Puentes grúa

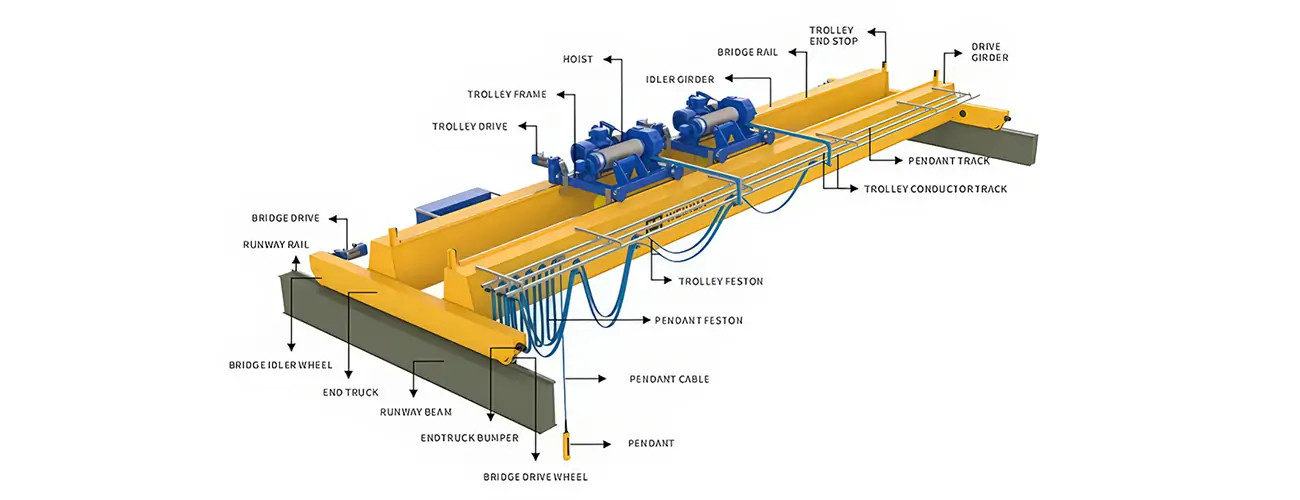

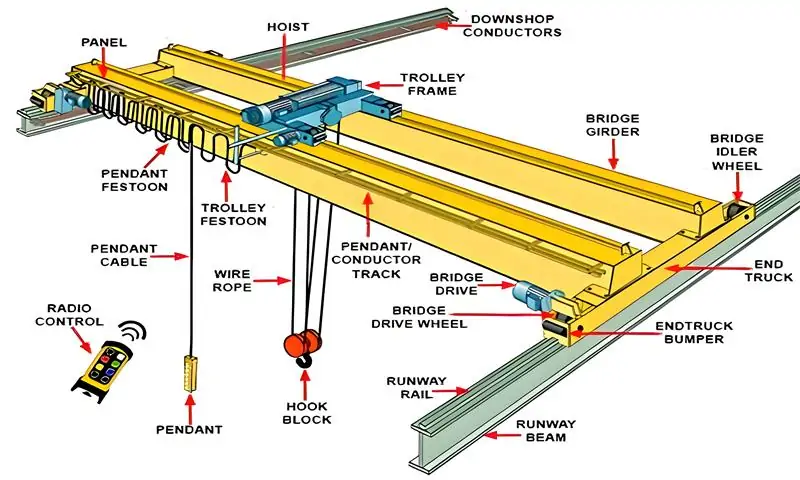

Double-girder cranes, also known as double-girder overhead traveling cranes or double-girder EOT cranes, feature two sturdy bridge girders, making them ideal for heavy-duty industrial applications. They consist of two main girders, an electric hoist trolley, end beams, an electrical system, and advanced safety features. This configuration provides secure support and stability for handling heavy loads over longer spans.

