Overhead Cranes

5 ton overhead crane is widely used in modern industry for light material handling operations, especially suitable for factories, warehouses, workshops, and other scenarios. The following will comprehensively introduce the product types, features, design, and purchase suggestions of 5 tons overhead crane to help you choose the most suitable lifting solution according to the specific working conditions. Weihua Crane provides one-stop overhead crane solution, customized to meet specific working conditions.

5 tons 5 ton overhead bridge crane can be divided into many types according to the structural form and use scenario. Please choose the most suitable lifting equipment for your working conditions according to the following type characteristics.

Compact design, lightweight yet sturdy, and smooth operation, usually equipped with an electric wire rope hoist. Ideal for efficient handling of medium-tonnage loads, particularly in workshops with limited space for light to medium-duty operations.

Adopting European FEM standard design and manufacture, lightweight and modular design, usually equipped with European electric hoist. It is suitable for occasions with lower requirements on plant structure and lighter deadweight, equipped with frequency conversion speed control and smooth operation.

EquLB Explosion-Proof Single Girder Overhead Traveling Craneipped with explosion-proof electrical components, the wheel rim is made of non-sparking material, suitable for petroleum, chemical, and other hazardous environments. Widely used in petrochemical, flour mill, cement factory, and other scenes.

5 ton low headroom overhead crane is a kind of lifting equipment specially designed for places with restricted space height. The total height of the crane is significantly lower than the conventional overhead crane, suitable for limited height of the plant or the need to maximize the use of lifting space.

It is suspended on the existing roof structure of the factory or a specially designed lower chord beam. It maximizes the use of existing space while reducing the impact on the ground layout. It is widely used in material handling operations in compact space scenes such as factories and warehouses.

Designed for loading and unloading bulk materials with double or multiple flap grabs for granular or loose materials. Widely used in industries that require efficient handling of materials such as grain, coal, ore and waste. Such as ports, grain depots, coal yards and recycling plants.

A single girder overhead crane is the most economical choice in the 5-ton class. The main girder is mostly made of I-beam or combined cross-section, equipped with an electric hoist as the lifting mechanism. Its advantages include:

Cost-effective: saves about 30% of the initial investment compared to double girder construction;

Easy installation: lower load-bearing requirements for plant buildings;

Space-saving: small building headroom height requirement.

The double girder overhead travelling crane adopts main girder design, which makes the structure more stable.

Higher stability, significantly reducing load swing;

Higher working capacity, up to A5-A6 working class;

Longer service life, suitable for high-frequency use;

Compared with a double girder overhead crane, the effective lifting height of single girder structure is relatively low, the shaking in operation is more obvious, and the working class is usually not more than A3, which is not suitable for heavy workshop use.

Suggestion: For daily use of no more than 2-3 hours and limited budget, single girder cranes are preferred; while for continuous operation or precision lifting scenarios, double girder structures should be prioritized.

| Parameter category | Technical Specification | Optional Range/Remarks |

|---|---|---|

| Rated lifting capacity | 5 tons | Customizable non-standard series such as 5.3 tons, 6.3 tons, etc. |

| Working class | A3-A5 | |

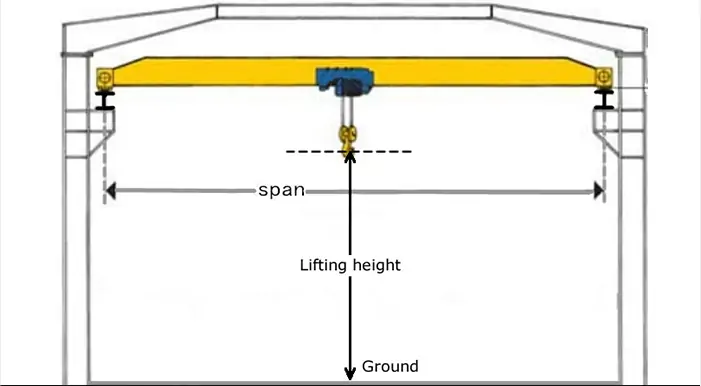

| Span(S) | Standard 7.5-31.5m | Customizable up to 35m (sectional structure) |

| Lifting height(H) | Standard 6/9/12m | Wire rope hoist can be extended to 30m (special design required) |

| Lifting speed | 8m/min (normal speed) | Double-speed type: 0.8/8m/min; frequency conversion type: 0.5-15m/min adjustable |

| Trolley running speed | 20-30m/min | Frequency control down to 2m/min (precision positioning) |

| Running speed of large vehicle | 20-45m/min | Outdoor type up to 116.8m/min |

| Main beam type | Single/double girder | Single girder (LD type): I-beam or combined cross-section |

| Double girder (QD type): positive/deviated box girder | ||

| Rail type | P24/P38/QU70 | QU-rail is suitable for heavy load conditions |

| Wheel diameter | Φ300-Φ500mm | Alloy steel wheels (HB≥300) are used for working class A5 and above. |

| Power source | 380V±10%, 50Hz, three-phase four-wire | Special voltage can be customized (such as 415V, 660V) |

| Lifting motor power | 7.5-13kW | Two-speed motor: 7.5/9.5kW |

| Inverter motor: 11-15kW | ||

| Running motor power | Small car: 0.8-1.5kW | |

| Large vehicle: 2×1.5-3kW | ||

| Control mode | Ground button/cab/remote control | Intrinsically safe remote control is required for explosion-proof occasions. |

| Standard safety device | Lifting limit switch, travel limit, emergency stop | |

| Optional safety devices | Overload limiter, anti-collision system, anemometer | Accuracy level: ±3%F.S. (overload protection) |

| Insulation class | Class F or H | High-temperature environment recommended H class |

| Operating temperature | -25℃~+40℃ | Low temperature type: -40℃ (special lubrication and electrical components) |

| High temperature type: +60℃ (special metallurgy) |

Manufacturing: machine assembly, production line material handling

Warehousing and logistics: loading and unloading of goods, stacking operations

Maintenance workshop: equipment installation and maintenance

Building materials industry: raw material handling

Metallurgy: small foundry operations

Crane Type:

Lifting Capacity:

Span (S):

Lifting Height (H):

Travel Length (L):

Power Supply (e.g., 380V 50Hz 3-phase):

Working Conditions & Materials to Be Lifted:

Do You Have Existing Runway Structures?

Send the above details via email or leave us a message, and our team will analyze your requirements to provide a tailored solution. If you have further questions, feel free to contact our online service or reach out via email!

Please feel free to leave a message. We will reply in 24 hours.

Submit Request