Overhead Cranes

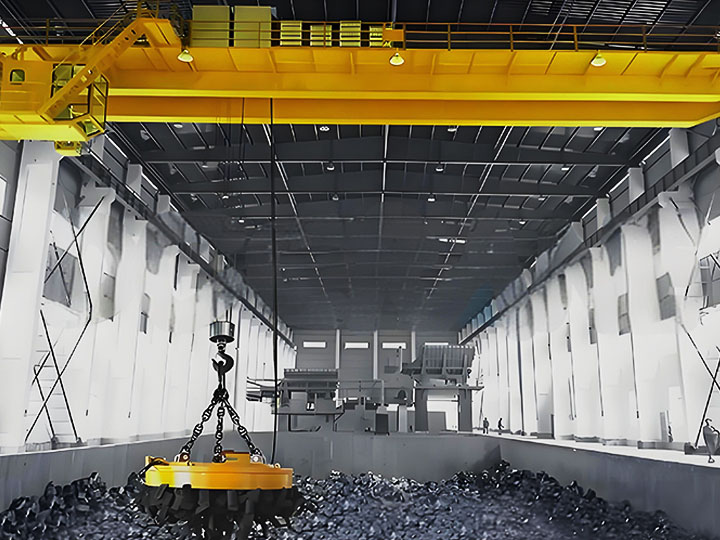

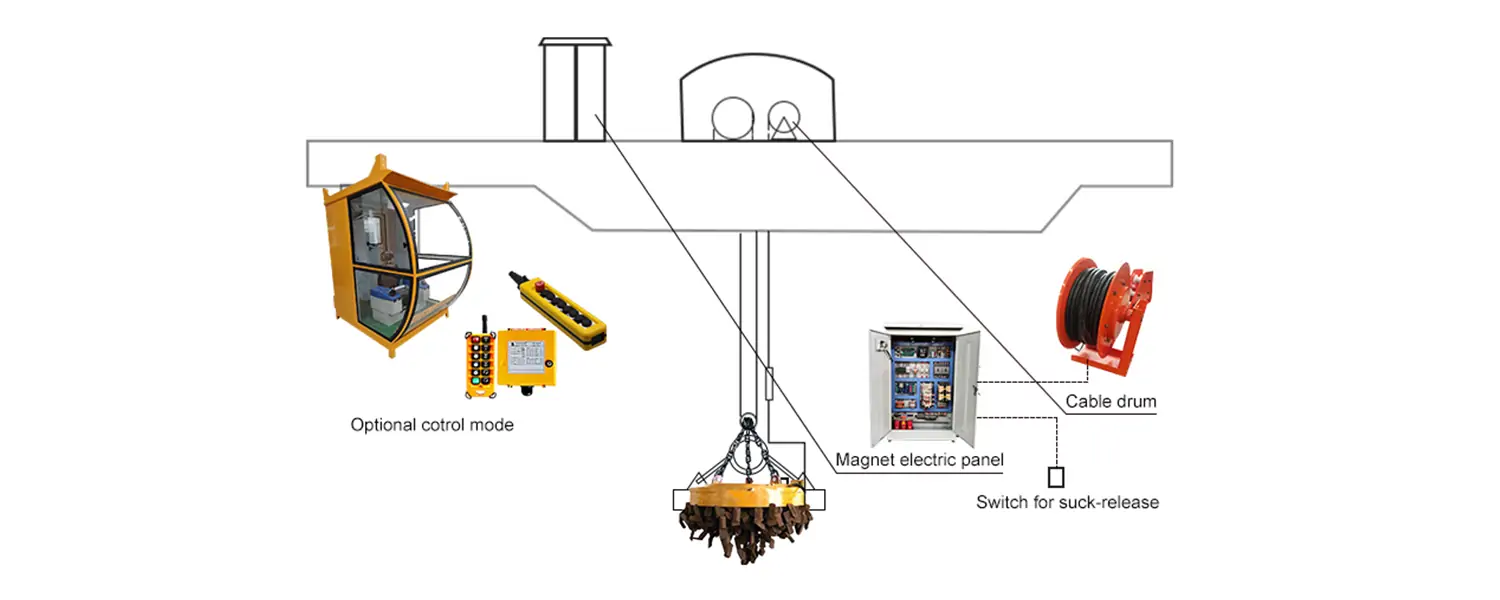

An electromagnetic bridge crane is a double-girder bridge crane equipped with a removable electromagnetic lifting magnet, which uses electromagnetic force to lift and transport metallic materials. It generates magnetic force through an electromagnetic coil to secure the workpiece, then uses the crane's hoisting mechanism for lifting and transportation.

