Grúas de pórtico

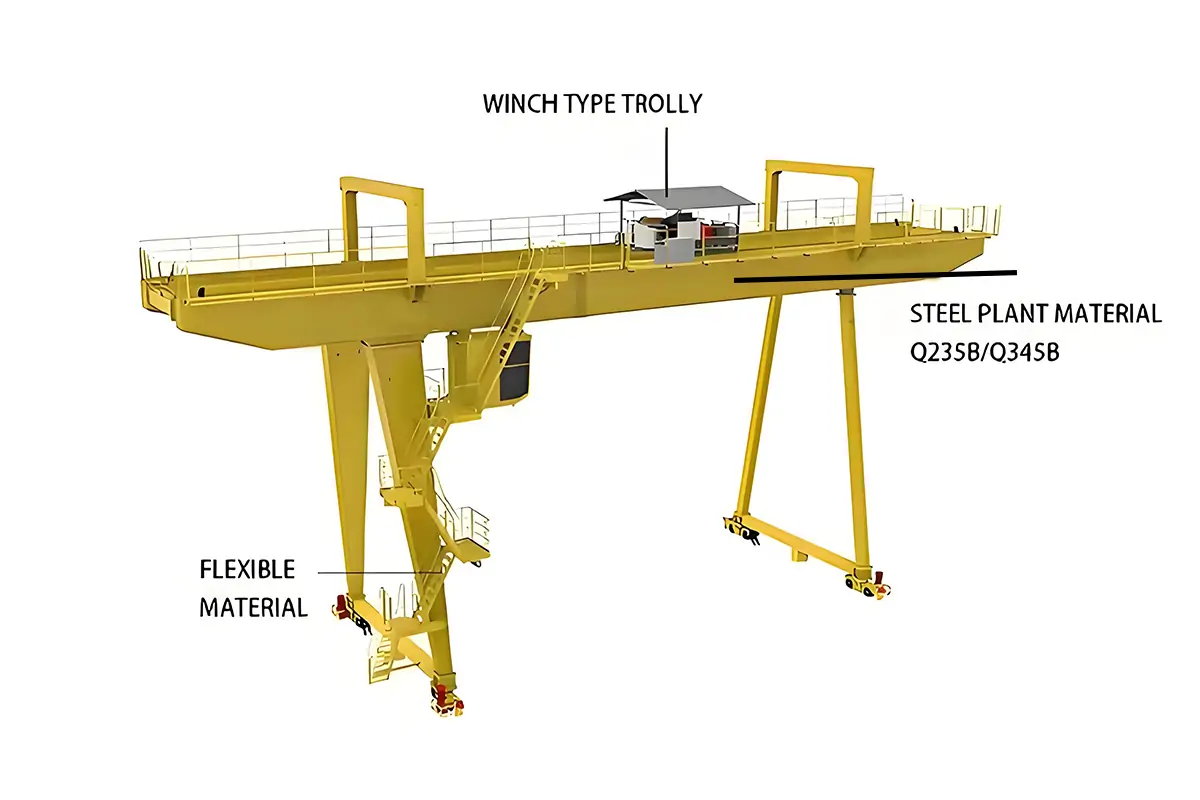

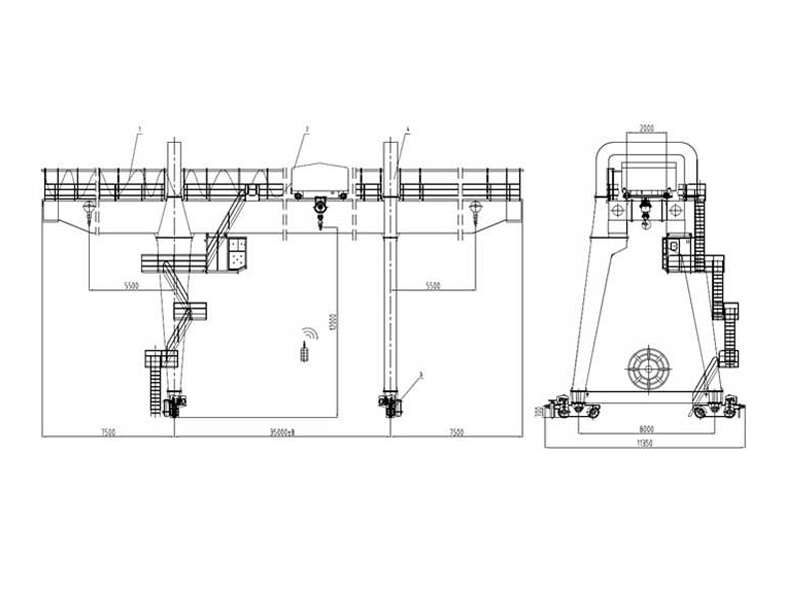

The European-style double-girder gantry crane adopts European design standards and advanced manufacturing processes, resulting in a lightweight structure (overall weight reduced by more to 15%) and a 10%-20% reduction in wheel pressure. It is suitable for medium to heavy-duty industrial applications. Its box-shaped main girder and tubular end beam design effectively reduce the overall height of the crane, increasing lifting space. Equipped with a three-in-one drive, PLC, and variable frequency control system, it offers smooth and precise operation and supports stepless speed control.

This crane complies with FEM/DIN standards and features a modular design, easy maintenance, low energy consumption, and low noise, making it widely used in ports, warehouses, steel mills, and logistics industries for efficient material handling operations.

