Ponts roulants

When you're looking for high-quality overhead cranes, Groupe Weihua offers a wide range of types and prices to suit your needs. We are committed to providing lifting equipment that excels in load capacity, safety, and operational efficiency. At Weihua Crane, you can find the perfect overhead crane to meet your project needs.

The 10-ton overhead crane is a type of lifting equipment widely used in machinery manufacturing, warehouse management, material yard loading and unloading and other fields. It has a reasonable structural design and strong rigidity of the whole machine. It has the advantages of superior performance, safety and reliability, energy saving and high efficiency, low noise, and environmental protection, which can ensure the stability and safety of lifting operations.

A bridge crane primarily consists of a main girder, end beams, hoisting mechanism, crane operating mechanism, control system, and electrical equipment.Designing various components can enhance the crane's lifting capacity and performance.

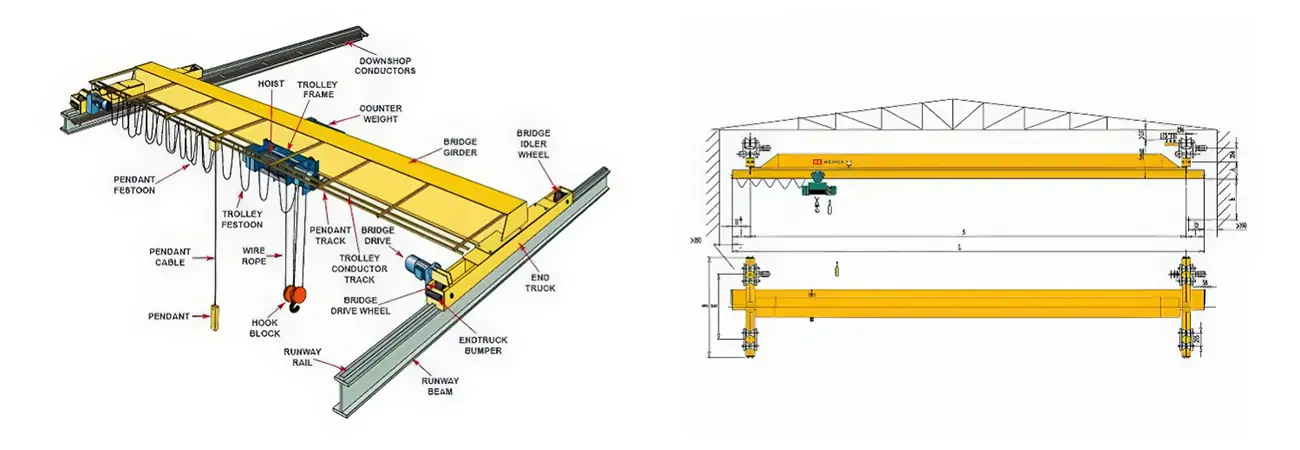

Single-girder bridge crane parts

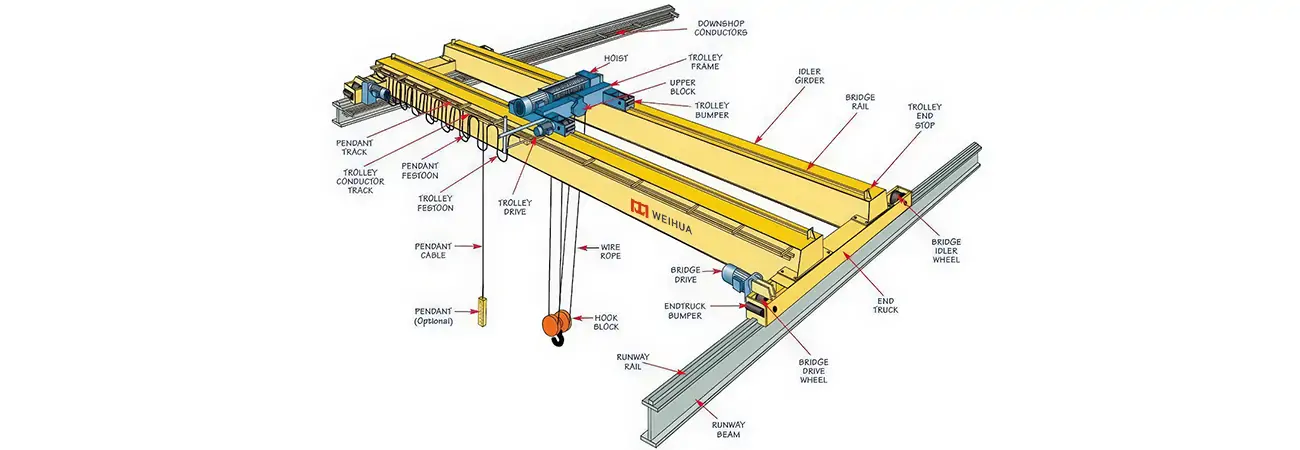

Double-girder bridge crane parts

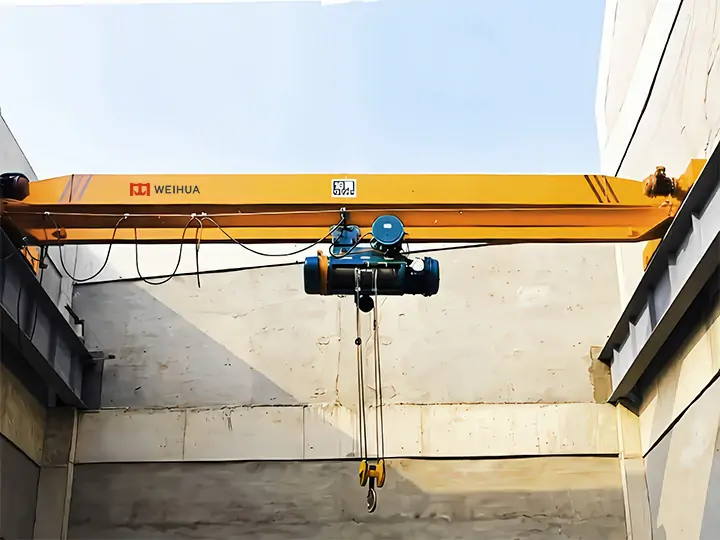

The LD single-girder eot crane (E-Bridge Crane) is designed to provide an efficient lifting solution for light and medium-duty applications. It utilizes a single girder as the bridge's main beam and features a trolley that moves along the beam to lift the load. Driven by an electric motor system, it delivers smooth and precise lifting operations.

Its compact design makes it suitable for environments with limited headroom or space constraints, such as factories, workshops, and warehouses. It is ideal for lifting small and medium-sized loads efficiently and at low operating costs.