The lifting capacity of the electromagnetic bridge crane ranges from 5 to 32 tons (including the electromagnetic suction cup). The working duty is A5 and A6. The magnetic holding time is 10 to 30 minutes. It is commonly used in steel mills, ports, scrap yards, and other locations requiring large-scale lifting and handling of ferromagnetic materials.

When the electromagnetic lifting magnet of the crane is energized, the internal coil generates a strong excitation current, forming a high-intensity closed magnetic field circuit. This magnetic field effectively penetrates magnetic workpieces, establishing a stable magnetic adhesion connection between the workpiece and the magnet surface. The load capacity ranges from 0.8 to 1.5 tons.

The electromagnetic crane uses a variable-frequency controlled lifting mechanism to lift the electromagnetic lifting magnet with the workpiece attached to the specified position, then perform handling operations.

The QC electromagnetic bridge crane has the advantages of strong magnetic adsorption, efficient handling, and adaptability to harsh environments, making it an ideal choice for industries such as steel, machinery, ports, and scrap recycling. Different industries can choose from traditional electromagnetic suction cups, electrically controlled permanent magnet suction cups (EPM), or special models for scrap steel according to their needs to optimize work efficiency. The following are applications in various industries:

1. Steel and Metallurgy Industry: Used for the handling and stacking of steel ingots, steel plates, and structural steel (such as H-beam steel and I-beam steel), as well as the recycling and transportation of pig iron blocks, scrap steel, and iron shavings. It is also used for the lifting operations of continuous casting billets and hot-rolled/cold-rolled coils. It is designed to withstand high-temperature environments and is suitable for frequent loading and unloading operations.

2. Mechanical Manufacturing and Processing Industry: Used for handling large castings and forgings (such as machine tool bases and engine housings), positioning and installing steel beams and steel plates in metal structure workshops, and recycling scrap materials (such as machining chips and stamping scrap). Suitable for indoor workshops or outdoor yards.

3. Port terminals and logistics warehousing: Used for loading and unloading steel and metal coils onto ships, transferring scrap metal within container terminals, and sorting and storing steel in large warehouses; equipped with rainproof and corrosion-resistant designs (outdoor models come with protective devices).

4. Scrap Metal Recycling Industry: Used for grabbing and sorting scrap steel, scrap iron, and metal from dismantled vehicles, transporting metal scrap on crushing production lines, using specialized electromagnetic clamps for scrap steel with reinforced impact-resistant housings; suitable for irregular materials (e.g., scrap iron, metal shavings).

5. Shipbuilding and heavy equipment manufacturing: Used for lifting ship hull steel plates, large steel structural components, assembling and moving heavy mechanical parts, etc. Some models can be equipped with underwater electromagnetic chucks for shipwreck salvage operations.

6. Power and Energy Industry: Used for the installation of power plant boiler steel frames, pressure vessels, and the lifting of large metal components in nuclear power equipment, etc., requiring multiple safety devices such as emergency power-off magnetic adhesion.

The Electromagnetic Crane has a bridge frame, electric trolley, electrical electromagnetic suction cups, and other vital parts. The bridge is the main part of the whole crane, providing stable support for other parts and bearing loads in the lifting process. The trolley running mechanism makes the bridge crane move flexibly on the rail to expand the operation range. Its electric trolley moves horizontally on the bridge and works in concert with the trolley running. Therefore, it provides precise positioning of the electromagnetic suction cup in space. As the core component, the special design of the electromagnetic suction cup can adsorb the magnetic materials to realize safe and efficient lifting.

