Gantry Cranes

The 20-ton gantry crane is a highly efficient material handling equipment, named for its sturdy portal structure. It primarily consists of a metal structure, hoisting mechanism, trolley mechanism, and electrical control system. Its strong load-bearing capacity makes it suitable for heavy-load handling and lifting operations in various open-air locations, making it a valuable tool in warehousing, logistics, and construction.

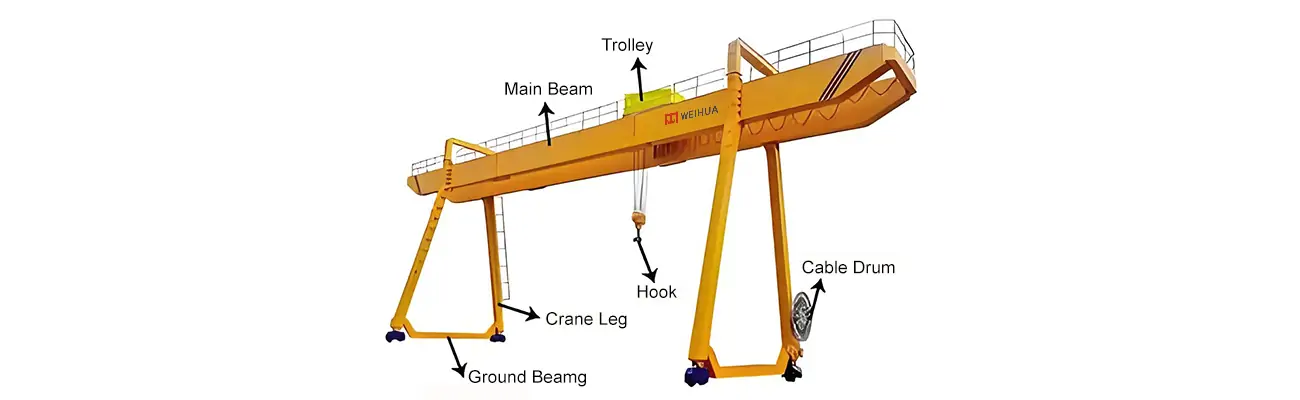

Main beam: Also known as the main girder, it supports the crane and load within the span. Main beams come in single-beam and double-beam types.

Outriggers: The supporting frame that connects the main beam to the ground and supports vertical loads. Designed as a box, A-shaped, or U-shaped frame, it can be fixed or equipped with wheels for mobility.

Hoisting mechanism: Raises and lowers the load. Available with CD/MD wire rope hoists, European hoists, or electric trolleys; single-speed, dual-speed, or variable-speed operation.

End wheels: Enable the crane to move along tracks or on the site. They utilize forged or cast steel wheels and are equipped with buffers and anti-derailment devices to ensure safe outdoor operation.

Crane operating mechanism: Drives the entire crane horizontally along tracks or on the ground. It includes the motor, reducer, and braking system. Designed for outdoor operation, it is dust- and water-resistant.

Electrical system: Controls lifting and traveling operations. Includes a control panel, power cables, and braking system.

Floor rails or rubber tires: Support the crane's movement on the ground. Ground rail: suitable for fixed track. Rubber tire: no need for track, flexible movement.

According to different structural designs and application scenarios, 20-ton gantry cranes are mainly divided into the following types:

L-type electric hoist gantry cranes are named for the "L" shape between the ground beam and the outriggers. They are usually used in conjunction with a trolley or wire rope electric hoist. They feature good leg clearance, short production cycles, high site utilization, and strong versatility.

Compact Structure, Stable Performance: The L-shaped electric hoist gantry crane features a box-type gantry structure, enabling easy installation, efficient operation, and adaptability to a variety of operating environments.

Large Lifting Space, Strong Span Capacity: The main beam utilizes a single-beam offset track design, facilitating transfer of loads from span to under the boom.

Multiple Safety Protections: Overload and undervoltage protection, droop control, and remote operation are all included. The enclosed cab features tempered glass and an insulated floor, ensuring safe operation.

Durable, Reliable, and Easy-Maintenance: Constructed of high-quality steel, it offers strong wind resistance, low failure rates, a long service life, and low maintenance costs.