The double girder overhead crane consists of the main girder, end girder, trolley running mechanism, Overhead Travel Mechanism, hoisting mechanism, rail, cab, walking platform, and other parts. The functional characteristics of each part are as follows:

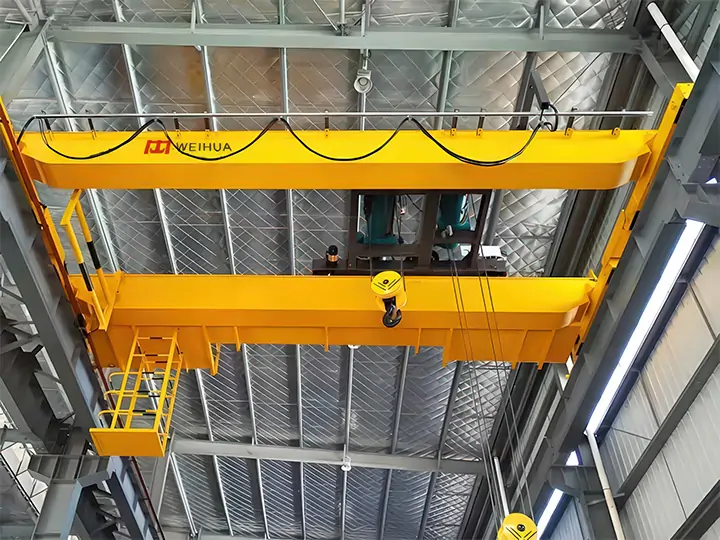

The Double Girder Double Hoist Crane utilizes two box girders or truss girders to provide greater rigidity and load carrying capacity. It is suitable for heavy loads from 20~500 tons or even higher (e.g., metallurgy, shipbuilding industry). The span range is 10~35 meters, suitable for large plants. Common types are LH double girder overhead crane and the NLH European double girder overhead crane.

NLH double-girder, double-hoist bridge crane with European-style hoist

LH double-girder, double-hoist bridge crane with wire rope hoist

Higher stability: The double-beam structure offers improved torsional resistance, making it suitable for precision lifting (such as wind turbine blade installation).

High scalability: It can be integrated with specialized lifting equipment such as magnetic lifters, grabs, and C-hooks.

Heavy industry: Steel mills (ladle handling), shipbuilding (pipe section lifting), and mining (large equipment installation).

Energy industry: Wind turbines, hydropower generators, and nuclear power pressure vessel lifting.

Large-scale logistics: Port container and heavy machinery transportation.

| Capacidad de elevación | T | 5 | 10 | 16/3.2 | 20/5 | 32/5 | 50/10 | ||

| Span | m | 10.5-31.5 | |||||||

| Velocidad | Main Hook Lifting | A5 | m/min | 11.3 | 8.5 | 7.9 | 7.2 | 7.5 | 5.9 |

| A6 | 15.6 | 13.3 | 13 | 12.3 | 9.5 | 7.8 | |||

| Aux. Hook Lifting | 16.7 | 19.5 | 19.5 | 10.4 | |||||

| Traveling with Crab | 37.2 | 43.8 | 44.6 | 44.6 | 42.4 | 38.5 | |||

| Cabin, remote control; ground handle | A5 | 89.8/91.8 | 90.7/91.9 /84.7 | 84.7/87.6 | 84.7/87.6 | 87/74.2 | 74.6 | ||

| A6 | 92.7/93.7 | 115.6/116 /112.5 | 112.5/101.4 | 112.5/101.4 | 101.4/101.8 | 75/76.6 | |||

| Operational Model | Cabin, remote control, ground handle | ||||||||

| Deber de trabajo | A5,A6 | ||||||||

| Fuente de alimentación | Three-phase A.C. 380V, 50Hz or customized | ||||||||

QD double-girder hook overhead crane is a heavy-duty industrial crane with a double-girder structure and a hook as a spreader to achieve precise lifting and horizontal movement.

High Practicality and Long Service Life: High-quality materials and rigorous craftsmanship ensure stable performance under prolonged use and frequent lifting operations, resulting in a long service life.