LD Type Single Girder EOT Crane

Specifications

| Capacité de levage | 1 ton | 2 ton | 3 ton | 5 ton | 10 ton | 16 ton | 20 ton |

| La portée | 7.5-31.5 m | ||||||

| Hauteur de levage | 6, 9, 12 m | ||||||

| Vitesse de levage | 8(8/0.8) m/min | 7(7/0.7) m/min | 3.5(0.35/3.5) m/min | 3.3(0.33/3.3) m/min | |||

| Vitesse de déplacement du palan | 20 m/min | ||||||

| Vitesse de déplacement de la grue | 20(30) m/min | ||||||

| Working Level | A3, A4, A5 | ||||||

| Puissance | Trois phrases ; 380V, 50Hz | ||||||

Underhung overhead cranes are efficient and flexible lifting equipment designed to meet the lifting needs of modern industrial production. Featuring an advanced suspension design and paired with an electric hoist, these cranes can lift, move, and lower objects. This allows them to operate in relatively low spaces, optimizing space utilization and improving production efficiency.

Specifications

| Conditions | Unité | Ampleur |

| Capacité de chargement | tonne | 0.5~10 |

| La portée | compteur | 3~22.5 |

| Vitesse de déplacement de la grue | m/min | 20m/min |

| Vitesse de levage | m/min | 7~8, 0.7~0.8/7~8 |

| Vitesse de déplacement du chariot | m/min | 20m/min |

| Grade de travail | -- | A3 |

| Alimentation électrique | -- | 3ph, 380V, 50Hz ou sur mesure |

LB Explosion-Proof Single Girder Overhead Traveling Crane is a lifting device designed for industrial environments requiring explosion-proof performance. It features a single-girder bridge structure, with the main and end beams constructed of high-strength steel, connected through precision welding and assembly processes.The crane's electrical control system has comprehensive safety features, including limit switches and overload protection, to ensure safe operation.

