رافعات الموانئ

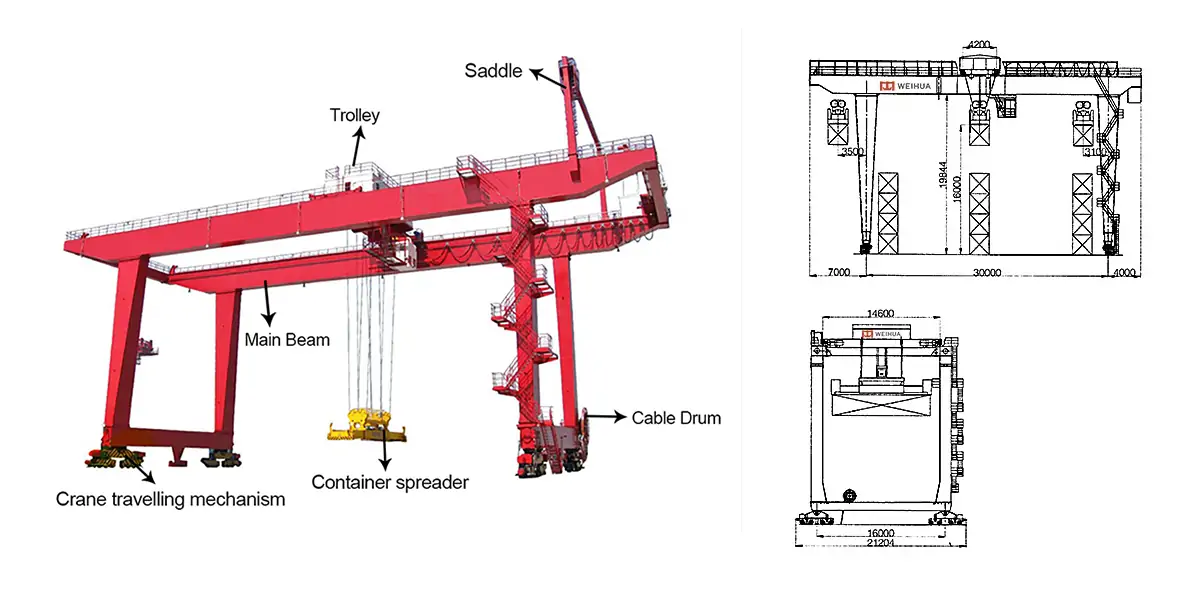

The rail mounted gantry crane is applicable to remove, load, and unload international standard containers. It is a highly efficient loading and unloading equipment, mainly for in ports, docks, and inland container yards. The main function is stacking, handling, and transshipment of containers from ships to land transport. The main beam is the core structure that bears the weight of the container. It is usually a box-shaped section to ensure strength. Its outriggers connect to both ends of the main beam. Thus, it could support the entire RMG crane and allow it to move along tracks on the ground.

يعتمد المحرك الكهربائي على تقنية فريدة لتحويل التردد المتردد الرقمي الكامل والتحكم في تنظيم السرعة PLC مع التحكم المرن والدقة العالية. تضمن المكونات القياسية التي يتم شراؤها من العلامات التجارية المعروفة في الداخل والخارج الجودة الشاملة.

The design, manufacture, and inspection comply with Chinese standards and international standards such as FEM, DIN, IEC, AWS, etc. Weihua’s RMG has the characteristics of multiple functions, stability, reliability, a wide range of operation, easy operation, and maintenance.

Our main products include RMG for railways: upper rotating (trolley rotation), lower rotating (spreader rotation), cantilevered, and non-cantilevered.

Rail mounted gantry crane mainly consists of a metal structure (main beam, outrigger, traveling cart), hoisting mechanism, trolley running mechanism, trolley running mechanism, electrical control system, and safety protection devices.

| سعة الموزع | طن | 30.5 | 35 | 40.5 | 50 | ||

| واجب العمل | أ6 | أ6 | أ6 | أ6 | |||

| امتداد(م) | متر | 35 | 35 | 35 | 35 | ||

| القاعدة(م) | متر | 16 | 16 | 16 | 16 | ||

| ارتفاع الرفع (م) | متر | 15.4 | 15.4 | 18.3 | 18.3 | ||

| سرعة | رفع | مع حمولة كاملة | م/دقيقة | 12 | 12 | 18 | 18 |

| Max. working Lcad of Wheel | 24 | 24 | 36 | 36 | |||

| عربة السفر | 60 | 60 | 70 | 70 | |||

| السفر عبر الجسر | 45 | 45 | 45 | 45 | |||

| إجمالي الطاقة | كيلوواط | ~200 | ~230 | -255 | ~300 | ||

| Max. working load of Wheel | كيلو نيوتن | 260 | 260 | 280 | 300 | ||

| سكة الرافعة | بي 50 | بي 50 | بي 50 | كيو80 | |||

| مزود الطاقة | تيار متردد ثلاثي الطور 50 هرتز 380 فولت | ||||||

| قدرة الرفع | Span range | Price range ($) |

|---|---|---|

| 30 ton rail-mounted gantry crane | 22m-30m | 250,000 - 320,000 |

| 50 ton rail-mounted gantry crane | 22m-32m | 400,000 - 460,000 |

| 60 ton rail mounted gantry crane | 22m-32m | 500,000 - 660,000 |

لا تتردد في ترك رسالة. وسوف نقوم بالرد خلال 24 ساعة.

إرسال الطلب