High Load Capacity and High Working Performance: The high lifting capacity enables the machine to handle a wide range of lifting weights, both light and heavy.

In steel and chemical plants,QD double-girder hook overhead cranes transport heavy equipment, steel, and chemical raw materials.

In rail transport, they assist in cargo loading and unloading.

At ports and terminals, they are a powerful tool for loading and unloading cargo, lifting containers, and handling bulk cargo.

| Modelo | Tipo QD | |||||||||

| Capacidad de elevación | t | 5 | 10 | 16/3.2 | 20/5 | 32/5 | 50/10 | 75/20 | 100/20 | |

| Altura máxima de elevación | Elevación principal | m | 16 | 16 | 16 | 12 | 16 | 12 | 20 | 22 |

| Max. lifting height | m | 18 | 14 | 18 | 16 | 22 | 22 | |||

| Span | m | 10.5-31.5 | 13.5-31.5 | 13-31 | ||||||

| Velocidad de elevación | Principal | m/min | 11.3 | 8.5 | 7.9 | 7.2 | 7.5 | 5.9 | 6.1 | 3.9 |

| 15.6 | 10.4 | 10.7 | 9.8 | 9.5 | 7.8 | 6.1 | 4.9 | |||

| Aux. | 14.6 | 15.5 | 15.5 | 10.4 | 7.2 | 7.2 | ||||

| Velocidad de desplazamiento del carro | m/min | 37.2 | 37.2 | 40.0 | 40.0 | 42.6 | 38.5 | 38.4 | 33.90 | |

| Velocidad de desplazamiento de la grúa | A5 | m/min | 68.3/70.4 | 70.4/71.8/73.4 | 70/72/72.8 | 70/72/73 | 74.2/75.1 | 75/75/72 | 53.9 | 61.7 |

| A6 | 68.3/71.1/88.9 | 71.1/74.2/74.2 | 70/72/73 | 71.3/73.6/73.6 | 75 | 75/75/74 | 77.8/67 | 61.8 | ||

| Fuente de alimentación | 3 Frase A.C. 50Hz 380V u otros | |||||||||

Grab Overhead Crane, also called "Waste Handling Crane," is a kind of heavy lifting equipment specially used in waste transfer stations, incineration plants, landfills, recycling centers, etc. It is mainly used for gripping, handling, stacking, and sorting all kinds of solid wastes, such as domestic wastes, industrial wastes, and construction wastes.

High-strength structure: Utilizes a heavy-duty double/box girder design to withstand high-frequency, high-intensity operating environments.

Anti-corrosion treatment: Key components (such as wire ropes and motors) are coated with anti-corrosion coatings or made of stainless steel to resist corrosive gases and liquids in waste.

Intelligent control system: Utilizes variable frequency speed regulation for smooth operation and precise positioning. It also features automated operation, programmable control, and integration with waste disposal systems.

Port Industry: Bulk carrier loading and unloading (coal, ore), on-site material transfer and stacking, and containerized bulk cargo loading and unloading (such as grain and fertilizer).

Power Industry: Coal unloading, stacking, and loading, boiler ash cleaning and transfer, and desulfurization limestone processing.

Metallurgical Industry: Blast furnace raw material transportation (ore, coke), scrap steel recycling and smelting, and slag and steel slag cleaning and transfer.

| Capacidad de elevación | 5 ton~60 ton |

| Span | 10.5 meter~31.5 meter |

| Altura de elevación | 18 meter~28 meter |

| Velocidad de elevación | 34/39 m/min |

| Long traveling speed | 84~113 m/min |

| Cross traveling speed | 37~46 m/min |

| Alimentación | AC 380V 50Hz |

| Clase trabajadora | A6 |

European double-girder overhead cranes conform to European standards and feature compact structure, smooth operation, variable frequency control, and a small footprint. They consist of two main beams, end beams, a hoisting mechanism, and a traveling mechanism. The hook moves between the main beams to lift or move heavy objects.

Smaller Size and Lighter Weight: Compared to traditional bridge cranes, European double-girder bridge cranes feature a more advanced design, smaller size, and lighter weight.

