Puentes grúa

The 20-ton overhead crane is a cost-effective lifting solution designed to easily move heavy loads. Designed to deliver exceptional durability, precision, and safety, it significantly improves productivity by reducing manual labor and the risk of accidents, ensuring smooth operation in demanding industrial environments.

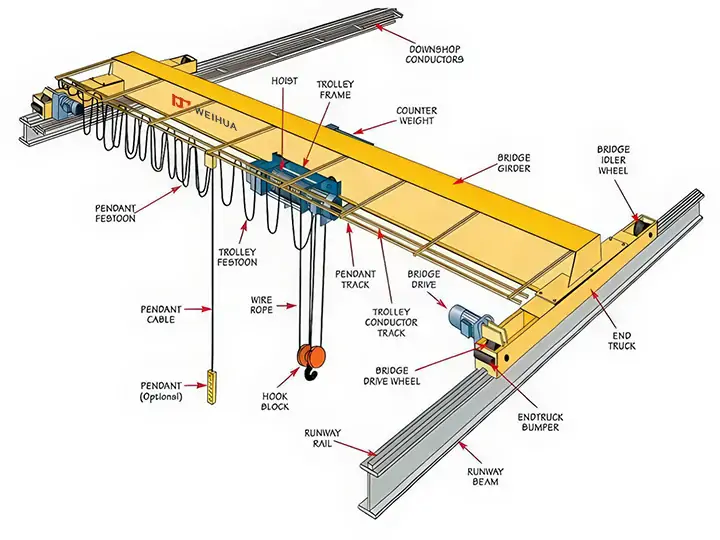

A single-girder overhead crane consists of a main girder, end beams, operating mechanism, and electric hoist.

20-ton single-girder bridge crane parts

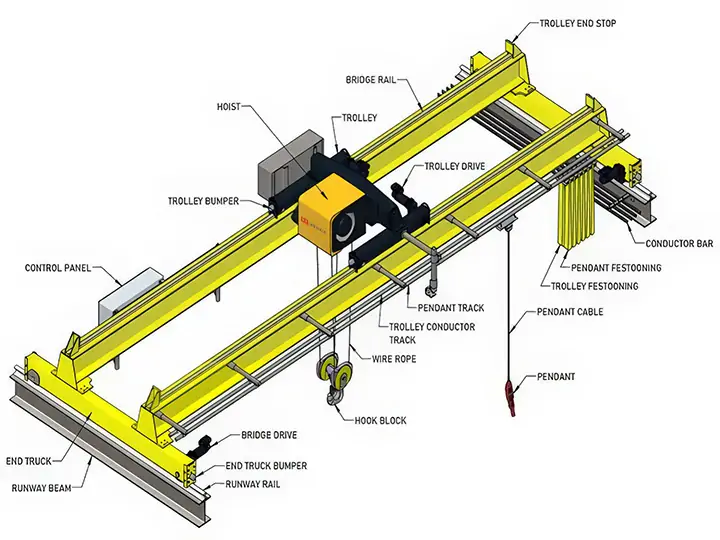

A double-girder overhead crane consists of a main beam, end beam, trolley running mechanism, bridge running mechanism, lifting mechanism, track, driver's cab, walking platform and other parts.