Specifications

| Span (m) | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 |

| Capacity (t) | 1~31.5t | ||||||

| Total weight (kg) | 1781~12086 | ||||||

| Trolley weight (kg) | 405~740 | ||||||

| Max. Wheel load (kn) | 13.5~90.94 | ||||||

| Travel rail | P24~P43 | ||||||

| Lifting speed (m/min) | 0.8/5 | 0.8/5 | 0.8/5 | 0.8/5 | 0.8/5 | 0.8/5 | 0.8/5 |

| Lifting height (m) | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 | ≥ 6 |

| Total motor power (kw) | 4.31 | 4.31 | 4.31 | 4.31 | 4.67 | 4.67 | 4.67 |

| Crane speed (m/min) | 3-30 | 3-30 | 3-30 | 3-30 | 3-30 | 3-30 | 3-30 |

| Trolley speed (m/min) | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 | 2-20 |

| Obligation de travail | M5/A5 | ||||||

Single-girder double-hoist overhead cranes utilize a box girder or I-beam as the primary load-bearing structure, with two electric hoists (typically wire rope hoists or chain hoists) mounted on the same main girder. Load capacities typically range from 5 to 20 tons (single hoist) or 10 to 32 tons (double hoist combined), with spans ranging from 5 to 22 meters. Their simple structure reduces manufacturing and maintenance costs compared to double-girder cranes. Their light weight makes them suitable for applications with height restrictions or limited load-bearing capacity.

Single Girder Double Hoist Overhead Crane

Specifications

| Modèle | LH Type Double Hoist Overhead Crane | ||||

| Capacité (tonne) | 5 | 10 | 16/3 | 20/5 | 32/5 |

| Portée (m) | 10.5-31.5 | ||||

| Hauteur de levage (m) | 6/9/12/18/Autre hauteur | ||||

| Vitesse de déplacement du chariot (m/min) | 20 | ||||

| Modèle de palan électrique | CD1(MD1) | ||||

| Vitesse de déplacement de la cabine (m/min) | 20 | ||||

| Vitesse de déplacement de la grue - Commande au sol (m/min) | 20 | ||||

| Classe ouvrière (FEM/ISO) | A3/A4 | ||||

| Source d'énergie | 3 phases A.C.50HZ 380V | ||||

The QD double-girder hook overhead crane is a heavy-duty industrial crane featuring a dual-girder structure and a hook as a spreader, enabling precise lifting and horizontal movement. Compared to a single-girder crane, the double-girder design offers greater stability and load-bearing capacity, making it suitable for handling large or heavy objects. It is widely used for lifting and handling materials in factories, warehouses, steel mills, hydropower stations, and other locations.

Specifications

| Modèle | Type QD | |||||||||

| Capacité de levage | t | 5 | 10 | 16/3.2 | 20/5 | 32/5 | 50/10 | 75/20 | 100/20 | |

| Hauteur de levage max. | Levage principal | m | 16 | 16 | 16 | 12 | 16 | 12 | 20 | 22 |

| Max. lifting height | m | 18 | 14 | 18 | 16 | 22 | 22 | |||

| La portée | m | 10.5-31.5 | 13.5-31.5 | 13-31 | ||||||

| Vitesse de levage | Principal | m/min | 11.3 | 8.5 | 7.9 | 7.2 | 7.5 | 5.9 | 6.1 | 3.9 |

| 15.6 | 10.4 | 10.7 | 9.8 | 9.5 | 7.8 | 6.1 | 4.9 | |||

| Aux. | 14.6 | 15.5 | 15.5 | 10.4 | 7.2 | 7.2 | ||||

| Vitesse de déplacement du chariot | m/min | 37.2 | 37.2 | 40.0 | 40.0 | 42.6 | 38.5 | 38.4 | 33.90 | |

| Vitesse de déplacement de la grue | A5 | m/min | 68.3/70.4 | 70.4/71.8/73.4 | 70/72/72.8 | 70/72/73 | 74.2/75.1 | 75/75/72 | 53.9 | 61.7 |

| A6 | 68.3/71.1/88.9 | 71.1/74.2/74.2 | 70/72/73 | 71.3/73.6/73.6 | 75 | 75/75/74 | 77.8/67 | 61.8 | ||

| Alimentation électrique | 3 Phrase A.C. 50Hz 380V ou autres | |||||||||

The QZ grab overhead crane is a general-purpose bridge crane designed specifically for bulk material handling. It combines the gripping capacity of a grab bucket with the maneuverability of a bridge crane, enabling efficient lifting operations in a variety of industrial environments.

This crane primarily consists of a bridge, hoisting mechanism, electrical control system, and grab bucket. It is primarily used for grabbing, transporting, stacking, and sorting various solid waste types, such as domestic waste, industrial waste, and construction waste.

