Industry News

Overhead cranes are an efficient material handling solution that plays a vital role in industrial production. When purchasing overhead cranes, price is usually the primary concern for customers. However, a combination of factors such as tonnage, structure, certifications, transportation, and maintenance means that a seemingly simple quote hides a complex cost structure. This article will introduce the main types of overhead cranes and detail the key factors affecting their price, helping you make the right investment decision.

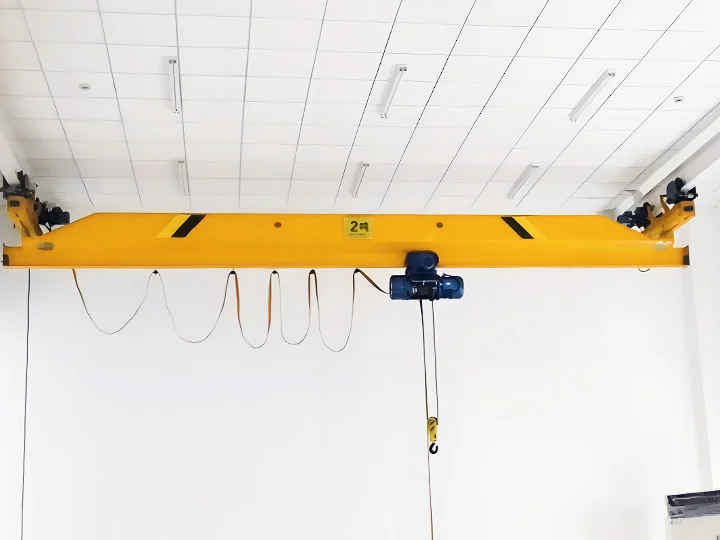

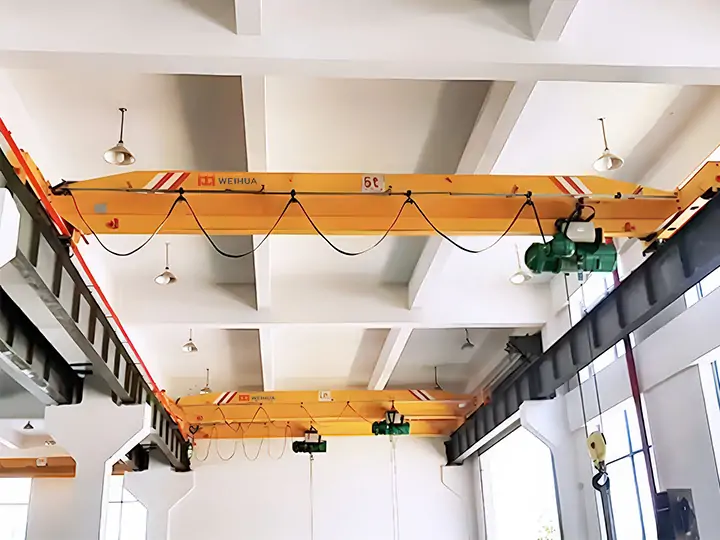

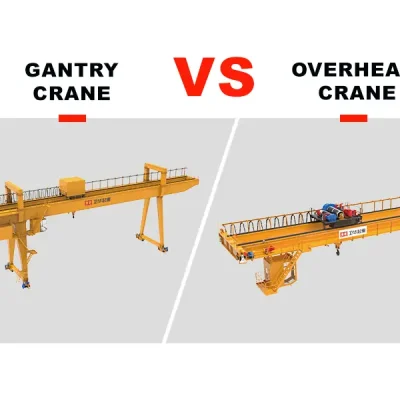

An overhead crane is a type of lifting equipment widely used above workshops, warehouses, and material storage yards, primarily for lifting materials. Its structural feature is that it spans across the work area, with both ends built on concrete columns or steel structures, resembling a bridge in shape, hence the common names "bridge crane" or "elevated crane." Based on the design of the main beam, it can be divided into single-girder overhead cranes and double-girder overhead cranes. Please continue reading:

