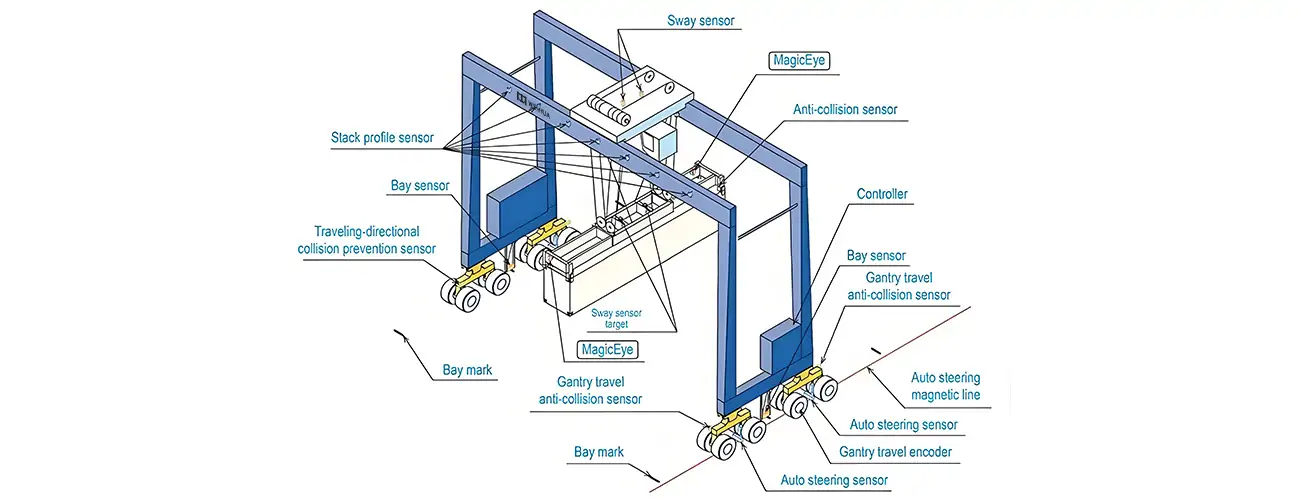

A rubber-tyred gantry crane (RTG) is a specialized lifting device designed for container yard stacking operations. Primarily used for lifting, handling, and stacking containers, it is widely used in ports, large logistics centers, and other locations. Using rubber tires as a running mechanism, RTGs offer high maneuverability within the yard, enabling rapid movement between rows and columns to accommodate busy loading and unloading operations.

Compared to rail-mounted gantry cranes (RMGs), RTGs offer unparalleled maneuverability and adaptability to ever-changing yard layouts. Their robust design, environmentally friendly features, and flexible adaptability have made them a cornerstone of modern container logistics.

A rubber-tyred gantry crane consists of a gantry support, power transmission system, hoisting mechanism, operating mechanism, trolley operating mechanism, small trolley operating mechanism, and a dedicated container spreader. The functional characteristics of each component are as follows:

The heavy-duty steel frame supports the entire machine and provides a workspace. It typically utilizes a box-beam design, offering high strength and excellent torsional resistance.

Mostly utilizes a diesel-electric hybrid or pure electric drive system, equipped with variable frequency control for efficient energy conversion and smooth speed regulation.

Comprising a motor, reducer, drum, and wire rope, it utilizes a dual- or multi-drum design to support rapid container lifting and lowering. Load sensors and height limiters provide precise positioning and overload protection.

It utilizes a tire-based design with either a hydraulic or electric drive system. It offers multiple steering modes to accommodate flexible on-site transport. Some models are equipped with an automatic yaw correction system.

Controls the machine's longitudinal movement along the yard. It utilizes a multi-wheel balance beam structure to distribute wheel pressure and minimize damage to the yard floor. It also features anti-collision and anchoring devices.

This mechanism drives the spreader horizontally along the main beam, using rack and pinion or wire rope traction. Combined with a precision positioning system (such as laser ranging), the spreader's positional accuracy relative to the container is ≤±10mm.

The standard rotary locking device allows for automatic or manual locking of container corner fittings. It supports a variety of container sizes from 20ft to 45ft. Some spreaders also feature integrated weighing and tilt angle detection.

