Overhead Cranes

The overhead ladle crane is a double girder bridge crane, specially designed for the steel mill and used for lifting molten metal in metallurgy. It is particularly for handling molten metal, hot steel, and other high-temperature materials.

The overall structure can be divided into double girders with double tracks, four grinders with four tracks, four beams with six tracks, and other types. The former two are generally for large-tonnage overhead cranes, and the third one is for foundry cranes with large tonnage. The hoisting mechanism is an electric trolley with multiple brakes for reliable lifting capability and safety. With heat radiation reflectors, overhead ladle cranes have great heat resistance and performance in hot circumstances. In addition, we offer the following optional features: rotary spreader, fixable gantry hook, cargo weighing, and display.

Steel Mill Ladle Crane mainly uses the workshop track direction to achieve longitudinal movement, the trolley to achieve lateral movement, and the crane hook for lifting and lowering operations. This crane is mainly used to lift molten metal and is suitable for ambient temperatures between -10℃ and +50℃, with relative humidity not exceeding 50% at 40℃. To ensure safety, the radiation temperature of the lifted molten metal on the forging hook and plate hook must not exceed 300℃. Ladle Crane's working level reaches A7 and A8, which is very suitable for use in busy metallurgical casting workshops.

As the main equipment of the steelmaking and continuous casting process, the ladle handling crane is mainly used in steelmaking workshops to lift and transport liquid steel ladles near refining furnaces or continuous casting machines. It is also applicable to foundries for handling melted metal and other high-temperature materials.

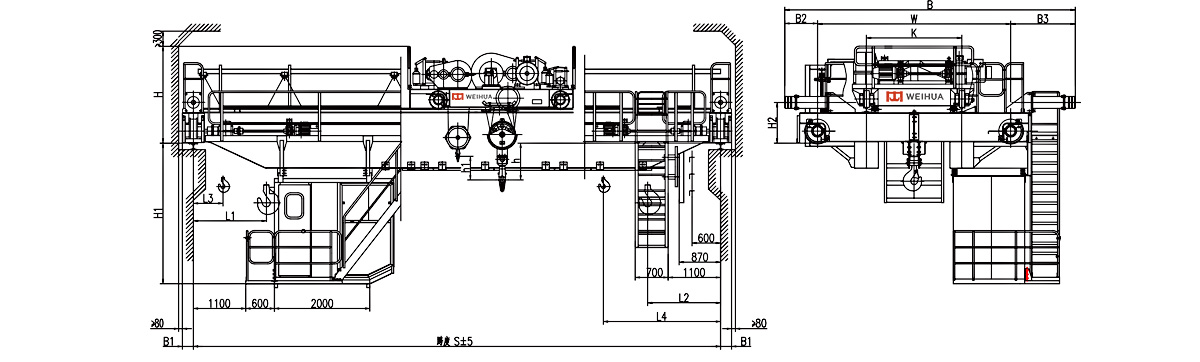

Ladle Crane mainly consists of core components such as the bridge, trolley, main and auxiliary lifting mechanisms, traveling mechanism, spreader system, electrical control system, and safety protection device. The following are the functional characteristics of each component:

Bridge: composed of main beam and end beam, carrying the weight of the whole system, adopting high-strength structural steel, with excellent torsional rigidity and deformation resistance.

Trolley (running mechanism): carries the lifting mechanism, moves longitudinally on the bridge, is equipped with a vibration-damping device, runs smoothly, and is convenient for accurate positioning.

Main lifting mechanism: used for lifting ladle, adopting double drum or four rope structure, with high lifting force and redundant safety, suitable for high temperature and high load working environment.

Secondary lifting mechanism: Used for auxiliary actions such as ladle tilting and pouring to enhance operational flexibility, often integrated into the main lifting trolley.

Spreader system: usually includes a ladle lifting beam or rotating hook, partly equipped with a hydraulically driven rotating device, adapting to different types of ladle operation.

Traveling mechanism: drive the whole crane to move laterally on the track, adopting frequency conversion control to realize smooth acceleration and deceleration.

Electrical control system: centralized control of the whole machine operation, supporting PLC, remote monitoring, and automation operation, improving operation efficiency and safety.

Safety protection devices: including overload protection, limit device, anti-swing system, and high temperature protection measures to ensure safe operation under a high temperature environment.

If you need to customize the structure and configuration of the ladle crane according to your metallurgical working conditions, welcome to contact the Weihua technical team to get the detailed plan.

| Item | QDY overhead ladle crane |

| Loading capacity | 5 ~ 75 ton |

| Lifting height | Customized |

| Lifting speed | Varies with lifting capacity |

| Span | 10.5 ~ 31.5 m |

| Lifting mechanism | Winch trolley |

| Working class | A7/A8 |

| Working temperature | -20 ~ +60 ℃ |

| Power supply | AC-3Phase-220//230380/400/415/440V-50/60Hz |

| Control voltage | DC-36 / 48V |

| Motor protection class | IP54 IP55 IP65 |

| Control way | Cabin, wireless remote, pendant push button |

| Safety device | Factory, workshop, warehouse, power station, logistics,etc. |

| Application area | Factory, workshop, warehouse, power station, logistics, etc. |

| Painting color | Yellow, Red, or Customized |

A ladle crane is a heavy-duty overhead crane designed for handling molten metal in steel mills and foundries. It typically consists of a robust bridge structure, a trolley with main and auxiliary hoisting mechanisms, heavy-duty lifting devices (such as ladle hooks or rotating beams), and advanced control and safety systems. Mainly used for transporting, pouring, and positioning steel ladles with high precision under extreme heat conditions, the lifting capacities range from 50 to over 500 tons.

Please feel free to leave a message. We will reply in 24 hours.

Submit Request