LD Type Single Girder EOT Crane

Suspension Underhung Overhead Crane

LB Explosion-Proof Single Girder Overhead Traveling Crane

Single Girder Double Hoist Overhead Crane

HD Type European Single Girder Bridge Crane

Single Girder Grab Bucket EOT Crane

| Single Girder Overhead Crane | Span(m) | Lifting Height(m) | Price(USD) |

| 1 ton | 7.5~31.5 | 6~30 | $2200~40000 |

| 2 ton | 7.5~31.5 | 6~30 | $2500~40800 |

| 3 ton | 7.5~31.5 | 6~30 | $2600~41000 |

| 5 ton | 7.5~31.5 | 6~30 | $3000~41500 |

| 10 ton | 7.5~31.5 | 6~30 | $4000~45000 |

| 16 ton | 7.5~31.5 | 6~30 | $5000~48000 |

| 20 ton | 7.5~31.5 | 6~30 | $6000~50000 |

| 25 ton | 7.5~31.5 | 6~30 | $8000~56000 |

Notice: The above prices are for reference only. The specific prices are subject to the actual specifications.

QZ Grab Overhead Crane

European Double Girder Bridge Crane

QC Electromagnetic Overhead Crane

QY Type Insulation Hook Bridge Crane

QDY Metallurgy Crane

YZ Type Steel Foundry Crane

QB Explosion Proof Overhead Crane

QD Double Girder Hook Overhead Crane

| Double Girder Overhead Crane | Span(m) | Lifting Height(m) | Price(USD) |

| 1 ton | 7.5~31.5 | 6~30 | $4000-60000 |

| 2 ton | 7.5~31.5 | 6~30 | $4500-62000 |

| 3 ton | 7.5~31.5 | 6~30 | $5000-66000 |

| 5 ton | 7.5~31.5 | 6~30 | $5800-72000 |

| 10 ton | 7.5~31.5 | 6~30 | $6500-79000 |

| 16 ton | 7.5~31.5 | 6~30 | $7800-86000 |

| 20 ton | 7.5~31.5 | 6~30 | $8600-95000 |

| 25 ton | 7.5~31.5 | 6~30 | $9800-110000 |

Notice: The above prices are for reference only. The specific prices are subject to the actual specifications.

The prices listed above are only the initial purchase price. The cost of a bridge crane covers all investments required throughout its entire lifecycle, including acquisition, transportation, installation, maintenance, and operation.

The initial price of a bridge crane is influenced by several factors, including:

Transportation costs represent a significant portion of the total investment, especially for large, custom-built bridge cranes. These costs include:

Distance from the manufacturer: The greater the distance, the higher the freight costs. International freight may also incur additional charges such as customs duties, port fees, and taxes.

Size and weight of crane components: Heavier or oversized components require specialized transportation methods, such as flatbed trucks, modular trailers, or containers.

Transportation methods: Options include road, rail, sea, or air freight. Air freight is faster but significantly more expensive than sea freight.

Structural Modification: Reinforcing or extending the building to support the crane.

Labor Costs: Hiring certified professionals for crane assembly, calibration, and installation.

Testing and Commissioning: Ensuring the crane meets operational and safety standards.

Energy Consumption: Energy costs can vary significantly depending on the crane's capacity and frequency of use.

Operator Training: Skilled operators are crucial for the safe and efficient use of the crane. Training programs and certifications can be an ongoing expense.

Inspection: Regular inspections according to safety standards to detect wear and tear.

Parts Replacement: Components such as motors, cables, and brakes require regular replacement.

Lubrication and Cleaning: Ensuring smooth operation and extending the crane's lifespan.

Downtime: Costs incurred due to downtime for repairs or maintenance.

When purchasing a bridge crane, the total cost should be considered in addition to the initial purchase price. While the lower initial price may seem attractive, cranes equipped with higher quality components, more energy-efficient models, and more reliable performance can reduce long-term costs and improve operational efficiency.

To summarize, the price of overhead cranes is affected by many factors such as tonnage, span, driving mode, brand positioning, additional features, etc. The price range varies from several thousand to hundreds of thousands of US dollars. It is recommended that when you are shopping for a bridge crane, you compare the technical solutions and full-cycle costs of 3-5 overhead crane suppliers for a comprehensive evaluation, taking into account the actual working conditions and frequency of use. If you need a specific bridge crane quotation, please contact Weihua's professional team to provide load calculation, program selection, quotation, etc.

Date:

Submit Request