Noticias del sector

Both quay crane and gantry crane are lifting equipment for outdoor heavy-duty work, widely used in modern harbor logistics and the industrial handling field. However, there are obvious differences between the two in terms of structural design, working principle, performance characteristics, and application scenarios. In this article, we will analyze the differences between Quay Crane Vs Gantry Crane to help you fully understand the characteristics and application scenarios of these two types of equipment, and provide you with a professional equipment selection reference. Please continue to read this article:

Quay cranes and gantry cranes have great differences in structural design. From the appearance, the shore bridge presents a towering “A” frame structure, while the gantry crane is shaped like a “door” frame, and its different structural form directly determines their respective application scenarios and functional characteristics.

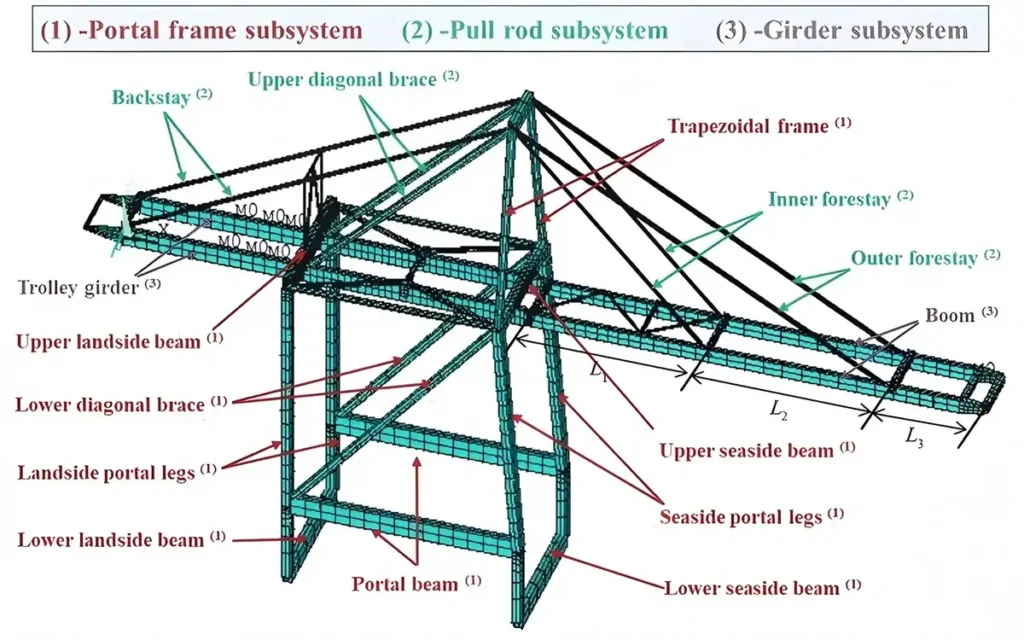

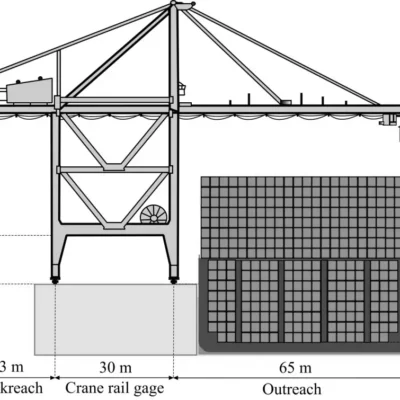

Quay cranes are special structures designed for container handling in ports. Supported by a tall door-shaped frame, the front end is equipped with a long cantilever that can be tilted (front reach), and the end of the cantilever is equipped with a container spreader. The metal structure of the quay bridge mainly consists of the front tie rods, rear tie rods, trapezoidal frames, door frames, and traveling mechanisms. Its height usually reaches 70-80 meters (equivalent to the height of more than 20 floors), in order to cross the deck of large container ships. The rear reach (the part that extends landward) of the quay bridge is designed to serve container trailers or automated guided vehicles (AGVs) at the front of the terminal.

The structure of the gantry crane consists of the main girder, outriggers, lower beams, and the large vehicle operating mechanism, forming a “gate” shaped frame. According to the form of gantry structure, gantry cranes can be divided into full gantry (main girder without overhang), semi-gantry (outriggers with height difference), double cantilever gantry and single cantilever gantry, and other types. According to the main girder form is divided into single main beam and double main beam structure, of which the single main beam structure is simple, light weight, suitable for lifting capacity ≤ 50t, span ≤ 35m occasions; while the double main beam has a strong load carrying capacity (up to 500 + ton), large span, but the weight and cost is higher.

Shore bridge cranes and gantry cranes walking mechanism is also very different. Shore bridges usually walk along the track laid along the front of the quay, and use a high-precision traveling mechanism of the big car to ensure stability during loading and unloading operations. While the walking mechanism of the gantry crane is more diverse, including rail type (for fixed workplaces), tire type (such as RTG, tire gantry crane, widely used in container yards), more widely used.

In terms of material selection for the load-bearing structure, the shore bridge mainly adopts a box structure welded with high-strength steel to ensure sufficient stiffness and wind resistance; gantry cranes, on the other hand, according to the different uses, can adopt a box girder, a truss girder, and other structural forms. Truss girder design has light deadweight, strong wind resistance, and low cost, and is commonly used in the field of bridging; box girder structure has strong lifting capacity, high safety, and high rigidity, and is suitable for frequent operations or outdoor operations with large lifting capacity.

| Structural Characteristics | Quay Crane | Grúas de pórtico |

|---|---|---|

| Overall form | Towering “A” frames | “Gate” shaped frame |

| Main beam form | Box-type structure is the main | Single/double main girder, box/truss/honeycomb girder |

| Cantilever design | Front reach + rear reach | Double cantilever, single cantilever or no cantilever available |

| Traveling Mechanism | Traveling on railcars | Rail or tire type (RTG) |

| Typical height | 70-80 meters | Typically 10-30 meters |

Quay crane and gantry crane have obvious differences in working principle due to their different design requirements and operating environment.

