Nouvelles de l'industrie

A gantry crane is a type of overhead crane that uses legs or wheels to move along ground tracks or rails. Unlike traditional overhead cranes, which are fixed to a ceiling or structure, gantry cranes offer greater flexibility and mobility. As a result, they are especially suitable for outdoor construction sites, warehouses, manufacturing plants, and machine shops where fixed cranes cannot operate effectively. In this article, we will describe the main components of a gantry crane and explain how it works, so that you can make full use of it in practice.

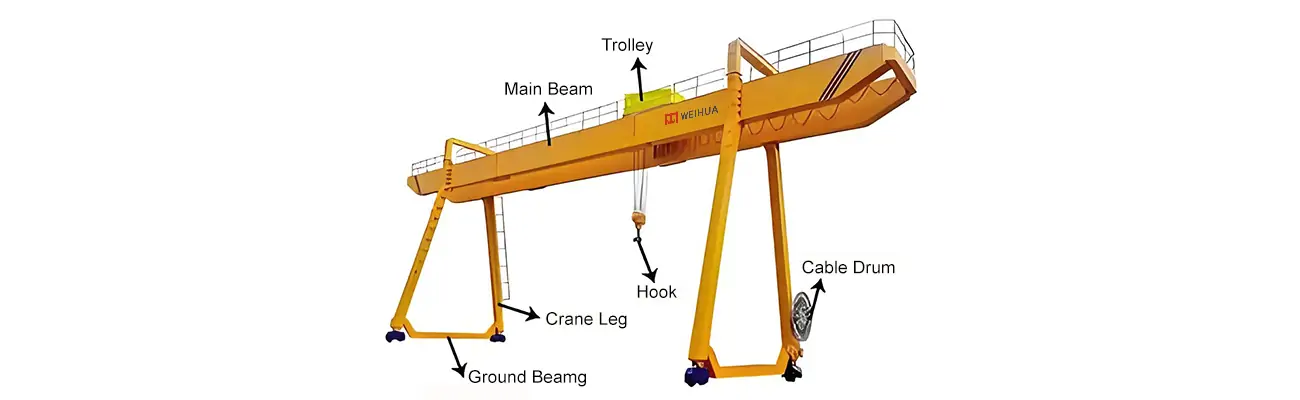

Gantry cranes are fundamentally based on the design of bridge cranes and additionally feature a unique portal frame structure, which consists of a horizontal main beam, rigid outriggers, and a running mechanism. A trolley carrying the hoisting mechanism moves along this bridge, thereby enabling both vertical and horizontal lifting and transportation of loads. As a result, gantry cranes are primarily used for material handling and installation tasks in a variety of settings, including open storage yards, shipyards, power plants, ports, and railway freight stations.

To understand the working principle of a gantry crane, we must first understand its main working mechanism, which consists of a hoist and trolley system, a bridge, and support legs.

The bridge is a horizontal beam that spans the entire space, supported by vertical outriggers. The bridge houses the crane and trolley system, which moves along tracks on the outriggers. This allows the crane to cover a wide area and provide a high degree of maneuverability within its operating range.

The core component of a gantry crane is the primary mechanism for lifting and lowering loads. It consists of a hook, cable, and pulley system, enabling the crane to precisely raise and lower heavy loads. The crane's design and lifting capacity are key factors influencing the overall performance of a gantry crane.

The bridge supports the trolley and enables it to move horizontally with the load.It enables precise load positioning, enhancing the crane's versatility in various working environments.

The outriggers are the vertical structures that support the entire crane. They are designed to provide excellent stability under significant weight. Outriggers can be fixed to the foundation or equipped with wheels (tires or rails) for mobility.

The end carts are located on top of each outrigger. These components house the motors and wheels, enabling the entire crane to move forward and backward along its tracks.

Modern cranes typically feature a dedicated operator's cab, cantilevered from the crane structure, providing the operator with a panoramic view. Many cranes also support ground-based remote control, allowing the operator to observe the load more closely and safely.

