Noticias del sector

Gantry cranes are large material lifting equipment used in ports, logistics, manufacturing, construction, and other locations requiring high-tonnage lifting and loading and unloading. Gantry crane prices typically depend on factors such as span, lifting capacity, and configuration level. In this article, we'll provide a detailed overview of gantry crane prices and the key factors that influence their cost.

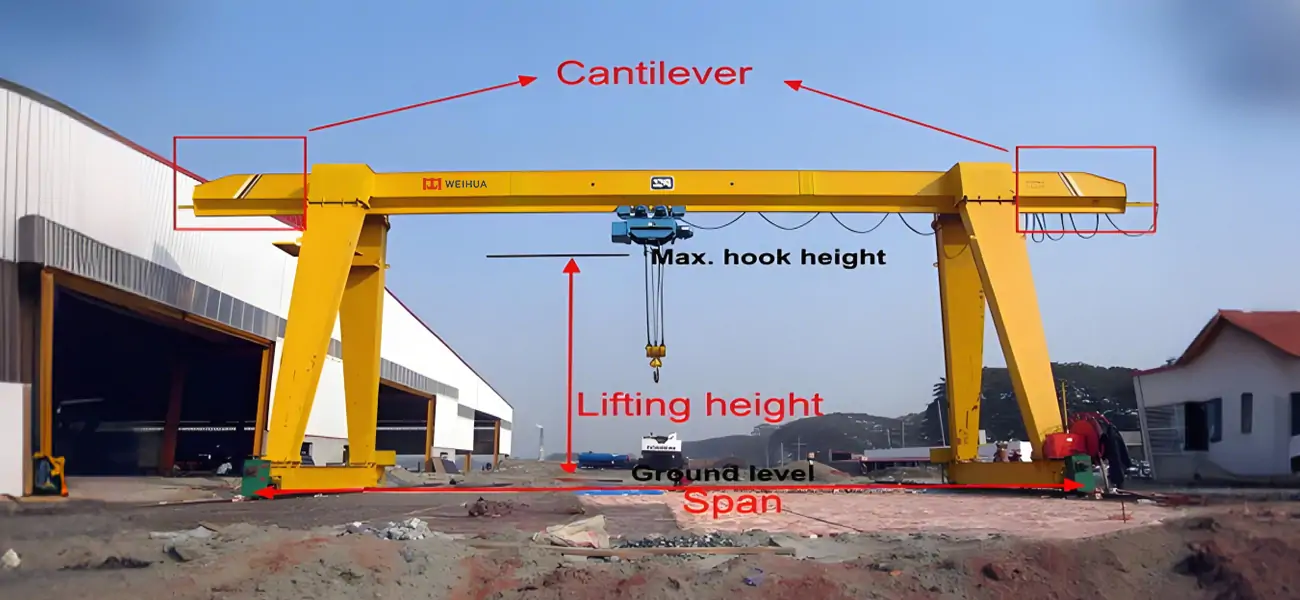

A gantry crane is a type of lifting equipment that operates on a track supported by a beam and outriggers. Its name stems from its "door"-like structure. Typically consisting of a main beam, outriggers, a trolley, and an electrical system, a gantry crane is capable of efficiently lifting and transporting heavy objects.

The factors that affect the cost and price of gantry cranes are mainly the following aspects, each of which will have a direct impact on the final quotation:

The lifting capacity of a gantry crane is one of the main factors that determine its cost. The higher the lifting capacity, the higher the price of the gantry crane. For example, the cost difference between a 10-ton, 50-ton, and 100-ton gantry crane is very significant.

Larger spans require longer main beams and rails, increasing material and manufacturing costs.

Higher hoisting heights require longer wire ropes, drums, and drive power, further increasing costs.

Single-girder gantry cranes have a relatively simple structure and are relatively low-cost.

Double-girder gantry cranes have a larger load capacity and are suitable for large-tonnage lifting, but they are more expensive.

Semi-gantry cranes, portable gantry cranes, lattice gantry cranes, container gantry cranes, and other types of cranes have significant structural differences, which also affects their prices.

Common inching controls are relatively inexpensive.

Higher-end features such as variable frequency drives, PLC automation, and remote control significantly increase the price.

If custom track or ground reinforcement is required, civil engineering and installation costs will increase.

The longer the site span, the higher the track laying and commissioning costs.

