Port Cranes

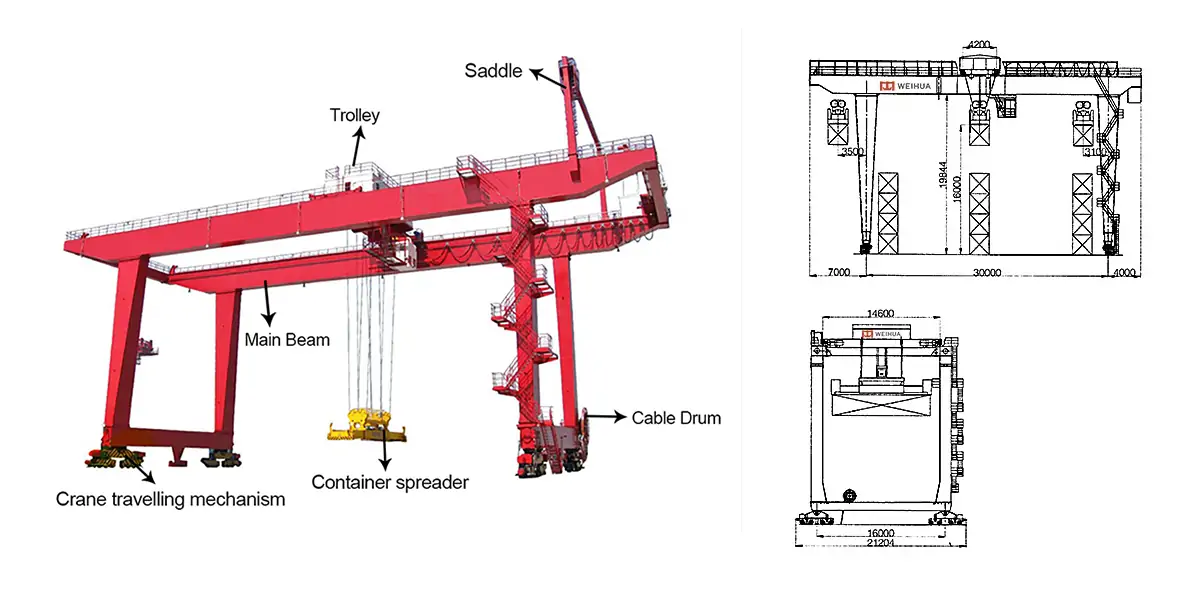

The rail mounted gantry crane is applicable to remove, load, and unload international standard containers. It is a highly efficient loading and unloading equipment, mainly for in ports, docks, and inland container yards. The main function is stacking, handling, and transshipment of containers from ships to land transport. The main beam is the core structure that bears the weight of the container. It is usually a box-shaped section to ensure strength. Its outriggers connect to both ends of the main beam. Thus, it could support the entire RMG crane and allow it to move along tracks on the ground.

The electric drive adopts the unique technology of full digital AC frequency conversion and PLC speed regulation control with flexible control and high precision. Standard bought-in components from well-known brands at home and abroad ensure overall quality.

The design, manufacture, and inspection comply with Chinese standards and international standards such as FEM, DIN, IEC, AWS, etc. Weihua’s RMG has the characteristics of multiple functions, stability, reliability, a wide range of operation, easy operation, and maintenance.

Our main products include RMG for railways: upper rotating (trolley rotation), lower rotating (spreader rotation), cantilevered, and non-cantilevered.

Rail mounted gantry crane mainly consists of a metal structure (main beam, outrigger, traveling cart), hoisting mechanism, trolley running mechanism, trolley running mechanism, electrical control system, and safety protection devices.

| Cpapcity of Spreader | Ton | 30.5 | 35 | 40.5 | 50 | ||

| Working Duty | A6 | A6 | A6 | A6 | |||

| Span(m) | Meter | 35 | 35 | 35 | 35 | ||

| Base(m) | Meter | 16 | 16 | 16 | 16 | ||

| Lifting Height (m) | Meter | 15.4 | 15.4 | 18.3 | 18.3 | ||

| Speed | Hoisting | With Full Load | m/min | 12 | 12 | 18 | 18 |

| Max. working Lcad of Wheel | 24 | 24 | 36 | 36 | |||

| Trolley Tavelling | 60 | 60 | 70 | 70 | |||

| Gantry Traveling | 45 | 45 | 45 | 45 | |||

| Total Power | kW | ~200 | ~230 | -255 | ~300 | ||

| Max. working load of Wheel | kN | 260 | 260 | 280 | 300 | ||

| Crane Rail | P50 | P50 | P50 | QU80 | |||

| Power Supply | 3-phase AC 50Hz 380V | ||||||

| Lifting capacity | Span range | Price range ($) |

|---|---|---|

| 30 ton rail-mounted gantry crane | 22m-30m | 250,000 - 320,000 |

| 50 ton rail-mounted gantry crane | 22m-32m | 400,000 - 460,000 |

| 60 ton rail mounted gantry crane | 22m-32m | 500,000 - 660,000 |

Please feel free to leave a message. We will reply in 24 hours.

Submit Request