Specifications

| Capacité de levage (t) | 5 | 10 | 16 | 20 | |

| Portée (m) | 10.5-31.5 | 16.5-31.5 | |||

| Hauteur de levage (m) | 20 | 18 | 28 | 26 | |

| Classe ouvrière | A6 | ||||

| Vitesse (m/min) | Levage par palan | 39.2 | 40.7 | 41.8 | 48.6 |

| Trolley en déplacement | 44.6 | 45.9 | 38.0 | 37.8 | |

| Déplacements de grues | 93.6/113.6 | 112.5/101 | 88/87.3 | 87.3 | |

| Alimentation électrique | 380V, 50HZ, 3 phases ou autres | ||||

The European double-girder overhead crane is a type of bridge crane designed using advanced European design concepts and manufacturing standards. It features a compact structure, light weight, smooth operation, and high energy efficiency. It is widely used for handling medium and heavy materials in factories, warehouses, power plants, ports, and other locations. Compared to traditional bridge cranes, the European double-girder bridge crane boasts a more advanced design, smaller size, and lighter weight.

Specifications

| Nom du produit | QDXX type Pont roulant |

| Capuchon | 3~100 tonnes, sur mesure |

| La portée | 4,5~31,5 mètres, sur mesure |

| Hauteur de levage | 3~30 mètres, sur mesure |

| Matériel de levage | Chariot électrique européen |

| Obligation de travail | A5-A8 |

| Puissance | Sur mesure |

| Température | -20℃~40℃ |

| Taux d'utilisation de l'espace | 90% |

| Pression des roues | 10-50KN |

| Fonctionnement de la vie | >30 ans |

| Pression atmosphérique | Pression atmosphérique standard |

QC electromagnetic overhead crane is a double-girder crane equipped with a removable electromagnetic lifting magnet. It utilizes electromagnetic force to lift metal materials. Electromagnetic coils generate magnetic force to secure the workpiece, which is then lifted using the crane's hoisting mechanism. The QC electromagnetic overhead crane offers advantages such as strong magnetic attraction, efficient handling, and adaptability to harsh environments. It is an ideal choice for industries such as steel, machinery, ports, and scrap recycling.

Specifications

| Modèle | Pont roulant électromagnétique QC | |||||

| Capacité de levage (t) | 16/3.2 | 20/5 | 32/5 | 50/10 | ||

| Portée (m) | 10.5-31.5 | |||||

| Hauteur de levage | 16/18 | 12/14 | 16/18 | 12/16 | ||

| Classe ouvrière | A6 | |||||

| Vitesse (m/min) | levage | Electromagnétique | 13 | 9.7 | 9.5 | 7.8 |

| Aux.hook | 14.5 | 12.7 | 12.7 | 13.2 | ||

| Trolley en déplacement | 44.6 | 44.6 | 42.4 | 38.5 | ||

| Déplacements de grues | 112.5/101.4 | 112.5/101.4 | 101.8/86.8 | 86.8/87.3 | ||

| Alimentation électrique | 380v, 50HZ, 3phase ou conception personnalisée | |||||

QY Type Insulation Hook Overhead Crane is a type of lifting equipment specifically designed for applications requiring an insulated environment, such as the power industry. It consists of a sturdy bridge, crane operating mechanism, hoisting mechanism, electrical equipment, crane hook and pulley, and insulation devices. To achieve electrical insulation, the bridge is constructed of special insulating materials. Insulation layers are placed between metal components to prevent current from flowing through the crane structure. It is widely used in various areas of the power industry, including transmission and distribution line construction, substation construction and operation and maintenance, and power equipment manufacturing and maintenance.

Specifications

| Nom | QY Type Insulation Hook Bridge Crane | |

| Capacité de levage | 5、10、16、16/3.2、20/5、32/5、50/10t ou sur mesure | |

| La portée | 7.5-35m | |

| Hauteur de levage | 10-18m/min | |

| Obligation de travail | ISO-A5/A6/A7/A8 | |

| Vitesse | Levage | 6-16m/min |

| Trolley en déplacement | 5~45m/min | |

| Déplacements de grues | 75-120m/min | |

| Alimentation électrique | 380V 50HZ 3PHASE ou personnalisé | |

| Température de travail | - 25℃-40℃ | |

The QB explosion-proof overhead crane is a lifting device designed specifically for use in environments with flammable and explosive gases or dust. Its main components utilize explosion-proof structures and materials, and it can be equipped with a variety of explosion-proof electric hoists or lifting mechanisms. It meets the strict national and industry requirements for explosion-proof levels. It is widely used in specialized industries with extremely high safety requirements, such as the petroleum, chemical, natural gas, military, and pharmaceutical industries.

