Notícias do sector

Overhead cranes are essential in factories, warehouses, and construction sites, lifting and moving heavy loads with precision. But how does an overhead crane work? Let's continue reading this article to learn about working principles, overhead crane parts, and uses of bridge cranes.

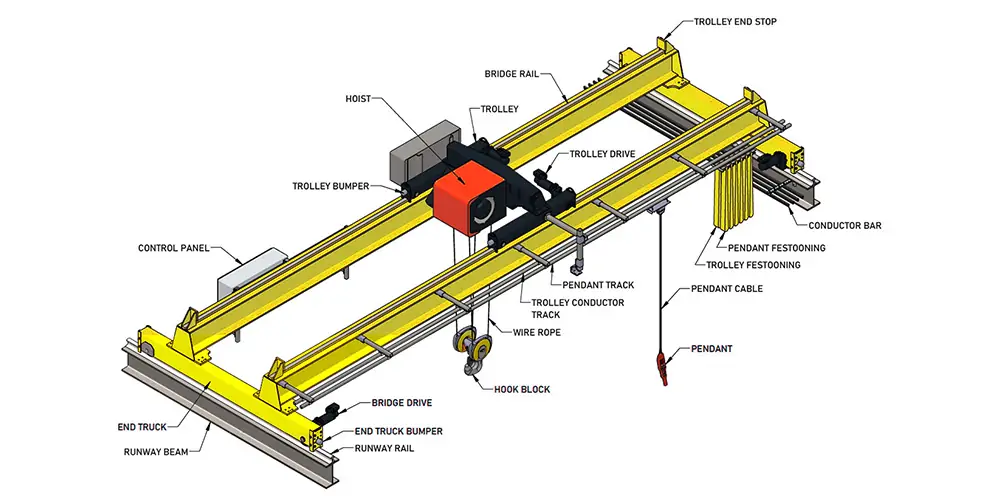

An overhead crane operates using a system of horizontal and vertical movements to lift, transport, and position heavy loads within a defined workspace. The crane consists of a bridge beam that spans the work area, supported by end trucks that travel along elevated runways. A crane trolley, mounted on the bridge, moves back and forth, carrying a hoist that raises and lowers the load via a hook, magnet, or other lifting attachment. The crane is powered by electric motors, with separate drives for bridge movement (along the runway), trolley travel (across the bridge), and hoisting (vertical lifting). Operators control the crane via a pendant station or radio remote, ensuring precise load placement while maintaining safety and efficiency.

When lifting a steel plate, the overhead hoist crane first moves longitudinally to the storage area, and then the trolley positions the hoist directly above the load. After the hook is lowered and engages the load, a combination of longitudinal and lateral movement delivers it to its destination, ultimately achieving precision positioning.

O overhead crane is mainly composed of five core components: lifting mechanism, operating mechanism, luffing mechanism, slewing mechanism, and metal structure. The functional characteristics of each component are as follows:

Lifting mechanism (to realize the function of lifting and lowering heavy loads): It is composed of lifting motor, reducer and wire rope system, adopting frequency conversion speed regulation to ensure the smooth operation, and equipped with double braking system to guarantee the safety.

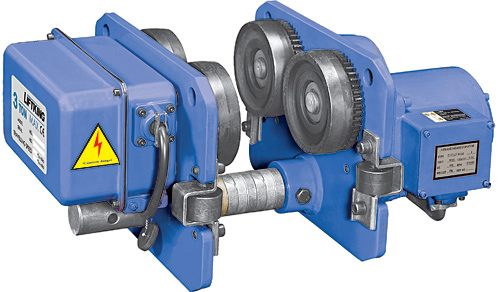

Running mechanism (to complete the movement of the whole machine): Trolley running mechanism: driving the end beam to travel longitudinally along the track, adopting a three-in-one driving device, equipped with a buffer and a limit switch;

Trolley running mechanism: Driving the electric hoist to move transversely, adopting frequency conversion control to realize precise positioning; equipped with a lifting and running mechanism, it can carry different spreaders to adapt to the needs of various working conditions.

Amplitude-variable mechanism (to adjust the operating radius): Amplitude-variable using a hydraulic system or steel wire rope, equipped with amplitude limit protection and load torque limiter;

Slewing mechanism (to realize horizontal rotation): Adopting a slewing bearing and planetary reducer, it can be operated with full slewing or a limited turning angle, equipped with a wind-resistant and anti-swing device.

Metal structure (to carry the overall load):

A crane trolley is a motorized component of an overhead crane that travels along the bridge girder, enabling horizontal movement of the hoist and load. It typically consists of a frame, wheels, a drive mechanism, and a lifting device (such as a hoist or winch). Trolleys can be powered (electric or pneumatic) for heavy-duty applications or manual for lighter loads.

Trolleys are classified into top-running (mounted on rails atop the girder) or underhung (suspended from the lower flange), depending on crane design. They are essential in industries like steel production, warehousing, and construction, where efficient and controlled material handling is critical.

The overhead cranes are commonly used in application scenarios such as manufacturing plants, warehouses, steel mills, and shipyards, with lifting capacities ranging from 1 ton to 1,000 tons. Below are the different types of overhead cranes used in various industries and application scenarios:

Single Girder Overhead Crane: It adopts a box-type single main girder structure with end beams at both ends, usually used with an electric hoist, featuring low cost, small headroom height, and easy installation, suitable for light and medium-sized material handling occasions in workshops, warehouses, etc. (lifting capacity ≤ 20 tons).

underhung bridge crane

Double Girder Overhead Crane: Through the combination structure of parallel double main girder and reinforced end girder, it has the features of larger lifting capacity (up to 500 tons or more), higher stability and the possibility of installing sub-hooks, and it is widely used in the heavy industrial fields such as iron and steel mills, power stations, and so on.

LH Type Double Girder Double Hoist Overhead Crane with Wire Rope Hoist

Hoist

Overhead Gantry Crane: It adopts the frame structure of box main girder and rigid outriggers, and moves along the ground track through the travelling mechanism of the trolley, featuring large lifting capacity (up to 500 tons or more), strong wind resistance (configured with windproof anchoring device) and wide operation range (the span can be customized), and so on. Its double-beam structure with frequency conversion drive system can realize heavy-duty smooth operation (speed 0.5-20m/min adjustable), especially suitable for wind power generation, hydropower stations, bridge construction, shipyards, container terminals, and other open-air heavy lifting scenarios. It can be configured with grabs, electromagnetic suction cup,s and other special spreaders according to the needs to meet the loading and unloading of steel, containers, and other large materials and transfer needs, and is an irreplaceable key lifting equipment in the field of heavy industry.

KBK Free Standing Bridge Crane System: It adopts modular rail system and rigid lightweight beam structure, and realizes quick assembly through standardized connectors, featuring light deadweight (single rail load capacity up to 2000kg), flexible layout (can be articulated with multi-track turns) and precise positioning (manual/electric manipulation), etc. The system consists of an I-beam with a rigid, lightweight beam structure. Its track system is combined by I-beam and closed type rail, with electric chain hoist operation, especially suitable for automobile assembly line, precision instrument workshop and other need to frequently adjust the station of light and medium materials handling scene (covering 50kg-2 tons load range), according to the structure of the plant can be flexibly arranged straight line, curved or circular track network, to achieve the three-dimensional space of the materials conveyed accurately.

The above overhead bridge cranes can be customized for specific working conditions, and users can choose the most suitable solution according to the actual lifting capacity, space conditions, and working environment.

Need a Custom Overhead Crane Solution? Contact our experts today for a tailored system that fits your needs!

Data:

Enviar pedido