Hafenkräne

Ship-to-shore quay crane, also known as STS crane is the core lifting equipment at the front of the container terminal. The quay container crane is the key to the efficient operation of modern ports. It looks like a precise and strong giant, specializing in loading and unloading container ships. The main function is to connect the logistics transfer between vessels and terminals seamlessly. Quay container cranes could easily unload containers directly from ships to terminals, or vice versa. And then it is capable of loading containers accurately and precisely from terminals to ships to safeguard the smoothness of container transportation.

The metal structure has high strength and excellent stability, providing solid support for the whole equipment. No matter how much load it faces, it can be as stable as a mountain, guaranteeing the safe operation of the equipment. Weihua quay crane is in strict compliance with international standards such as FEM, DIN, IEC, AWS, GB, etc. This series of high standards ensures the quality and an internationally leading level.

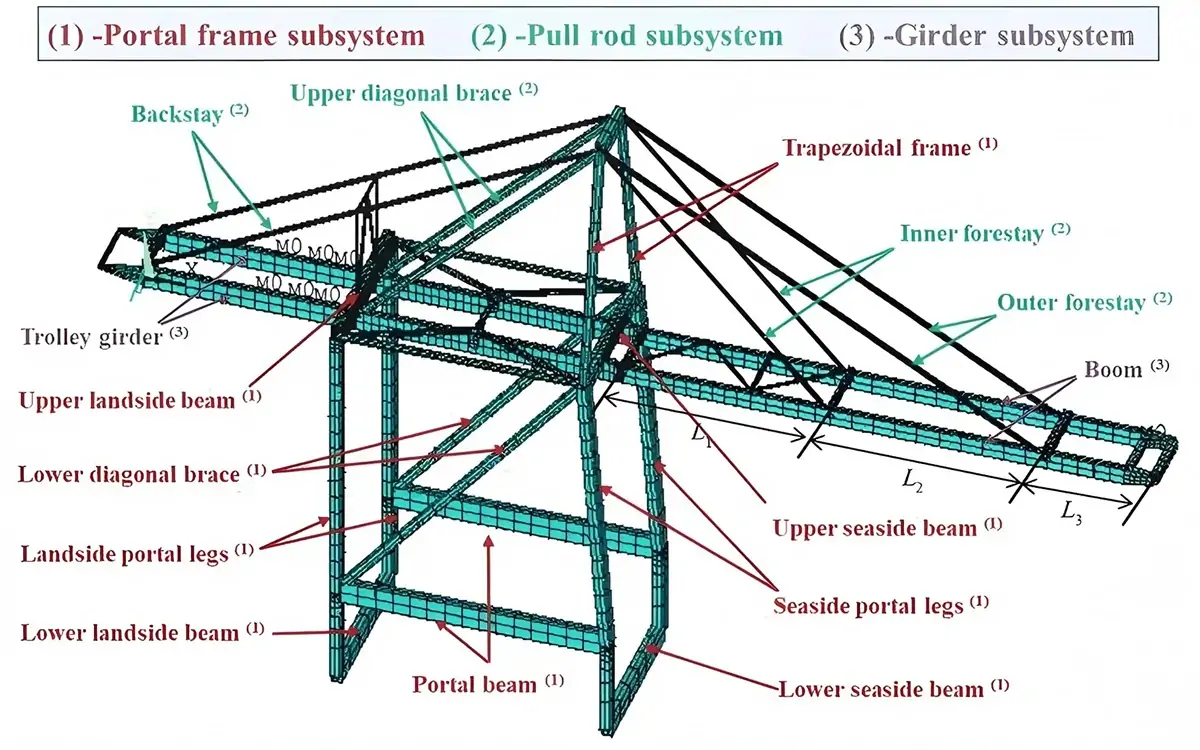

Quay cranes are mainly composed of Gantry Frame, Boom/Girder, Hoisting Mechanism, Trolley Travel System, Gantry Travel System, Spreader, electrical and control system, metal support structure, and other parts.

