Pontes rolantes

QD Double Girder Hook Overhead Crane is a kind of heavy-duty industrial overhead crane, which adopts a double main girder structure and is equipped with hooks as spreaders to realize precise lifting and horizontal movement. It is widely used in factories, warehouses, steel mills, hydropower stations, and other places for lifting and handling materials.

Weihua is a professional overhead crane manufacturer, provides one-stop customized solutions for QD double girder hook overhead cranes. Whether it's customized design for special working conditions or high safety standard lifting equipment, we can tailor-make it according to your specific needs and site conditions. Feel free to contact us to get customized solutions for your business.

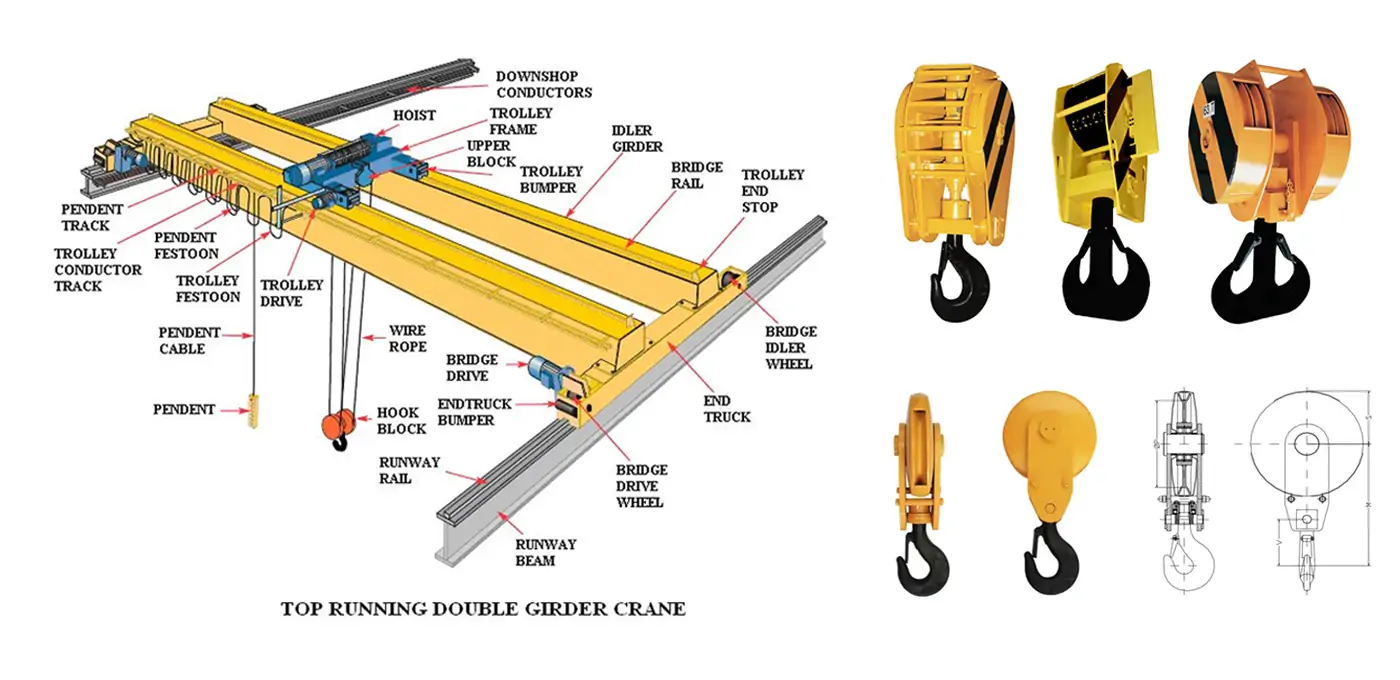

Hooks for overhead cranes can be categorized into 4 types depending on the structure, application, and industry standards. When customizing a hook overhead crane, please choose the right hook according to the requirement. Below are the characteristics and applications of each hook type:

Standard single crane hook block design, simple structure, low manufacturing cost, DIN/ISO compliant, safety factor ≥4 times. Suitable for a wide range of routine lifting operations, wide load range (0.5~300 tons), optional forged or laminated structure, and high durability. Widely used in daily material handling in factories and warehouses, construction sites (steel reinforcement, prefabricated parts lifting), bulk cargo loading and unloading in ports and logistics centers.

Built-in precision bearings can rotate 360° freely to prevent wire rope entanglement, and adopt double-row angular contact bearings with strong axial and radial load carrying capacity. Some models are equipped with servo control to realize precise positioning (±0.5°), suitable for high-precision lifting or long material anti-rotation requirements. Widely used in shipbuilding (steel plate, pipeline lifting), wind power generation (blade installation), automated production lines (need to be accurately aligned), and so on.

Adopting high-strength alloy steel and optimized structural design, the weight is reduced by 15%~20% but the strength remains unchanged; it complies with the latest FEM/ISO standards and has a higher safety coefficient. Widely used in high-end manufacturing (aerospace, automotive assembly), intelligent warehousing and logistics (automated lifting systems), heavy machinery (requires high-strength, lightweight hooks), and so on.

Designed for electric/manual hoists with standardized interfaces; compact design for small spaces (e.g., low-rise plants); optional quick release design for easy spreader replacement. Widely used in workshop light lifting (1~20 tons), maintenance work (equipment dismantling), production line material transfer (with hoist), etc.

Hook overhead crane mainly consists of five core components: metal structure, hoisting mechanism, operating mechanism, electrical system, and safety device.