Low Headroom: The maximum distance between the hook and the ceiling is minimal, effectively utilizing factory space.

Low Noise and Low Energy Consumption: Utilizing European standard motors and drive systems, these cranes operate quietly and consume 20%-30% less energy than traditional cranes.

Automotive Manufacturing: Handling parts on assembly lines, such as lifting large components like engines and gearboxes.

Aerospace: Assembling and transporting aircraft parts, such as wings and fuselages.

Power Plants: Installation and maintenance of large equipment within boiler rooms, such as hoisting turbine generator

| Nombre del producto | QDXX type Puente grúa |

| Gorra | 3~100 toneladas, a medida |

| Span | 4,5~31,5 metros, Personalizado |

| Altura de elevación | 3~30 metros, a medida |

| Equipos de elevación | Carro eléctrico europeo |

| Trabajo | A5-A8 |

| Potencia | Personalizado |

| Temperatura | -20℃~40℃ |

| Índice de utilización del espacio | 90% |

| Presión de las ruedas | 10-50KN |

| Operación Vida | >30años |

| Presión atmosférica | Presión atmosférica estándar |

An electromagnetic bridge crane is a double-girder bridge crane equipped with a removable electromagnetic lifting magnet, which uses electromagnetic force to lift and transport metallic materials. It generates magnetic force through an electromagnetic coil to secure the workpiece, then uses the crane's hoisting mechanism for lifting and transportation.

Energy Efficiency: Electromagnetic cranes can adjust the electromagnetic force as needed, minimizing unnecessary energy consumption.

Safety and Reliability: They often have a backup power supply or mechanical locking device to prevent the cargo from accidentally falling.

Easy Maintenance: Compared to traditional hooks, electromagnetic suction cups have a simpler mechanical structure and are easier to maintain.

Steel and Metallurgical Industry: Used for handling and stacking steel ingots, steel plates, and structural steel (such as H-beams and I-beams), as well as for recycling and transporting pig iron blocks, scrap steel, and iron chips.

Metal Processing Industry: Used for material handling in processes such as cutting, stamping, and welding.

Scrap Metal Recycling Industry: Used for grabbing and sorting scrap steel, scrap iron, and metal from dismantled vehicles, and for conveying scrap metal in crushing lines.

| Capacidad de elevación | 5~64 ton |

| Span | 10,5~31,5 metros |

| Altura de elevación | 5~18 meter |

| Velocidad de elevación | 7.8~15m/min |

| Long traveling speed | 87.3~116.8m/min |

| Cross traveling speed | 37.2~44.6m/min |

| Alimentación | AC 380V 50Hz |

| Clase trabajadora | A5~A8 |

The insulated hook bridge crane consists of a strong bridge frame, crane traveling mechanism, hoisting mechanism, electrical equipment, crane hook block, and insulation settings. For electrical insulation purposes, there are special insulating materials in the bridge section. Insulating layers are provided between metal parts to ensure that electric current does not propagate through the bridge crane structure. The lifting mechanism also needs to be insulated to ensure safety when lifting electrically charged materials.

QY Type Insulation Hook Bridge Crane

Reliable insulation performance: Effectively isolates current, with insulation resistance of no less than 1MΩ at room temperature of 20°C-25°C and humidity ≤85%.

Reasonable mechanical layout: Easily maintains maintenance and overhaul, improving equipment utilization and maintaining a long service life.

Compact structure: Minimizes weight while maintaining the strength and rigidity of the hook bridge crane.

Non-ferrous metal smelting: Hook bridge cranes are suitable for smelting processes of non-ferrous metals such as aluminum, magnesium, lead, and zinc.

Electronics industry: Semiconductor manufacturing workshops, electronic component production workshops, and other related workplaces.