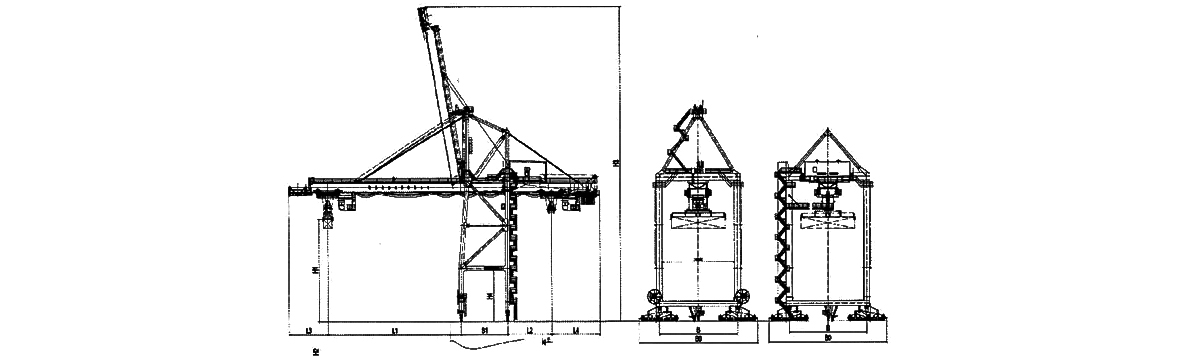

According to different structures and application requirements, shore bridge cranes can be mainly divided into the following types and features:

1. Conventional single trolley shore bridge: Adopts a single lifting trolley structure, lifting capacity of 30-50 tons, outreach distance of 40-50 meters, economical and practical, with low maintenance costs, suitable for small and medium-sized ports.

2. Double trolley quay crane: Adopting a front and rear double trolley design, the front trolley is responsible for ship-transfer platform handling, and the rear trolley is automatically docked to the AGV system, with a theoretical efficiency of 80-100TEU/h, applicable to large-scale automated terminals.

3. Girder lifting type: The girder can be lifted and adjusted to adapt to different ship heights and reduce wind resistance during non-operation.

4. Super post panamax quay cranes: outreach ≥ 65 meters, lifting height ≥ 40 meters, rated lifting capacity of 65 tons, can meet the needs of 22 rows of ultra-large container ship operations.

5. Low profile: optimized structure reduces the height of the whole machine, applicable to terminals or inland river ports with limited headroom.

6. Fully automated bridge: integrated intelligent system scheduling, automatic positioning (GPS accuracy ±15mm), without manual operation, suitable for intelligent automated ports with high throughput.

| Wichtigste technische Parameter | |||||||||||

| Grundlegende Parameter | Nenn-Hubkraft | Unter Spreizer | 35 | 41 | 51 | 65 | t | ||||

| Unterhaken | 45 | 50 | 61 | 75 | t | ||||||

| Hebehöhe | Obere Schiene | 37 | 25 | 50 | 35 | 58 | 40 | 62 | 42 | m | |

| Unterhalb der Schiene | 12 | 15 | 18 | 20 | m | ||||||

| Vorderseite Einsätze | 30 | 45 | 51 | 65 | m | ||||||

| Rückwärtige Einsätze | 10 | 15 | 15 | 25 | m | ||||||

| Schienenspur | 16 | 16/22 | 30.48 | 30.48 | m | ||||||

| Gesamtentfernung des Trolleys | 56 | 76/82 | 96.48 | 120.48 | m | ||||||

| Innerer Freiraum zwischen den Beinen | ≥17.5 | ≥17.5 | ≥18.5 | ≥18.5 | m | ||||||

| Lichte Höhe des mittleren Querträgers | ≥13 | ≥13 | ≥13 | ≥13 | m | ||||||

| Abstand zwischen Gantry Bumpern | ≤27 | ≤27 | ≤27 | ≤27 | m | ||||||

Geschwindigkeitsparameter | Hebegeschwindigkeit | Volle Ladung | 50 | 60 | 75 | 90 | m/min | ||||

| Keine Last | 120 | 120 | 150 | 180 | m/min | ||||||

| Fahrgeschwindigkeit des Wagens | 180 | 210 | 240 | 240 | m/min | ||||||

| GantryVerfahrgeschwindigkeit | 45 | 45 | 45 | 45 | m/min | ||||||

| Auslegerhubzeit (Einweg) | 5 | 5 | 5 | 5 | min | ||||||

The items listed in the above technical parameter table are for reference.

Weihua Global, as a leading quay crane manufacturer, specializes in customized container handling solutions for various port operations. Our cranes are modularly configured to support single/double spreaders, 35-65T lifting capacity, and automation systems with AI track control. With an outreach of more than 70 meters and a lifting height of 47.5 meters, our cranes provide high-performance equipment for mega-vessel operations and are CE/FEM certified.

Weihua can provide turnkey services including design solutions, port layout analysis, installation, and technical support. Welcome to cooperate with Weihua to jointly build intelligent quay cranes and improve the productivity of your terminal.

Sie können uns gerne eine Nachricht hinterlassen. Wir werden innerhalb von 24 Stunden antworten.

Antrag einreichen