The following is a comparison table of the structural characteristics of the main types of electromagnetic lifting magnets:

| Types | Basic Shapes | Features | Typical Application Scenarios |

|---|---|---|---|

| With A Manual Automatic Switch | Round or rectangular flat disc | Multi-layer copper-aluminum coil winding inside | Steel plates, steel coils, large casting handling |

| High-strength steel protective layer on the outer shell | |||

| Pole shoe magnetic pole block design on the bottom | |||

| ElectroPermanent Magnet EPM | Square or rectangular modular design | NdFeB SmCo permanent magnet electromagnetic control module as the core | High temperature workshops, energy-saving demand occasions |

| No continuous power consumption | |||

| Manual rotation lever unloading is required | |||

| Permanent Lifting Magnet | Compact disc or U-shaped | Pure permanent magnet array without coil | Powerless environment, small metal parts handling |

| The aluminum alloy outer shell reduces weight | |||

| The outer shell is usually stainless steel | |||

| Scrap Lifting Magnet | Deep bucket or cone | Thickened manganese steel outer shell | Scrap iron recycling station, crushed material processing |

| Bottom open pole design | |||

| Optional dustproof sealing structure | |||

| Underwater Lifting Magnet | Disc with protective cover | IP68 waterproof seal | Shipwreck salvage, seabed metal recovery |

| Corrosion-resistant stainless steel outer shell | |||

| Special insulated cable interface | |||

| Lightweight Electromagnet | Thin disc or strip | Low-voltage coil design | Robotic arm, automated production line |

| Low voltage coil design | |||

| Integrated temperature sensor |

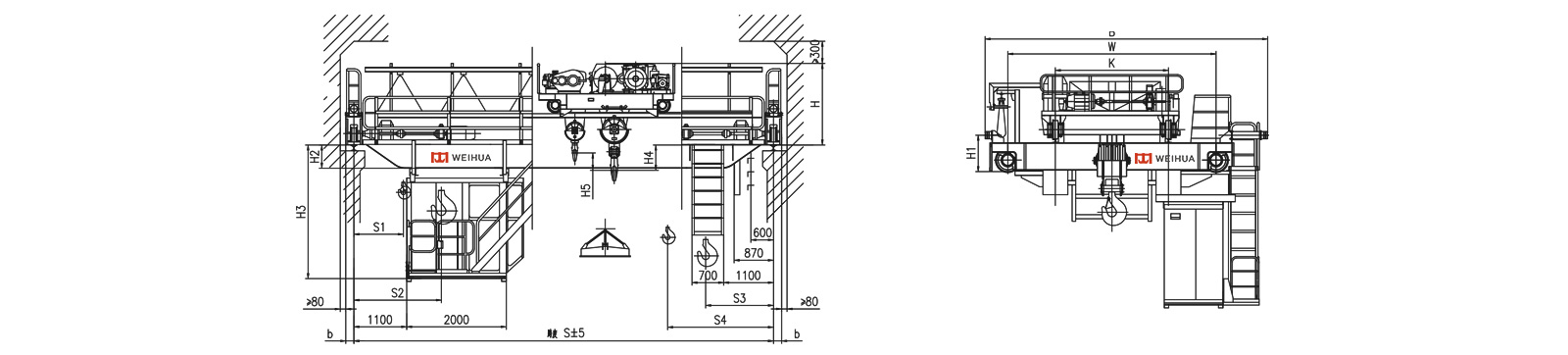

| Model | QC Electromagnetic Bridge Crane | |||||

| Lifting capacity(t) | 16/3.2 | 20/5 | 32/5 | 50/10 | ||

| Span(m) | 10.5-31.5 | |||||

| Lifting height | 16/18 | 12/14 | 16/18 | 12/16 | ||

| Working class | A6 | |||||

| Speed (m/min) | lifting | Electromagnetic | 13 | 9.7 | 9.5 | 7.8 |

| Aux.hook | 14.5 | 12.7 | 12.7 | 13.2 | ||

| Trolley traveling | 44.6 | 44.6 | 42.4 | 38.5 | ||

| Crane traveling | 112.5/101.4 | 112.5/101.4 | 101.8/86.8 | 86.8/87.3 | ||

| Power supply | 380v, 50HZ, 3phase or customized design | |||||

As a leading Electromagnetic Bridge Crane manufacturer, Weihua Crane specializes in providing customized high-performance electromagnetic suction cup bridge crane solutions tailored to our clients' specific operational requirements. With a seasoned R&D team and state-of-the-art production lines, we design fully customized electromagnetic lifting solutions tailored to your specific application needs, including load capacity, span, duty cycle, temperature environment, and more.

Please provide your specific requirements (material type, workshop dimensions, operating temperature, etc.), and our engineers will provide you with the following within 24 hours: 3D layout design proposal, technical specifications and quotation, case studies for reference.

Please feel free to leave a message. We will reply in 24 hours.

Submit Request