Main beam

Outrigger

Ground beam

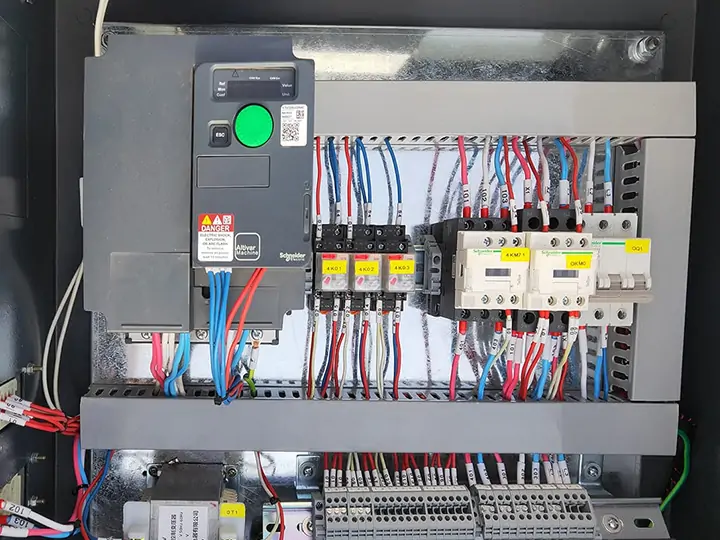

Electrical Components

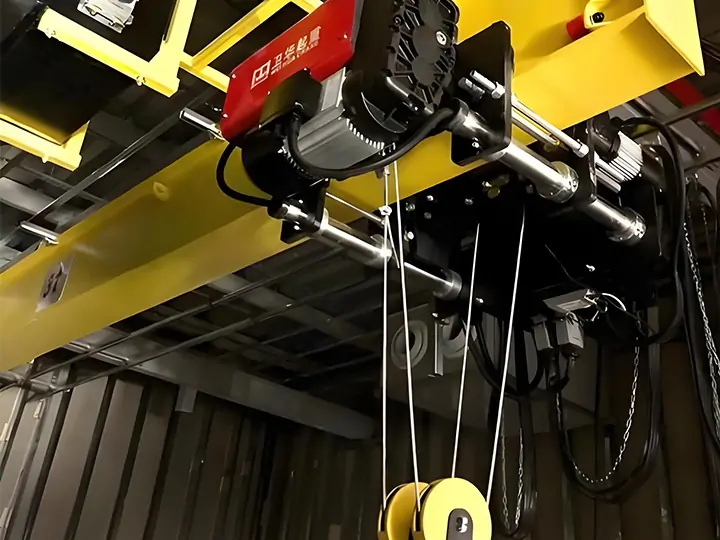

European style electric hoist

Wheelset

| Differences | European double-beam gantry crane | Traditional double-beam gantry crane |

|---|---|---|

| Structural weight | Lightweight design (15-30% lighter) | Traditional box-beam structure |

| Operation energy consumption | Energy saving of more than 30% | Conventional energy consumption level |

| Altura de elevación | Height optimization and 20% improvement | Fixed clearance requirement |

| Control accuracy | ±1mm positioning accuracy | ±10mm conventional accuracy |

| Maintenance cost | Maintenance-free bearings + centralized lubrication system | Conventional lubrication requirements |

| Service life | Design life of 25 years (FEM standard) | Generally 15-20 years |

| Ease of installation | Generally, 15-20 years | Large on-site welding workload |

European-style double-girder gantry cranes, with their high stability, precise control, and powerful load capacity, are widely used in industrial fields with high demands for material handling. Their main application scenarios include:

Heavy industrial manufacturing: Commonly found in steel metallurgy, large-scale equipment manufacturing, wind turbine blade assembly, and automotive manufacturing workshops, used for efficient handling and precise assembly of heavy components.

Logistics and port operations: Suitable for port container yards, railway freight yards, and large logistics centers, for the rapid transfer and stacking of containers and bulk goods.

Energy and chemical industries: Used in coal, petrochemical, and hydropower equipment installation, for lifting heavy equipment, and can be adapted to special environments through explosion-proof and corrosion-resistant designs.

Large component production and construction: Widely used in production bases and construction sites of large components such as precast concrete components and bridge components, enabling the handling and installation of heavy materials.

European double girder gantry cranes are designed and manufactured by advanced European FEM standards and consist of two main girders, an end beam system, a hoisting trolley, a control system, a cab, and so on. The following are the basic functional characteristics of the main components:

| Modo | Grúa pórtico europea de dos vigas |

| Capacidad de carga | 5 ~ 550 ton |

| Altura de elevación | 3 ~ 30 m (customized) |

| Lifting speed Single speed | 3 ~ 8 m/min; or customized variable frequency speed: 1 ~ 20 m/min; |

| Span | 5~35 meter |

| Mecanismo de elevación | Carro con cabrestante |

| Clase trabajadora | A3 ~ A7 |

| Temperatura de trabajo | -20 ~ 40 ℃ |

| Alimentación | AC-3Phase-220//230380/400/415/440V-50/60Hz |

| Tensión de control | DC-24 / 36V |

| Clase de protección del motor | IP54 IP55 IP65 |

| Vía de control | Ground handle control(Push button), wireless remote control, cabin control |

| Dispositivo de seguridad | Buffer,current overload protection,overload device,power failure protection |

| Área de aplicación | Factory, workshop, warehouse, power station, logistic, etc. |

Weihua, a renowned Chinese manufacturer and supplier of European-style double-girder gantry cranes, provides comprehensive solutions from design and FEM-certified manufacturing to installation and maintenance. We hold CE certification and ISO 9001 quality system certification, and our products strictly adhere to FEM standards. Our cranes have lifting capacities ranging from 5 to 500 tons and support customized features, widely used in steel, port, wind power, and large-scale manufacturing industries.

For customized crane solutions, please contact our engineering team for a free consultation and project evaluation.

No dude en dejarnos un mensaje. Le responderemos en 24 horas.

Enviar solicitud