For standard indoor/outdoor environments, the cost is moderate.

Special environments such as high and low temperature, explosion-proof, and corrosion-resistant require specialized materials and designs, resulting in significantly higher prices.

Domestic standard configurations are relatively affordable.

Internationally renowned brands or those using European lightweight gantry crane designs are generally much more expensive.

Features such as overload protection, electronic anti-sway protection, automatic positioning, remote monitoring, and intelligent management will incur additional costs.

A1-A3 (Light): Less frequently used, simpler in design, and lower in price.

·A4-A6 (Intermediate): Suitable for frequent or moderate lifting operations, with higher prices.

·A7-A8 (Heavy): Suitable for heavy-duty operations in specialized industries such as wind power and ports, with more frequent use and the highest prices.

Different transportation methods also affect the cost of a gantry crane. For example, shipping prices vary depending on whether you choose LCL(less than Container Load), FCL(Full Container Load), frame, or bulk.

Installation and commissioning require a dedicated team, and labor costs and construction time will affect the total price.

The material used in the construction of a gantry crane also affects its cost. For example, some customers in Russia and Kazakhstan require the use of cryogenic steel, resulting in a more expensive gantry crane.

When purchasing a gantry crane, it's important to consider its type, lifting capacity, span, height, material, and the features required for your specific project. Understanding the factors that influence gantry crane prices can help you make an informed decision and select the right crane to meet your project needs.

Lifting capacity is one of the factors that affect the price of gantry cranes. Generally, the larger the lifting capacity, the higher the price. The following is the price range of common gantry crane lifting capacity:

| Capacidad de elevación | Span | Price Range |

|---|---|---|

2 ton gantry crane | 7.5-16.5M | $5,000 ~ $7,000 |

| 5 ton gantry crane | 7.5-16.5M | $13,500 to $15,500 |

| 10 ton gantry crane | 7.5-25M | $17,000 ~ $29,000 |

15 ton gantry crane | 7.5-25M | $21,000 ~ $36,500 |

50 ton gantry crane | 7.5-30M | $21,000 ~ $36,500 |

| 100 ton gantry crane | 7.5-30M | $85,500 to $205,500 |

Please note that the gantry crane price ranges provided in the table are estimates. For a specific model quote or customized solution, please contact us and provide your operating parameters (such as lifting capacity, span, and lifting height) for an accurate quote.

In addition to tonnage, the type of gantry crane is also an important factor affecting the price. The following are several common gantry crane types and their price ranges:

| Types | Span | Price Range |

|---|---|---|

| Overhead Gantry Crane | 5-30 m | $42,000 - $203,000 |

| Portable Gantry Crane | <12 m | $5,300 - $13,000 |

| Rail Mounted Gantry Crane | 5-31.5 m | $25,300 - $465,000 |

| Rubber Tyred Gantry Crane | 5-31.5 m | $60,000 - $160,000 |

| Container Gantry Crane | 5-31.5 m | $200,000 - $400,000 |

| Ship to Shore Gantry Crane | 5-31.5 m | $800,000 - $2,000,000 |

Note: The table content is for reference only. The actual price is subject to the actual specifications.

Since each customer's actual working conditions are different, the price of gantry cranes with the same tonnage may vary. In order to obtain the price of a gantry crane that meets your working conditions, please send us a detailed inquiry including the following information:

1. Lifting Capacity: Indicates the amount of weight the crane is required to lift.

2. Span: Specifies the required distance between the crane's supporting structures.

3. Lifting Height: Indicates the vertical distance the crane must reach to lift the load.

4. Power Supply: Provides information on the type of power source the crane requires.

5. Actual Operating Environment: Describes the operating environment of the crane, such as indoors or outdoors, and any harsh conditions it may be exposed to.

6. Special Requirements: List any custom or specific features required for your project.

Weihua Cranes can design and manufacture custom gantry cranes to meet your specific needs. Whether you require unique lifting capacities, specialized attachments, or other custom features, our team of experts can tailor a solution to meet your needs.

Gantry crane prices vary depending on tonnage, type, and configuration. Whether you're looking for a small workshop or a large port, a gantry crane can meet your needs. When purchasing, it's recommended to select the appropriate tonnage and type based on your budget and actual needs, and also consider factors such as equipment quality and after-sales service. For more details or a quote, please contact our service team.

Enviar solicitud