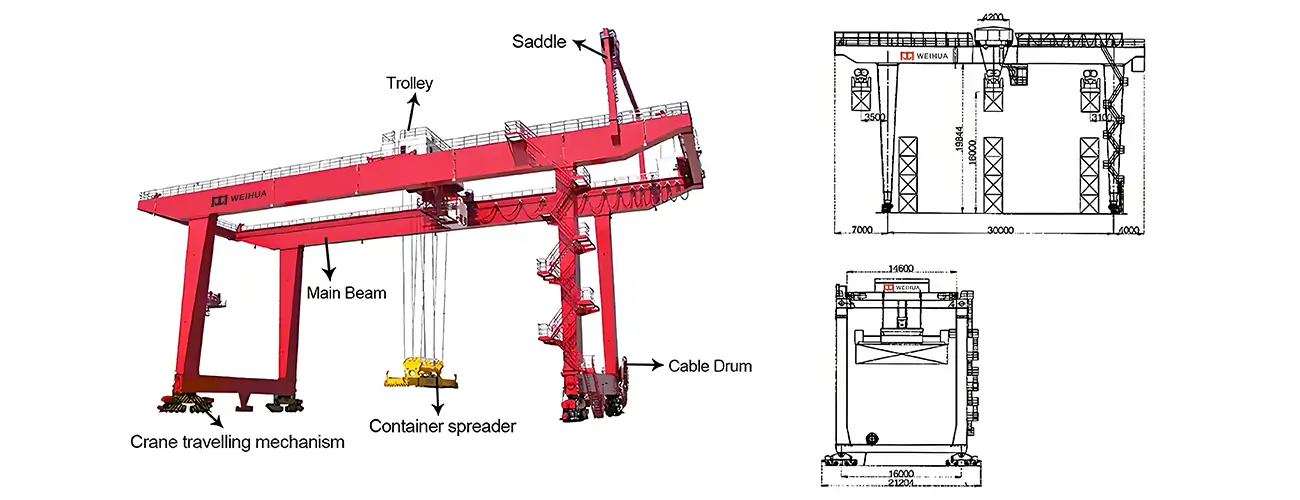

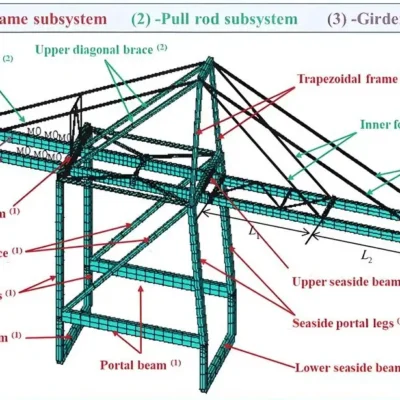

Rail-mounted gantry cranes are suitable for loading and unloading international standard containers. They are highly efficient loading and unloading equipment, primarily used in ports, terminals, and inland container yards. Their primary function is to stack, transport, and transship containers from ships to land. The main girder is the core structure that supports the weight of the container. To ensure strength, the main girder typically adopts a box-section. The outriggers are connected to each end of the main girder. This supports the entire rail-mounted gantry crane and enables its movement along ground tracks.

Compared to rubber-tired gantry cranes (RTGs), rail-mounted gantry cranes (RMGs) operate on fixed tracks, offering greater positioning accuracy and load capacity, making them suitable for dense storage. While their mobility is limited, they excel at long-term, stable operations in fixed sites, while RTGs offer the flexibility of yard mobility.

Thailand Rail Mounted Container Gantry Crane Project

The rail-mounted gantry crane is mainly composed of metal structure (main beam, outriggers, trolley), lifting mechanism, trolley running mechanism, car running mechanism, electrical control system, safety protection device, etc.

Tired gantry cranes (RTGs) are equipped with tires, enabling them to move across a wide range of terrain, sites, and work locations, offering exceptional maneuverability. This allows them to easily transport containers between different yards. In contrast, rail-mounted gantry cranes (RMGs) operate on rails, limiting their mobility to these fixed rails. Consequently, they are limited to linear movement and cannot perform yard transfers.

RTGs generally have lower acquisition costs, and their mobility allows them to adapt to a variety of working environments, thereby increasing equipment utilization. While RMGs may require a higher initial investment, their efficiency and operational stability make them more cost-effective in the long run.

Rigid gantry cranes (RTGs) are suitable for lifting operations between different sites, meeting the needs of diverse locations. Rail-mounted gantry cranes (RMGs) are more suitable for high-intensity, high-efficiency operations in fixed work areas such as ports, terminals, and railway yards.

In summary, both rubber-tired gantry cranes (RTGs) and rail-mounted gantry cranes (RMGs) are essential components of container handling equipment in the shipping industry. Each has advantages and capabilities that make it the ideal choice for specific jobs. Whether it’s the flexibility of an RTG or the precision of an RMG, choosing the right equipment ensures efficient and streamlined workflows, allowing you to move your cargo quickly and reliably.

| Types | Lifting Capacity | Configure | Price Range |

| Rail-Mounted Gantry Crane (RMG) | 35-80 ton | Double girder construction with fixed rail operation | $120,000 - $400,000 |

| Precise movement and positioning of containers | |||

| Automatic deflection correction system | |||

| Rubber-Tyred Gantry Crane (RTG) | 40-100 ton | Rubber tire movement | $700,000 - $3 million |

| Hydraulic steering system | |||

| Frequency conversion speed control |

Now you must have a more comprehensive understanding of RTG and RMG container gantry cranes, and know how to choose the right one to improve your work efficiency.

As a globally renowned crane manufacturer, Weihua is committed to providing customers with optimally priced port gantry crane solutions. We offer a wide range of specifications and configuration options tailored to your specific needs to meet diverse operational requirements.

If you're considering investing in a port gantry crane that can improve efficiency and safety, Weihua is your ideal partner. Contact us today for a free quote.

Date:

Date:

Submit Request