Power industry: Safely moves and installs large transformers and other electrical equipment in power plants, substations, and other locations where high voltage environments are common.

| Nombre | QY Type Insulation Hook Bridge Crane | |

| Capacidad de elevación | 5、10、16、16/3.2、20/5、32/5、50/10t o personalizado | |

| Span | 7.5-35m | |

| Altura de elevación | 10-18 m/min | |

| Trabajo | ISO-A5/A6/A7/A8 | |

| Velocidad | Elevación | 6-16 m/min |

| Viaje en tranvía | 5~45m/min | |

| Grúa viajera | 75-120 m/min | |

| Alimentación | 380V 50HZ 3FASE o personalizado | |

| Temperatura de trabajo | - 25℃-40℃ | |

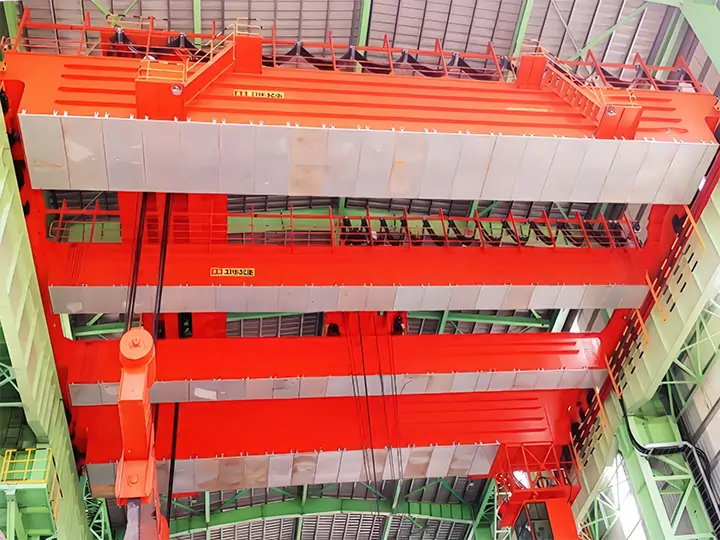

The overhead ladle crane is a double girder bridge crane, specially designed for the steel mill and used for lifting molten metal in metallurgy. It is particularly for handling molten metal, hot steel, and other high-temperature materials.

Safe and Stable: Equipped with overload protection, anti-collision devices, and limit switches, it ensures safe operation.

Flexible and Precise Control: Multi-axis control and variable frequency speed regulation enable flexible and precise operation, adapting to diverse operational requirements.

Adaptable to Harsh Environments: The QDY Bridge Foundry Crane is capable of operating in harsh environments such as high temperatures, high dust levels, and hazardous gases, featuring heat insulation, dustproofing, and corrosion resistance.

The QDY Bridge Foundry Crane is specifically designed for metallurgical processes, including molten metal handling, casting, forging, and rolling mill operations.

It serves steel mills, foundries, and non-ferrous metal facilities, transporting ladles, ingots, slabs, and heavy scrap.

It is suitable for high-temperature areas (≤50°C) near furnaces, ensuring safe material transfer in continuous production environments exposed to corrosive fumes or dust.

| Artículo | QDY overhead ladle crane |

| Capacidad de carga | 5 ~ 75 toneladas |

| Altura de elevación | Personalizado |

| Velocidad de elevación | Varía según la capacidad de elevación |

| Span | 10.5 ~ 31.5 m |

| Mecanismo de elevación | Carro con cabrestante |

| Clase trabajadora | A7/A8 |

| Temperatura de trabajo | -20 ~ +60 ℃ |

| Alimentación | AC-3Phase-220//230380/400/415/440V-50/60Hz |

| Tensión de control | DC-36 / 48V |

| Clase de protección del motor | IP54 IP55 IP65 |

| Vía de control | Cabina, mando a distancia inalámbrico, pulsador colgante |

| Dispositivo de seguridad | Factory, workshop, warehouse, power station, logistics,etc. |

| Área de aplicación | Factory, workshop, warehouse, power station, logistics, etc. |

| Color de la pintura | Yellow, Red, or Customized |

YZ four-beam steel foundry crane is a high-performance lifting equipment designed for the metallurgical and casting industries. Its structure mainly includes the main beam, end beam, lifting trolley, trolley running mechanism, and electrical control system.