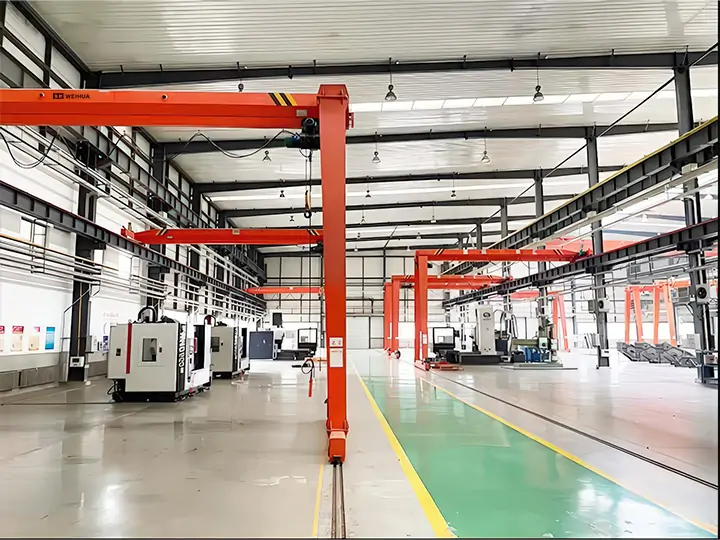

The 20-ton single-girder hoist gantry crane is a common lightweight lifting device, particularly suitable for cargo loading and unloading operations in warehouses, factories, docks, and other locations. It primarily consists of a bridge (including a main girder and end beams), an electric hoist, a trolley mechanism, and an electrical control system. This gantry crane with a hoist is popular among users for its compact structure, ease of operation, and small footprint.

Simple Structure: Utilizing a box-type or I-beam structure, this model features a rational design, is lightweight, and is easy to install and maintain.

Flexible Operation: Supports ground-level operation and offers smooth operation, making it suitable for various locations, such as factories, warehouses, and freight yards.

High Cost-Effective: Its relatively low manufacturing cost makes it an economical and practical choice for small and medium-tonnage lifting needs.

Compatible with a variety of electric hoists: Compatible with a variety of electric hoists, including CD, MD, and European hoists, to meet the needs of diverse working conditions.

The BMH single-girder semi-gantry crane is a lightweight rail-mounted gantry crane suitable for use with electric hoists such as the CD1, MD, and HC models. With a lifting capacity range of 2-20 tons and a span of 6-20 meters, it operates in temperatures ranging from -20°C to +40°C and is widely used for lifting cargo in public spaces such as factories, warehouses, and freight yards.

Wide Applicability: Suitable for a variety of complex environments, including high-temperature and explosion-proof environments, meeting diverse industrial needs.

Scientific Structure and Strong Rigidity: Robust construction, easy installation, and simplified maintenance reduce operating costs.

Variable Frequency Drive for Stable Operation: Equipped with a variable frequency control system, it achieves stepless speed regulation for smooth and precise operation.

Flexible Control: Supports cockpit and remote control for convenient operation, improving work efficiency and safety.

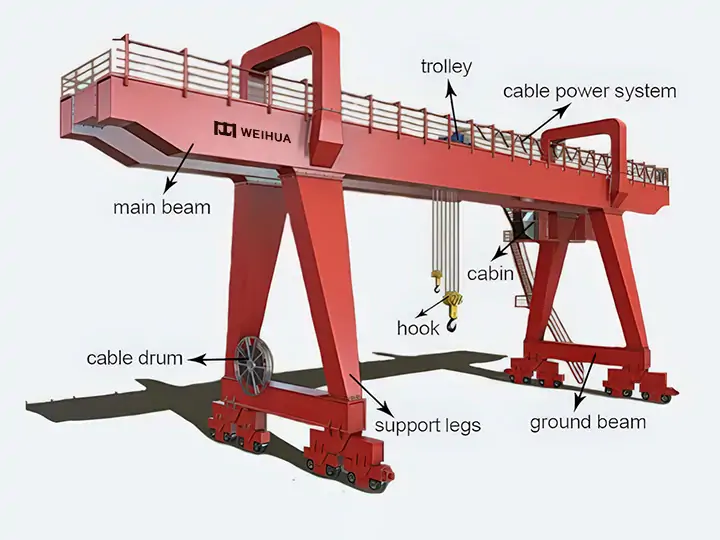

European-style double-girder gantry cranes adopt European standards, feature hardened gear reducers, a three-in-one drive system, and PLC+frequency conversion control technology, comprehensively enhancing product performance. They are suitable for general handling and lifting operations in open warehouses or along railway lines, and can also be equipped with a variety of lifting equipment for specialized operations.

Lightweight, Low Wheel Pressure Design: Utilizing high-strength steel and an optimized structure, the machine boasts a lightweight design and low wheel pressure, reducing track and construction investment costs.

Reduced Maintenance, Cost Savings: Key components utilize high-quality components that meet European standards (FEM/DIN), reducing failure rates and repair frequency, and saving over 30% in overall operating costs.

Space-Optimized Design: The low headroom structure increases the effective lifting height, making it particularly suitable for locations with height restrictions and maximizing factory space utilization.