20-ton double-girder bridge crane parts

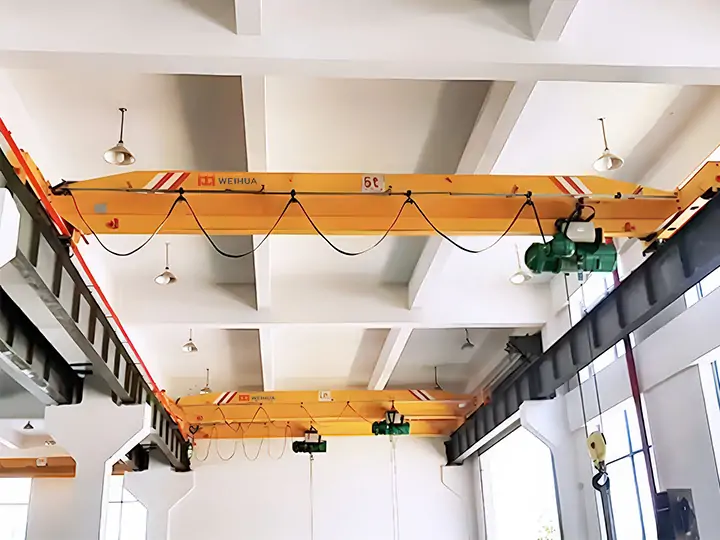

The LD 20 ton single girder overhead crane is a cost-effective single girder lifting solution for light to medium-duty applications. It is compact and easy to install, making it an ideal choice for workshops and warehouses requiring reliable, low-maintenance material handling.

LB Explosion-Proof Single Girder Overhead Traveling Crane

LB type 20 ton explosion-proof single girder overhead crane is specially designed for flammable and explosive environments. It has the explosion-proof mark of Ex and complies with GB3836.1-2000 and GB3836.2-2000 standards.

HD Type European Single Girder Bridge Crane

The HD European-style 20-ton single-girder overhead crane, equipped with a low-headroom electric hoist, delivers high performance in a compact space. Designed for smooth, energy-efficient operation, it's ideal for precision lifting in workshops and industrial plants.

Single Girder Grab Bucket EOT Crane

The 20-ton single-girder overhead crane with grab bucket offers a compact design for light to medium-duty applications. It's ideal for workshops, small warehouses, or other locations with limited space. Equipped with a grab bucket, it efficiently handles loose materials such as sand, grain, and fly ash.

QD Double Girder Hook Overhead Crane

The QD 20-ton double-girder overhead crane adopts a double-girder structure and uses a hook as a spreader to achieve precise lifting and horizontal movement. It has the characteristics of strong carrying capacity and strong flexibility, and is suitable for handling large or heavy objects.

QZ Grab Overhead Crane

The QZ 20-ton double-girder grab crane is a heavy-duty bulk material handling equipment featuring two parallel main beams that improve load-bearing capacity and operational stability. It is widely used in mining, metallurgy, cement, chemical industry and power plants.

Puente grúa europeo de dos vigas

The 20-ton European double-girder overhead crane is a material handling equipment that adopts advanced European design concepts and manufacturing standards. It features a compact structure, smooth operation, and variable frequency control. It is mainly used in production environments such as warehouses, workshops, and precision assembly.

The QC 20-ton electromagnetic overhead crane is a highly efficient material handling equipment equipped with removable electromagnets for handling and lifting metals. It is commonly used in steel mills, ports, scrap yards and other places where large quantities of ferromagnetic materials need to be lifted and handled.

The QY 20-ton insulated bridge crane is a type of lifting equipment used in specific industrial scenarios. It is mainly suitable for smelting workshops of non-ferrous metals such as electrolytic aluminum, magnesium, lead, and zinc.

The QB 20-ton explosion-proof double-girder bridge crane is a lifting equipment specially designed for flammable and explosive gas or dust environments. Its main components adopt explosion-proof structures and materials, and have high safety and reliability.

QDY Metallurgy Crane

The QDY 20-ton metallurgical crane is a heavy-duty lifting equipment designed for harsh environments such as high temperature and high dust. It is particularly suitable for handling molten metal, hot steel and other high-temperature materials. It is widely used in the steelmaking, casting and rolling industries.

The YZ 20-ton casting crane is a heavy-duty lifting equipment designed specifically for steel smelting workshops. It is mainly used for lifting, pouring, and stirring high-temperature liquid metal.

Overall, choosing a single-girder or double-girder 20-ton overhead crane depends on the specific needs of your business. If you need to lift heavier loads or span longer distances, a double-girder crane may be a better choice. If you are concerned about cost or require a lightweight crane, a single-girder crane may be a better choice.