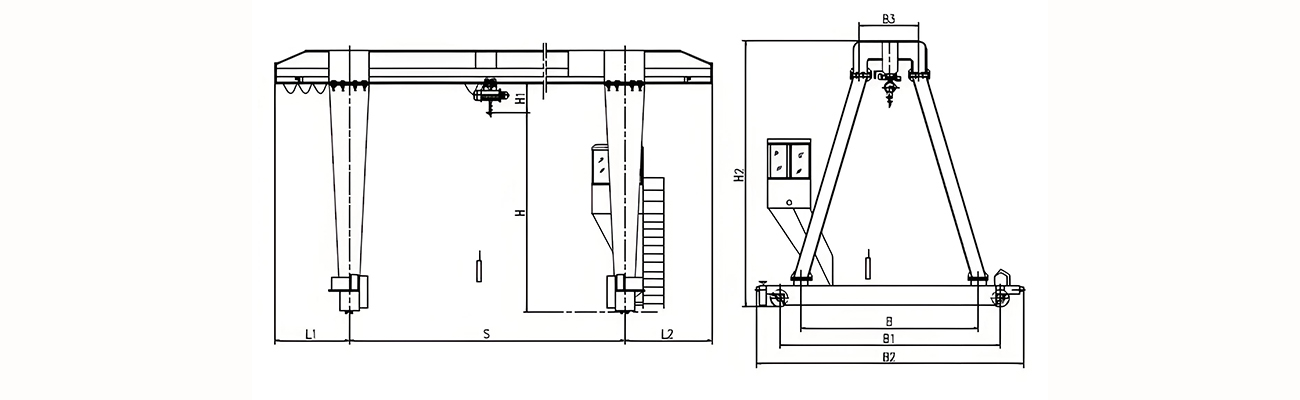

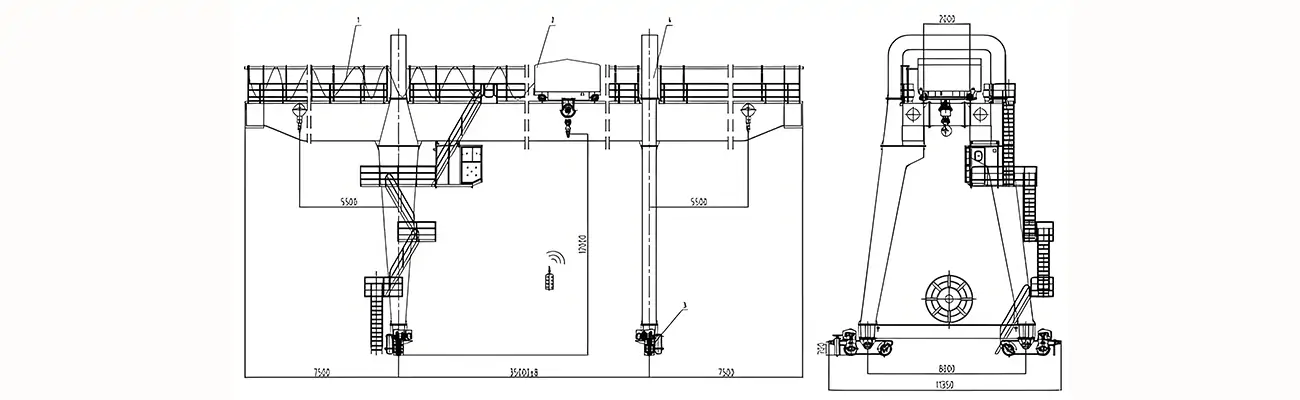

single girder gantry crane design

double girder gantry crane design

Gantry cranes operate on a clear principle, seamlessly integrating vertical lift and horizontal movement to precisely handle loads. This entire process involves the systematic interaction of various components, each performing a specific role to ensure safe and efficient lifting operations.

First, operators position the gantry crane within its work area. Then, depending on the type of gantry crane, they may place its outriggers on rails or directly on the ground. Once in position, the operator will inspect the area to ensure it is clear of obstructions.

Once the crane is in position, the operator will activate the hoist using the control system. The hoist will raise the hook or lifting device and connect it to the load. Once the load is secured, the operator can begin lifting.

After the load is lifted, the trolley moves horizontally along the bridge. One of the gantry crane's key advantages is its ability to move loads across large spans. The operator can maneuver the load to the desired location within the work area.

After the load is transported, the operator lowers it into position using the crane. The gantry crane's precision enables controlled positioning, whether positioning large steel beams in construction or unloading containers at a port.

The working principle of a gantry crane is different from other lifting equipment (such as overhead cranes) because it is highly maneuverable, especially rubber tire gantry cranes. These mobile gantry cranes have legs fitted with rubber tires, allowing them to move flexibly on the ground.

In summary, a gantry crane is a highly efficient material handling device. It utilizes a main beam structure that spans the site, along with a hoisting mechanism and a trolley that travels along tracks, to vertically lift and horizontally move heavy objects within a certain range. If you require a customized gantry crane solution, please feel free to contact us. Our professional team will provide personalized advice and assist you in selecting the most suitable equipment.

Date :

Date :

Soumettre une demande