Puentes grúa

LB type explosion-proof single girder overhead travelling crane is specially designed for flammable and explosive environments. Its explosion-proof mark is Ex, which conforms to GB3836.1-2000 and GB3836.2-2000 standards. The motor and electrical appliances adopt an explosion-proof design, and the explosion-proof grade can be up to ExdⅡCT4, and the running mechanism has been treated with spark-proofing to ensure safety and reliability.

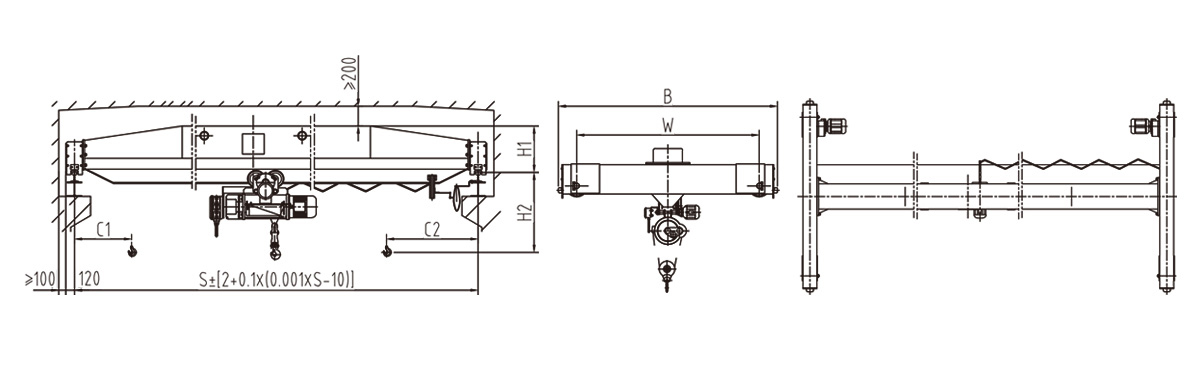

The whole overhead crane strictly follows the specification of JB/T5897-2006 “Explosion Proof Overhead Crane”, and the explosion-proof grade covers ExdⅡBT4 and ExdⅡCT4, which is suitable for the operation scenario with the rated lifting capacity of 1-20 tons and span of 7.5-31.5 meters, and the working temperature ranges from -20℃ to +40℃.

LB explosion-proof single girder overhead travelling crane can be matched with many kinds of explosion-proof hoists, which are mainly selected according to the lifting capacity, explosion-proof class (IIB/IIC), and working condition (gas/dust explosion-proof). The common models are BCD, BMD, HB/HBS, of which:

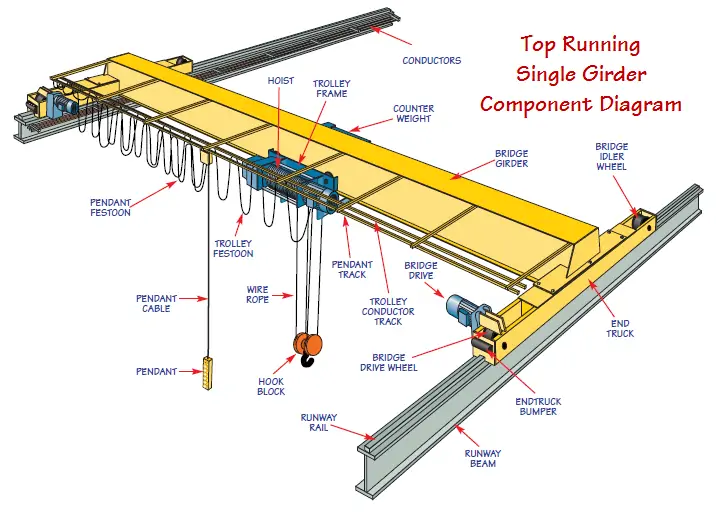

The structure of the LB type explosion-proof single girder overhead travelling crane mainly consists of four main parts: the large vehicle running mechanism, the small vehicle running mechanism, the lifting mechanism, and the electrical equipment.

LB type explosion-proof electric single girder overhead travelling crane is specially designed for flammable and explosive environments, and is suitable for dangerous places where explosive gas or dust mixtures exist. It is widely used in the military industry, arsenal, petroleum, petrochemical, coal mine, chemical industry, aviation, and other industries, and can safely and efficiently lift goods in workshops, warehouses, and other occasions. The travelling overhead crane is particularly suitable for handling flammable and explosive objects or gases, such as petroleum products, chemicals, natural gas, etc. It ensures that the lifting tasks are completed under strict safety standards, and it is an indispensable lifting equipment in hazardous environments.

| Span (m) | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 |

| Capacity (t) | 1~31.5t | ||||||

| Total weight (kg) | 1781~12086 | ||||||

| Trolley weight (kg) | 405~740 | ||||||

| Max. Wheel load (kn) | 13.5~90.94 | ||||||

| Travel rail | P24~P43 | ||||||

| Lifting speed (m/min) | 0.8/5 | 0.8/5 | 0.8/5 | 0.8/5 | 0.8/5 | 0.8/5 | 0.8/5 |

| Lifting height (m) | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 |

| Total motor power (kw) | 4.31 | 4.31 | 4.31 | 4.31 | 4.67 | 4.67 | 4.67 |

| Crane speed (m/min) | 3-30 | 3-30 | 3-30 | 3-30 | 3-30 | 3-30 | 3-30 |

| Trolley speed (m/min) | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 |

| Trabajo | M5/A5 | ||||||

No dude en dejarnos un mensaje. Le responderemos en 24 horas.

Enviar solicitud