Overhead Cranes

Double Hoist Overhead Crane is a kind of overhead crane equipped with two sets of independent hoisting mechanisms (i.e, double hoist). It consists of main girder, an end girder, two sets of electric hoists (or winch systems), a large trolley operating mechanism, a small trolley operating mechanism, and a control system. The two sets of electric hoists can be installed on the same main girder (parallel or staggered layout) or separately arranged in the double main girder structure to realize cooperative or independent operation.

Double Hoist Overhead Crane can be divided into two main types, Single Girder and Double Girder, according to the main girder structure. They are significantly different in terms of structural design, load carrying capacity, application scenarios, and so on.

Single girder double hoist overhead crane adopts one box girder or I-beam as the main load carrying structure, and two sets of electric hoists (usually wire rope or chain hoists) are mounted on the same main girder. The load carrying capacity is usually 5~20 tons (single hoist) or 10~32 tons (double hoist joint lifting) of load, and the span range is 5~22 meters.

The Double Girder Double Hoist Crane utilizes two box girders or truss girders to provide greater rigidity and load carrying capacity. It is suitable for heavy loads from 20~500 tons or even higher (e.g., metallurgy, shipbuilding industry). The span range is 10~35 meters, suitable for large plants. Common types are LH double girder overhead crane and the NLH European double girder overhead crane.

| Model | LH type | NLH type (European style) |

|---|---|---|

| Applicable scenarios | Light frequent handling (machining, assembly line, small warehouse) | Medium and heavy precision operations (steel processing, heavy installation, logistics warehousing) |

| Lifting capacity | 1~20t | 5~32t |

| Hoist type | CD1/MD wire rope hoist (standard speed) | European hoist (dual speed/frequency conversion, ABB motor + SEW reducer) |

| Control method | Conventional control | Optional frequency conversion/remote control/automation |

| Operation accuracy | General | High (anti-sway, precise positioning) |

| Structural features | Low headroom, low cost | High-strength design, excellent durability |

| Cost | Economical | High (high cost performance) |

Higher stability: double beam structure with better torsion resistance, suitable for precision lifting (such as wind turbine blade installation).

Strong expandability: magnetic spreader, grab bucket, C-hook, and other specialized spreaders can be integrated.