Specifications

| Capacité de levage | 5t | 10t | 16t | 20t | 32t | 50t | 75t | |

| La portée | 10.5~31.5m | |||||||

| Les signes de l'antidéflagrance | ExdIIBT4(ExdIICT4) | |||||||

| Vitesse | Levage (m/min) | 5 | 4.3 | 4.2 | 4.1 | 3 | 1.9 | |

| Déplacement du palan électrique (m/min) | 19.6(14.6) | 20.5(14.6) | 20.5(13) | 20.5(13) | 20(12.3) | 20(12.3) | 19.1(15.3) | |

| Traveling a crane | 22.3(12) | 22.3(12)19(14.5) | 19(14.5)17(14.5) | 19(14.5)17(14.5) | 17(14.5)19.4(14.5) | 19.4(14.4) | 19.3(14.4) | |

| Traveling of a crane | 43kg/m | 43kg/m ou QU70 | QU70 ou 90*90 | QU80 ou 90*90 | QU100 | |||

| Modèle opérationnel | Crane rail recommendation | |||||||

| Obligation de travail | A4 | |||||||

| Alimentation électrique | Selon vos demandes | |||||||

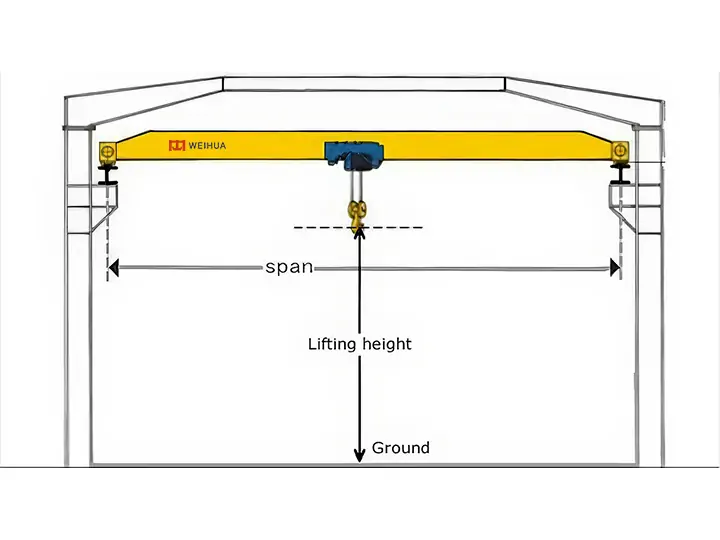

We are a crane manufacturer based in China, providing custom crane services to customers worldwide. If you would like a custom overhead crane, please leave a message on our website with the following information, and one of our professionals will contact you:

Crane Type:

Capacité de levage :

Span (S):

Lifting Height (H):

Travel Length (L):

Power Supply (e.g., 380V 50Hz, three-phase):

Working Conditions and Materials to be Lifted:

Do you have an existing runway structure?

Please email us the above information or leave us a message, and our team will analyze your needs and provide a tailored solution. If you have any further questions, please feel free to contact our online customer service or contact us via email!

If your maximum load exceeds 8.5 tons and you need to lift repeatedly, choose the 10T model.

For frequent shift use (e.g., 2-3 shifts per day), choose the A5 duty class.

For spans exceeding 20 meters or working heights exceeding 12 meters, consider a double-girder model.

Tip: If you're unsure whether to choose a 10T or 12T model, we can simulate your load profile and recommend the most efficient solution.

We offer 24/7 online customer service to provide professional consulting services and help you select the right bridge crane for your application.

Yes, we can customize them to meet specific lifting needs. Factors such as lifting capacity, span, lifting height, and control options can all be tailored to your industry or application needs. Customization ensures optimal performance and efficiency.

Overhead cranes require regular maintenance and inspections to ensure they remain in optimal operating condition. We recommend a comprehensive maintenance and inspection every three months, including cleaning, lubrication, bolt tightening, and electrical system inspections.

This is a common concern among customers. We offer one-stop service, from delivery and installation to after-sales service. Our online customer service staff are available to assist you with any questions and provide after-sales documentation, such as operating manuals and maintenance manuals. If the issue persists, we can dispatch an engineer to your site.

Of course, we also have a professional team of technicians responsible for equipment installation and training guidance, and can provide you with on-site installation and commissioning guidance.

N'hésitez pas à nous laisser un message. Nous vous répondrons dans les 24 heures.

Soumettre une demande