The trolley travel mechanism is on both ends of the bridge. It can drive the overhead crane along the factory or dock along the rails. This allows the overhead crane to adjust its working position over a wide range. The trolley moves along the rails, which allows flexible positioning of the lifting mechanism. It is responsible for the vertical lifting and lowering of heavy loads. This ensures smooth and safe lifting thanks to a precise transmission system and a braking device. The electrical system provides power to each mechanism of the overhead crane. It also precisely controls its operation, including motors, controllers, limit switches, etc., to ensure safe and accurate operation.

| Modelo | Tipo QD | |||||||||||

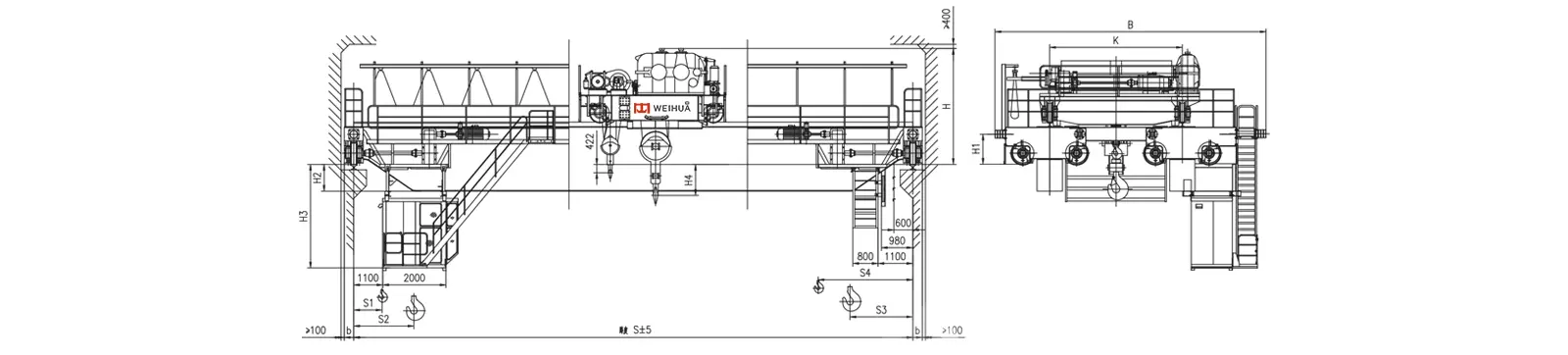

| Capacidade de elevação | t | 5 | 10 | 16/3.2 | 20/5 | 32/5 | 50/10 | 75/20 | 100/20 | |||

| Altura máxima de elevação | Levantamento principal | m | 16 | 16 | 16 | 12 | 16 | 12 | 20 | 22 | ||

| Max. lifting height | m | 18 | 14 | 18 | 16 | 22 | 22 | |||||

| Span | m | 10.5-31.5 | 13.5-31.5 | 13-31 | ||||||||

| Velocidade de elevação | Principal | m/min | 11.3 | 8.5 | 7.9 | 7.2 | 7.5 | 5.9 | 6.1 | 3.9 | ||

| 15.6 | 10.4 | 10.7 | 9.8 | 9.5 | 7.8 | 6.1 | 4.9 | |||||

| Aux. | 14.6 | 15.5 | 15.5 | 10.4 | 7.2 | 7.2 | ||||||

| Velocidade de deslocação do trólei | m/min | 37.2 | 37.2 | 40.0 | 40.0 | 42.6 | 38.5 | 38.4 | 33.90 | |||

| Velocidade de deslocação da grua | A5 | m/min | 68.3/70.4 | 70.4/71.8/73.4 | 70/72/72.8 | 70/72/73 | 74.2/75.1 | 75/75/72 | 53.9 | 61.7 | ||

| A6 | 68.3/71.1/88.9 | 71.1/74.2/74.2 | 70/72/73 | 71.3/73.6/73.6 | 75 | 75/75/74 | 77.8/67 | 61.8 | ||||

| Fonte de alimentação | 3 Frase C.A. 50Hz 380V ou outros | |||||||||||

QD overhead traveling cranes are popular in indoor and outdoor industrial and mining facilities, the chemical industry, ferrous metallurgy, railway transportation, ports and terminals, as well as in logistics warehouses, and many other areas.

In the workshops of industrial and mining enterprises, double-girder hook overhead cranes can lift raw materials, semi-finished products, and finished products. This can greatly contribute to the efficient operation of the production process.

For steel and chemical plants, it can move heavy equipment, steel, and chemical raw materials.

No transporte ferroviário, pode ajudar na carga e descarga de mercadorias. Nos terminais portuários, é uma ferramenta poderosa para carregar e descarregar mercadorias, levantar e transportar contentores e mercadorias a granel. Nos armazéns logísticos, pode tratar eficazmente do armazenamento e transbordo de vários tipos de mercadorias.

A hook crane lifts loads using rigging attached to a mechanical hook, suitable for all material types. A magnetic crane uses magnetic force to lift metal objects directly, without slings or chains.

Hook cranes are flexible, handling various load shapes and materials. The user can choose the most convenient slinging method for each application: metal rings, cable slings, textile lifting slings, etc. Hook cranes have lower maintenance costs compared to magnetic lifting systems.

The hook approach is the closest distance the crane’s hook can reach from a side wall or obstruction. A smaller hook approach allows for crane and building space can be maximized, and increases productivity.

The hook on a crane is commonly referred to as a crane hook. It’s a forged component that connects the load to the hoisting mechanism via slings, chains, or lifting gear.

Cranes use two hooks—main and auxiliary—to handle loads of varying weight or to support tandem lifting. This improves load control, allows dual-function operations, and boosts overall efficiency.

A hook is the attachment point for lifting a load. A hoist is the entire mechanism that raises or lowers the load, including the motor, drum, and lifting medium (wire rope or chain).

Não hesite em deixar uma mensagem. Responderemos em 24 horas.

Enviar pedido