20-ton overhead cranes offer many advantages that can help businesses improve efficiency, reduce costs, and enhance workplace safety. 20-ton overhead cranes are commonly used in a variety of industries requiring heavy lifting and material handling.

The price of a 20-ton overhead crane depends on several key factors, including crane type, design features, and additional services such as installation and maintenance.

Typical Price Range

Basic single-girder crane: Approximately $28,000 to $88,000 (Suitable for standard lifting operations.)

Advanced double-girder crane: Starting at $100,000 and above (Includes enhanced performance, durability, and special features.)

At Weihua Group, we specialize in providing customized lifting solutions to meet our customers' specific needs. We offer modular designs to meet diverse requirements while ensuring structural stability and standardized production.

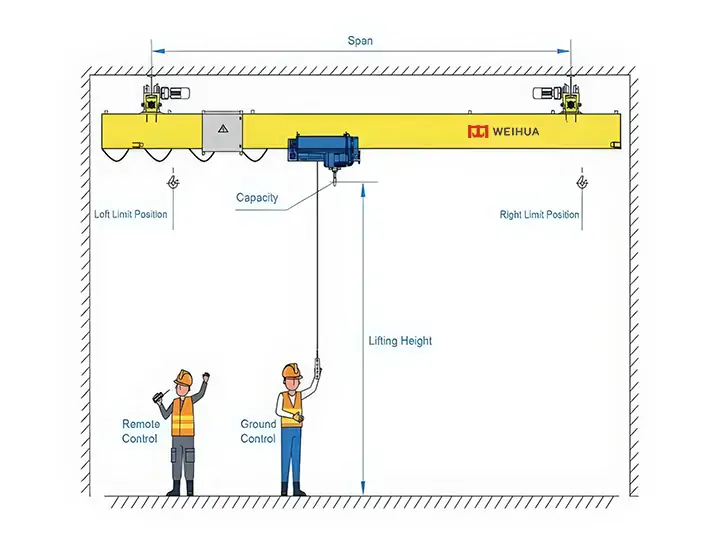

Lifting Capacity: 5-800 tons

Span: Adjustable to suit your facility (typically 10-50 meters)

Lift Height: Customizable (10-40 meters)

Control Options: Remote/Cab Control

Lift Speed: Customizable (0.8/8 m/min)

If you have any special requirements or need further assistance, please feel free to contact our expert team, who will provide customized solutions and professional support.

Consider factors such as load capacity, span length, lifting height, crane type, functionality, material, installation and maintenance, and any customization requirements. It's crucial to choose a reputable supplier or manufacturer who can provide professional guidance and advice.

Follow the manufacturer's recommended maintenance schedule and regularly inspect the crane's components. Keep the crane clean and lubricated, and promptly address any issues or repairs. Training employees on proper crane operation and safety procedures is also crucial.

Proper operator training, regular maintenance and inspections, ensuring proper load capacity and weight distribution, and adhering to all safety guidelines and regulations are crucial. It's also important to use appropriate personal protective equipment and maintain a safe distance from the crane during operation.

Refer to the manufacturer's manual for guidance on identifying and resolving issues. Common problems may include electrical and mechanical issues, as well as issues with the crane or trolley. Promptly resolving any issues is crucial to ensure safe and efficient crane operation.

The service life of a 20-ton overhead crane depends on factors such as usage, maintenance, and environmental conditions. With proper care and maintenance, a 20-ton overhead crane can provide many years of service.

Yes, a 20-ton overhead crane can be customized to meet specific business needs. This may include modifications to the load capacity, span length, lifting height, or crane functionality.

The lead time for a 20-ton overhead crane order can vary depending on factors such as crane type, customization requirements, and material availability. It is crucial to select a reputable supplier or manufacturer who can provide an accurate lead time estimate based on your specific needs.

No dude en dejarnos un mensaje. Le responderemos en 24 horas.

Enviar solicitud