Notícias do sector

An overhead crane is a heavy-duty material handling equipment, widely used in workshops, factories, warehouses, and other environments. As a key material handling equipment, overhead cranes ' safe and standardized operation is directly related to personnel lives, equipment integrity, and production efficiency. Therefore, a set of rigorous overhead crane operating procedures is particularly important. Next, this article will explain in depth the overhead cranes' operating procedures and daily inspection contents to help you discover around safety hazards and reduce accident risks.

European Overhead Crane

Explosion-proof Single Girder Overhead Crane

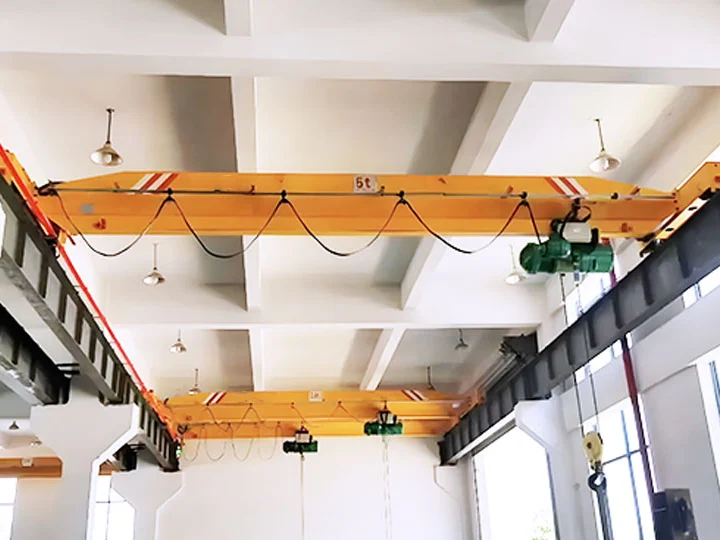

Double Hoist overhead crane

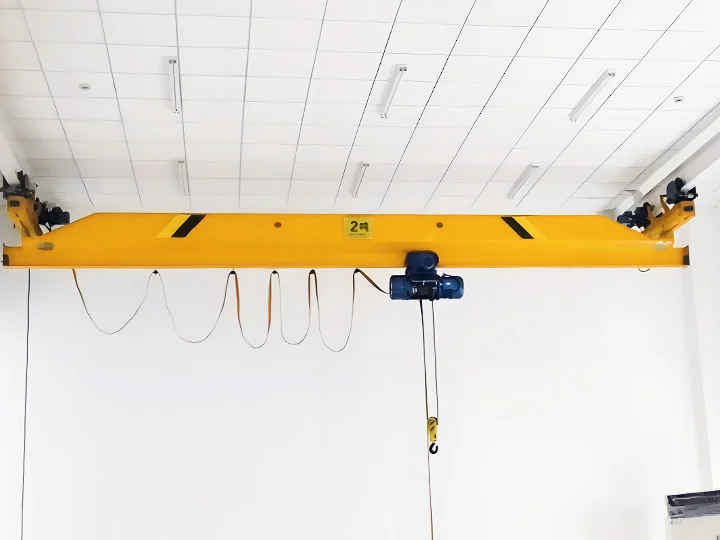

Single Girder Overhead Crane

Suspension Underhung Overhead Crane

Overhead Crane Safe Operating Procedure

Operators and businesses must be familiar with and strictly adhere to safe operating procedures and conduct detailed inspections before and after each operation. The following is a summary of the steps in the overhead crane operating procedures:

Notice: It is the essential responsibility of enterprises and operators to understand and be familiar with the overhead cranes' safe operating procedures.

| Inspection Project | Inspection Focus | Inspection Cycle |

|---|---|---|

| Main beam and end beam | Observe the bridge surface for deformation, corrosion, loose welding, cracking, etc. | 1 time per month |

| Mecanismo de elevação | Test whether the electrical, control, and operating systems are operating normally. | 1 time every 6 months |

| Traveling mechanism | Wear and damage of tracks, wheels, and brakes. | 1 time per month |

| Control system | Check the control switch, and other components are damaged, deformed, or corroded. | 1 time per month |

| Electrical equipment | Check electrical components, conductor bars, and grounding devices for exposed and damaged. | 1 time per month |

| Lubrication condition | Check whether the lubricating oil at each lubrication point is sufficient and uniform to ensure the smooth operation of mechanical parts. | 1 time per week |

When a bridge crane is working or stationary, all operators, commanders, and on-site assistants must always wear standard safety helmets and fasten their safety belts securely. This is a mandatory requirement of international special equipment safety regulations and on-site safety management systems. Properly wearing a hard hat can effectively reduce head injuries caused by accidents.

The above content introduces overhead crane operating procedures and a safety checklist. Mastering the standardized overhead crane operating procedures is the key to safe production and improving work efficiency. WEIHUA Crane is a professional crane Customization and manufacturer, committed to providing high-performance and high-reliability lifting equipment to help you effectively improve your production efficiency.

For customized overhead crane solutions, please feel free to contact us. WEIHUA's professional team will provide you with personalized advice and help you choose the most suitable equipment.

Enviar pedido