The working principle of the quay crane is mainly through the mechanical device and control system, the container will be unloaded from the ship or loaded onto the ship. The working process can be divided into three key steps: first of all, moving to the working position, the quay crane walks along the quay front track to the target container corresponding to the shell position; followed by rotary positioning, through the slewing mechanism will be lifting trolley to turn to the direction of the ship or yard; finally, lifting loading and unloading link, the trolley moves along the main beam, with the lifting mechanism to complete the container gripping and placing.

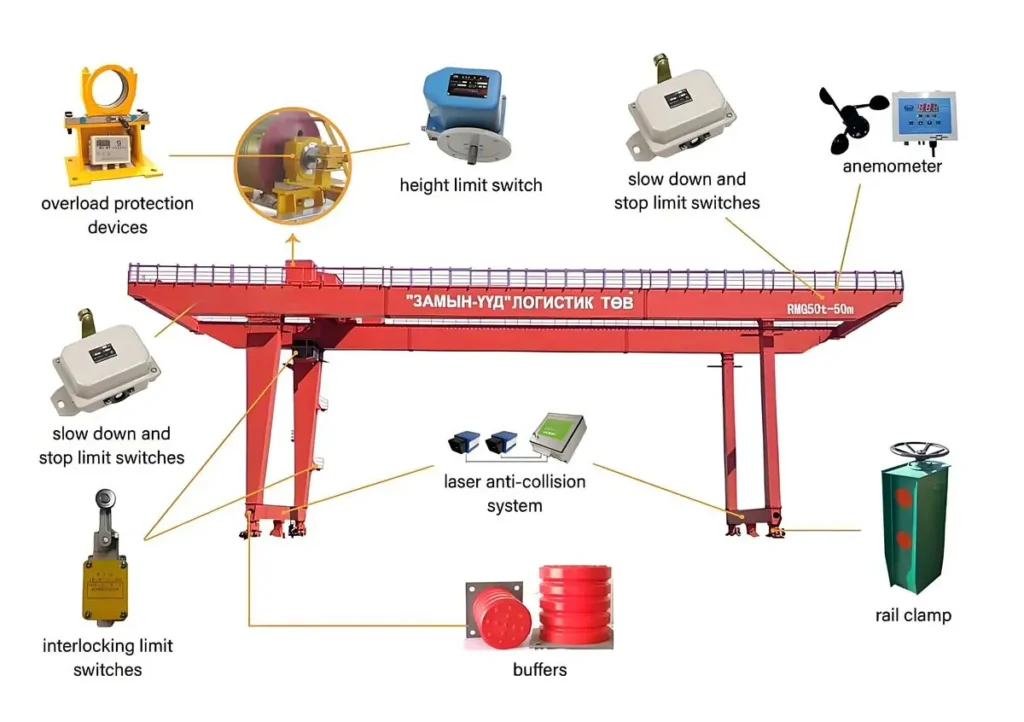

Gantry cranes are mainly used in material handling and stacking operations in cargo yards and stockyards. Its basic working principle is to realize material handling and transfer operations through the walking along the ground track, the movement of the trolley along the main beam, and the lifting mechanism of the lifting movement. The quay crane focuses on container loading and unloading, while the gantry crane can be equipped with hooks, grabs, electromagnetic suction cups and other spreaders according to the need to adapt to the handling of different materials.

| Working Characteristics | Quay Cranes | Grúas de pórtico |

|---|---|---|

| Core Functions | Container ship loading and unloading | Yard material handling and stacking |

| Operation mode | Anti-collision, wind speed monitoring, and limit protection | Driver's cab operation, intelligent development |

| Movement Characteristics | High speed operation, special pitching mechanism | Stable and precise, moderate speed |

| Spreader types | Specialized container spreader | Variety (hook, grab, electromagnetic, etc.) |

| Safety system | Anti-collision, wind speed monitoring, limit protection | Load protection, limit protection, anti-sway control |

According to their structural characteristics and working performance, quay cranes and gantry cranes are used in different application scenarios. Quay cranes are concentrated in modern container terminals, where the loading and unloading of container ships is carried out at the front of the terminal, where the containers are unloaded from the ships to the terminal transportation equipment (e.g., straddle carriers, AGVs, or trailers) or are loaded in the reverse direction.

Gantry cranes have a much wider range of applications and can be used in all industrial fields that require heavy material handling. Depending on the type, gantry cranes are mainly used in the following major scenarios:

Through the above comprehensive comparative analysis of Quay Crane and Gantry Crane, we can see that there are significant differences between these two types of lifting equipment in terms of structural design, working principle, performance characteristics, and application scenarios. As the professional loading and unloading equipment at the front of the container terminal, the quay bridge has become the core equipment of modern ports with its high efficiency, high automation and specialization characteristics; while the gantry crane, with its versatility, site adaptability and flexible configuration advantages, plays an irreplaceable role in yard operations, industrial production and many other fields.

When selecting equipment, it is recommended that enterprises start from the actual demand, taking into account the site conditions, efficiency requirements and budget, and other factors. If you need more specific selection advice or personalized lifting solutions, please contact Weihua professional team. Our technical experts will provide you with a full range of professional consulting services, including equipment configuration, site planning, automation upgrades, etc., according to your actual working conditions, and customize the most cost-effective lifting equipment solutions for you.

Date:

Enviar solicitud