Multiple Safety Mechanisms: Equipped with overload protection, dual emergency brakes, a hoist switch, and travel limit switches.

Electrical Safety: Protective grounding and high-temperature-resistant cables effectively prevent the risk of leakage and short circuits.

Thermal Protection: The cabin floor features tempered glass insulation and a thermally protective coating, providing a safe and comfortable working environment for the operator.

Steelmaking: Used in steelmaking plants for lifting high-temperature, heavy materials such as ladles, iron ladles, furnace charges, and ingots.

Foundry: Used for handling sand molds, castings, and molten metal. Its high load capacity and precise control are suitable for handling heavy and irregularly shaped workpieces during the casting process.

Scrap Handling: Used for handling and storing scrap in recycling and processing facilities.

| Lifting Capacity(t) | 200/50 | 225/65 | 240/80 | 280/65 | 320/80 | |

| Clase trabajadora | A7 | A7 | A7 | A7 | A7 | |

| Envergadura (m) | 28 | 27 | 22 | 21 | 24.5 | |

| Altura de elevación | Main hook | 26 | 32 | 25 | 24 | 28 |

| Auxiliary hook | 26 | 34 | 27 | 26 | 32 | |

| Velocidad | Main hook | 6 | 11 | 7 | 10 | 7.5 |

| Auxiliary hook | 10 | 11 | 9.6 | 12 | 10 | |

| Main Trolley | 41 | 41 | 35 | 30 | 29 | |

| Auxiliary Trolley | 38 | 39.5 | 38 | 39 | 39 | |

| Crane | 78 | 84 | 80 | 76 | 58 | |

| Max wheel load(kN) | 530 | 550 | 545 | 595 | 650 | |

| Steel track recommended | QU120 | |||||

| Power source | 3-Phase A.C. 380V 50Hz | |||||

The QB explosion-proof overhead crane is a type of lifting equipment specifically designed for use in flammable and explosive environments. All motors and electrical equipment are manufactured in accordance with international standards and regulations and incorporate exceptional safety features. The crane's hoisting mechanism utilizes an explosion-proof electric hoist, equipped with an explosion-proof motor and explosion-proof housing, eliminating potential ignition sources that could cause an explosion. With a lifting capacity typically ranging from 5 to 100 tons, this crane can meet the lifting needs of diverse environments.

Explosion-proof Design: All key components (motor, lifting mechanism, and electrical components) are made of explosion-proof materials.

Adaptable: Compatible with magnets, hooks, C-shaped hooks, and other options to meet the needs of various work scenarios.

Safe and Reliable Structure: The main beam and end beams are welded from high-quality steel, and non-metallic components are constructed of anti-static materials.

Chemical Industry: Production, storage, and transportation of petroleum, natural gas, pesticides, and fertilizers.

Military Industry: Production and storage of hazardous materials such as ammunition and fireworks.

Pharmaceutical and Food Processing: Transport of raw materials or finished products in alcohol extraction plants, flour, and milk powder production.

| Tipo | Explosion Proof Overhead Crane |

| Properties | Especificación |

| Capacidad nominal de elevación | 3t、5t、10t、16t、20t、32t、50t、75t、100t |

| Span | 7.5m-30m |

| Altura de elevación | 6m-24m |

| Velocidad de elevación | 5-20 m/min |

| Temperature of working environment | -25℃-"40 |

| Clase trabajadora | A3-A8 |

| Wheel diameter | 200-268mm |

| Working power supply | 3p A.C 50HZ 380V |

Weihua Crane specializes in providing customized lifting solutions that meet the specific needs of our customers. We can provide modular designs to suit diverse needs while ensuring structural soundness and standardized production.

If you have any specific requirements or need further assistance, please contact our team of experts and share your working demands. We will do our best to offer custom solutions and professional support.

No dude en dejarnos un mensaje. Le responderemos en 24 horas.

Enviar solicitud