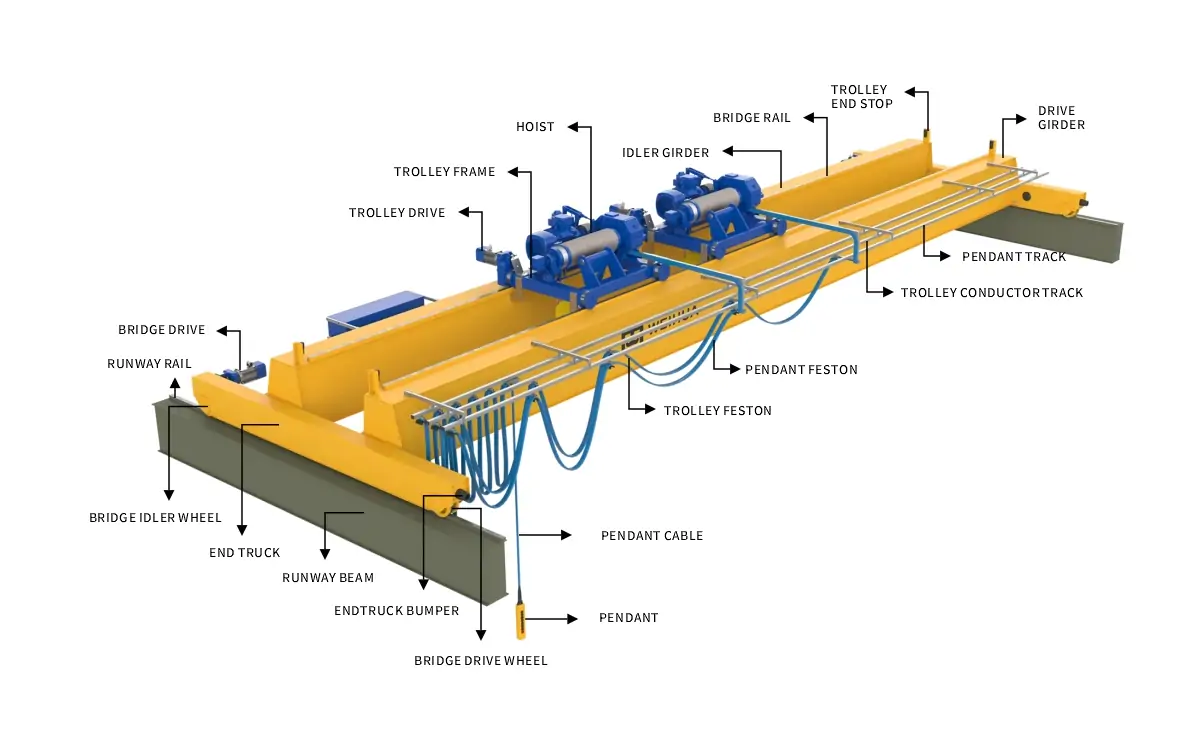

Double Girder Double Hoist Crane consists of main girder structure, end girder, hoisting mechanism (hoist), trolley operation mechanism, large trolley operation mechanism, electrical control system, and safety devices, which is suitable for heavy-duty and high precision lifting requirements.

1. Bridge Girder: carries all the loads and supports the operation of the trolley and hoisting mechanism. It is suitable for large spans (10~35m+) and heavy loads (20~500+ tons).

2. End Trucks: connect the main girder and support the crane to move along the plant rail. Usually adopts a box-type structure, with built-in driving and driven wheels of the trolley. Equipped with a bumper to prevent collision, some models with leveling wheels to reduce track deflection.

3. Hoist Unit: to realize vertical lifting of load, usually equipped with two sets of independent hoists. Such as electric wire rope hoist (large tonnage) or chain hoist (light load, high precision). They can be synchronized for balanced lifting or operated independently. An optional European-style hoist with frequency control for stepless speed regulation and precise positioning is available upon request.

4. Trolley Traveling Mechanism: drives the hoist to move laterally along the main beam for precise positioning of the load. Adopts a three-in-one drive motor (motor + reducer + brake integration), compact structure. Optional anti-sway system (for precision lifting). 5.

5. Bridge Traveling Mechanism: drives the crane to move longitudinally along the plant rail. Four-corner drive (4-wheel active) ensures smooth operation and avoids the phenomenon of “chewing rail”. Heavy crane adopts double-speed or frequency conversion control to reduce the start-stop impact. 6.

6. Electrical System: control crane operation, safety protection, and data monitoring, PLC + frequency converter to realize precise speed regulation and automatic operation, wireless remote control or cab control (according to the working conditions). It can be integrated with load monitoring, limit protection, and fault diagnosis.

7. Safety Devices: to ensure the safety of personnel and equipment. Such as an overload limit or limit switch. Emergency stop button, collision avoidance system, sound and light alarm, windproof anchoring device.

| Model | LH Type Double Hoist Overhead Crane | ||||

| Capacity(ton) | 5 | 10 | 16/3 | 20/5 | 32/5 |

| Span(m) | 10.5-31.5 | ||||

| Lifting Height(m) | 6/9/12/18/Other height | ||||

| Trolley Traveling Speed(m/min) | 20 | ||||

| Model of Electric Hoist | CD1(MD1) | ||||

| Cabin Traveling Speed(m/min) | 20 | ||||

| Crane Traveling Speed-Ground Control(m/min) | 20 | ||||

| Working Class(FEM/ISO) | A3/A4 | ||||

| Power Source | 3 Phase A.C.50HZ 380V | ||||

| Lifting Capacity | T | 5 | 10 | 16/3.2 | 20/5 | 32/5 | 50/10 | ||

| Span | m | 10.5-31.5 | |||||||

| Speed | Main Hook Lifting | A5 | m/min | 11.3 | 8.5 | 7.9 | 7.2 | 7.5 | 5.9 |

| A6 | 15.6 | 13.3 | 13 | 12.3 | 9.5 | 7.8 | |||

| Aux. Hook Lifting | 16.7 | 19.5 | 19.5 | 10.4 | |||||

| Traveling with Crab | 37.2 | 43.8 | 44.6 | 44.6 | 42.4 | 38.5 | |||

| Cabin, remote control; ground handle | A5 | 89.8/91.8 | 90.7/91.9 /84.7 | 84.7/87.6 | 84.7/87.6 | 87/74.2 | 74.6 | ||

| A6 | 92.7/93.7 | 115.6/116 /112.5 | 112.5/101.4 | 112.5/101.4 | 101.4/101.8 | 75/76.6 | |||

| Operational Model | Cabin, remote control, ground handle | ||||||||

| Working Duty | A5,A6 | ||||||||

| Power Supply | Three-phase A.C. 380V, 50Hz or customized | ||||||||

Please feel free to leave a message. We will reply in 24 hours.

Submit Request