Gantry Cranes

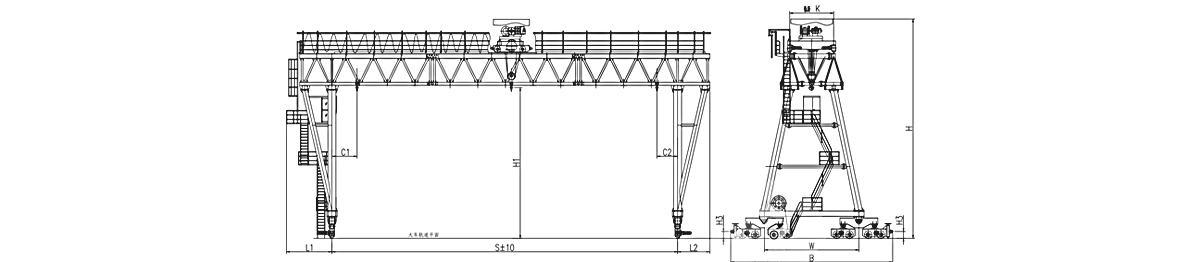

Truss Gantry Crane is a kind of gantry crane that adopts a truss structure as the main girder, the rigid or flexible legs on both sides, and the truss main girder on the top form a gantry frame, which can be moved along the ground track to carry out lifting operations. The truss structure has about 40%-60% air permeability, the wind resistance coefficient is significantly lower than the traditional box girder gantry crane, especially suitable for ports, coastal areas, and other windy places.

The truss structure is usually connected by standardized rods and nodes, which is convenient for factory prefabrication and on-site assembly, easy for inspection and maintenance, and is suitable for engineering occasions requiring frequent disassembling and transferring, such as hydroelectric power station construction, bridge construction, and so on. It is widely used in harbor terminals, bridge construction, power station construction, heavy equipment manufacturing, and other fields.

Truss gantry cranes can be customized according to customer needs, with a lifting capacity of 1~20 tons and a span of 10-60 meters. According to different application scenarios, they can be divided into two major types: single girder and double girder truss gantry cranes.

| Terms | Units | Parameters | ||||

| Loading capacity | t | 40 | 60 | 80 | 100 | |

| Span | m | 20~40 | 20~30 | |||

| Duty group | ISO | A5 | ||||

| Lifting speed | m/min | 1 | 0.95 | 0.8 | ||

| Trolley traversing speed | 10 | 10.5 | ||||

| Crane traveling speed | 14 | 15 | 13 | |||

| Total motor power | kW | 22.8~26 | 30 | 31.4 | 46.4 | |

| Power supply | 3ph 380V 50 Hz or customized | |||||

For detailed product information, please refer to the PDF.

Ports: For loading and unloading of containers, cargo ships, etc., to improve logistics efficiency.

Shipbuilding industry: Hull assembly, disassembly, and other operations, because it can handle very heavy parts.

Steel industry: Suitable for the handling and loading, and unloading of large items such as steel plates and steel.

Water conservancy construction: Including the lifting of heavy equipment and materials in the construction and maintenance of dams, channels, etc.

Mines: used for the transportation and loading, and unloading of resources such as ore and coal.

Lightweight design: adopting a space truss structure, lightweight, low foundation bearing requirement, suitable for large span operation.

Excellent wind resistance: the open truss structure has low wind resistance, strong wind permeability, and good stability, which is especially suitable for open-air environments, such as harbors and wind power installation operations. The stability is better than box crane in high wind speed areas.

Strong large-span capability: the truss structure can realize a large span (4 to 39 meters) by optimizing the grid layout, which is suitable for bridge construction, power station construction, and other scenarios.

Modular assembly: Segmented truss units, connected by bolts or pins, are easy to transport and quickly assembled on site. Suitable for temporary works or frequent moving operations.

High economy: low material consumption and low manufacturing cost, especially suitable for small and medium tonnage demand; and the lightweight design can reduce the investment in supporting equipment (such as rails and motors).

Flexibility to adapt to complex environments: the structure can be customized, such as triangular, diamond truss; adapt to narrow space or special terrain, such as mountainous areas, offshore platforms, and other special working conditions. Easy to maintain, can locally replace damaged units to reduce costs.

Applicable scenarios: port loading and unloading, wind power equipment installation, bridge erection, temporary construction sites, and other occasions that require lightweight, large span, or wind resistance.

This project is designed for the prefabricated girder yard of a high-speed railroad, which is used for lifting and transferring large segmental girders. The customer purchased a total of 22 truss gantry cranes, which include single main girder and double main girder structures, and are used in the whole process of prefabrication, storage, and loading.

The single girder structure is used for small section girder transfer and auxiliary operations.

The double girder crane adopts a double trolley synchronized control system, which can realize four-point balanced lifting to ensure that the section girders remain level during lifting and avoid structural deformation.

| Comparison items | Truss crane | Box crane |

|---|---|---|

| Comparison items | Truss crane | Box crane |

| Structural design | Space truss structure (steel pipe/steel grid), lightweight | Closed box section (steel plate welding), strong rigidity |

| Weight | Light | Heavier |

| Carrying capacity | Small and medium tonnage (usually ≤100 tons) | Large tonnage (up to 1,000 tons) |

| Wind resistance | Low wind resistance, suitable for open air, high wind speed environment | High wind resistance, requiring additional wind resistance design |

| Rigidity/stability | General (depending on truss layout) | High (excellent bending and torsion resistance) |

| Applicable scenarios | Ports, wind power, temporary projects, large span light lifting | Metallurgy, shipbuilding, workshop, heavy precision lifting |

| Manufacturing complexity | Many nodes, complex welding/bolt connections | High requirements for box welding process |

| Transportation and installation | High requirements for the box welding process | Large box beams are difficult to transport and often need to be segmented |

| Maintenance cost | High (need to check nodes regularly) | Low (closed structure, good corrosion resistance) |

| Initial cost | Low (less material consumption) | High (high steel consumption) |

Stringer: suitable for lightweight, large span, frequent movement, or open-air operation, such as wind power, or harbor.

Box: suitable for large tonnage, high rigidity, long-term fixed place, such as metallurgical workshop, nuclear power.

Please feel free to leave a message. We will reply in 24 hours.

Submit Request