The U-shaped outdoor double-girder gantry crane is primarily used for general loading and unloading and lifting operations. Its increased trolley gauge provides greater legroom, making it suitable for handling larger objects such as containers. Due to its structural design, this type of gantry crane does not require a saddle frame, unlike an A-shaped gantry crane.

Unique U-shaped frame: The stable "U" structure provides excellent bending and torsional rigidity, enhancing overall stability.

Efficient control system: Quick response and smooth operation improve work efficiency and operational precision.

Large-span coverage: Spanning multiple tracks or work areas, increasing operational flexibility and adapting to complex and changing working environments.

A portable gantry crane is a mobile lifting device. It requires no fixed foundation and can be quickly installed and removed. Its compact design maximizes floor space utilization. It is suitable for various scenarios, including temporary lifting tasks, workshop handling, and outdoor operations.

Lightweight and Portable: Made of aluminum alloy, it's lightweight and easy to carry and move. Compared to traditional steel equipment, it's more flexible and can be easily transferred between locations.

Portable Design: Folds up when not in use, saving space for transport and storage.

Adjustable Height and Span: The height and span can be flexibly adjusted to suit different work scenarios.

A truss gantry crane is a type of gantry crane that uses a truss structure as the main beam. The rigid or flexible legs on both sides and the top truss main beam form a portal frame. The gantry crane can move along the ground track to perform lifting operations. It is particularly suitable for windy places such as ports and coastal areas.

Lightweight Design: Utilizing a spatial truss structure, it is lightweight and requires minimal foundation load, making it suitable for large-span operations.

Excellent Wind Resistance: The open truss structure offers low wind resistance, excellent air permeability, and excellent stability, making it particularly suitable for operations in open-air environments such as ports and wind turbine installations. Its stability is superior to that of box cranes in high-wind speed areas.

Highly Economical: Low material consumption and manufacturing costs make it particularly suitable for small and medium-sized tonnage applications. The lightweight design also reduces investment in supporting equipment (such as tracks and motors).

Types | Rated lifting capacity | span | Lifting height | Job Level | Trolley running speed | Crane running speed | Power supply mode |

|---|---|---|---|---|---|---|---|

L-Type Gantry Crane With Electric Hoist | 20 ton | 18-35m | 10-11m | A5 | 39.3m/min | 40.1-47.1m/min | Three-phase AC, 380 V , 50 Hz |

MH Single Beam Hoist Gantry Crane | 20 ton | 12-35m | 6-12m | A5 | 20m/min | 20-30m/min | Three-phase AC, 380 V , 50 Hz |

BMH Single Girder Semi Gantry Crane | 20 ton | 6-20m | 6-12m | A4 | 20-30m/min | 20-30m/min | Three-phase AC, 380 V , 50 Hz |

European Double Beam Gantry Crane | 20 ton | 18-35m | 10-12m | A5 | 3.2-32m/min | 4.0-40m/min | Three-phase AC, 380 V , 50 Hz |

U-Type Double Girder Outdoor Gantry Crane | 20 ton | 18-35m | 10-10.5m | A5 | 44.6m/min | 44m/min | Three-phase AC, 380 V , 50 Hz |

Portable Gantry Crane | 20 ton | 12-30m | 6.0-9m | A5 | 10-20m/min | 15-30m/min | Three-phase AC, 380 V , 50 Hz |

MH Truss Single Girder Gantry Crane | 20 ton | 7.5-31.5m | 6-24m | A5 | 3-8m/min | 20-30m/min | Three-phase AC, 380 V , 50 Hz |

1. Construction: 20-ton gantry cranes are used to lift steel beams, concrete blocks, and prefabricated components on large construction sites.

2. Shipbuilding: In shipyards, 20-ton gantry cranes move heavy components such as engines, ship hulls, and steel plates.

3. Warehousing: 20-ton gantry cranes simplify the loading and unloading of large cargo, improving warehouse logistics.

4. Railway freight yards: They assist in the high-precision lifting of railway components and containers.

5. Steel and fabrication plants: 20-ton gantry cranes are essential for handling raw materials and finished products such as coils, billets, and prefabricated structures.

6. Power plants: They are used to position turbines, generators, and transformers.

Weihua Crane is dedicated to providing customized lifting solutions to meet the diverse needs of our customers. We offer modular designs to meet diverse requirements while ensuring structural stability and standardized production.

Lifting Capacity: 20 tons (customizable)

Span: Customizable

Lift Height: Customizable

Control Options: Pendant/Remote Control

Hoist Type: Electric Wire Rope Hoist, Electric Chain Hoist, or Explosion-Proof Hoist

Certifications: CE, ISO, EAC, etc.

Job Duties: A3-A5

If you have any specific needs or require further assistance, please contact our expert team and share your requirements. We will be happy to provide you with customized solutions and professional support.

Please feel free to leave a message. We will reply in 24 hours.

Submit Request