Noticias del sector

Overhead cranes are indispensable heavy-duty material handling equipment in factories, warehouses, ports, and other locations, capable of efficiently lifting and moving heavy objects. However, like any mechanical system, overhead cranes experience wear and tear, leading to malfunctions and operational problems. Regular maintenance is crucial for maintaining the durability and optimal performance of bridge cranes. This article will explore some valuable maintenance tips to keep your overhead cranes in top condition at all times.

Overhead cranes mainly consist of main beams, rails, end beams, hoisting mechanism, trolley, control system, and power system. The functions of each component are described below:

Main Beam: Mounts the rails for the trolley's lateral movement.

End Beams: Mount the bridge crane's traveling mechanism.

Trolley Traveling Mechanism: Responsible for the trolley's lateral movement.

Top Traveling Mechanism: Responsible for the crane's longitudinal movement.

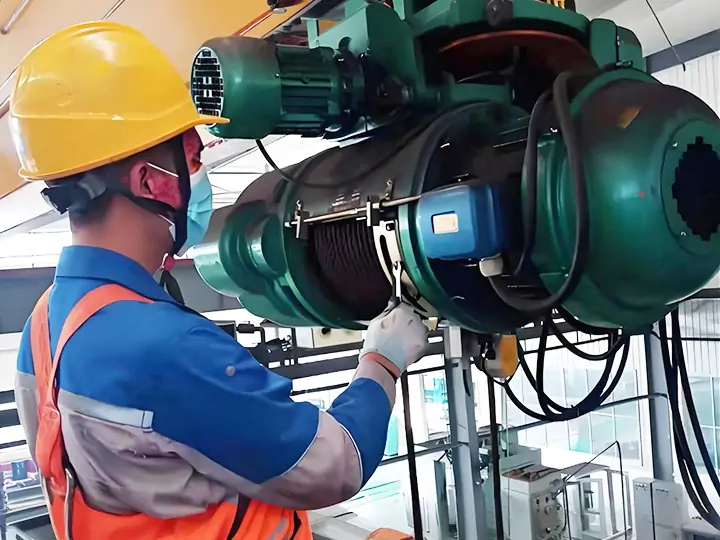

Hoisting Mechanism: Used for the vertical movement of goods.

Control System: The system used to operate the crane, including hook control (manual control), remote control, or cab control.

Power System: Provides power to the crane, including motors, cables, and power distribution units.

1. Working Environment Confirmation: Inspect the overall condition of the equipment and operating area to ensure it meets the manufacturer's design requirements and is free from operational obstructions.

2. Mechanical Component Inspection:

Check for oil leaks;

Confirm that the steel structure and transmission mechanism are free from abnormalities, misalignments, or deformations;

Inspect the lifting chain and wire rope for cracks, twisting, or excessive wear;

The load-bearing hook should be free from cracks and deformation and rotate freely;

Confirm that all lubrication points are properly lubricated.

3. Safety Device Function Verification:

Brakes and limit switches operate reliably; audio and visual alarm devices and indicators function normally.

4. Electrical System Inspection:

Control buttons, electrical equipment, and wiring should be intact, with no damage or exposed risks.

To ensure equipment safety and performance, a comprehensive inspection of the bridge crane must be performed weekly. The inspection content and standards are as follows:

Hook and Components: Inspect the hook (including rotational flexibility), pulleys, bearings, shafts, and other load-bearing components to confirm there are no cracks, excessive wear, or permanent deformation.

Track and Support Structure: Inspect the main beam, end beams, rails, and their connecting structures to confirm there are no cracks, abnormal deformation, or damage.

Test all limit switches to ensure accurate and reliable operation.

Check and test the function of each brake to ensure effective braking and no slippage.

Inspect wiring, terminals, control panels, and other electrical components to ensure there are no potential hazards such as overheating, aging, loosening, or exposure.

Check the gearbox oil level to ensure it is within the specified range; replenish or replace as needed according to the manufacturer's standards.

Lubricate bearings, gears, pulleys, and other moving parts according to the lubrication manual, ensuring the correct lubricant type and dosage are used.

All inspections and maintenance work must be recorded in detail and archived to facilitate tracking of equipment status and timely identification of potential risks.

To ensure the long-term performance and operational safety of the bridge crane, a systematic maintenance procedure should be performed every six months. This maintenance, in addition to routine inspections, focuses on in-depth maintenance and performance verification of key components and must be performed by qualified personnel.

Transmission System Oil Change: Completely replace the gearbox lubricating oil in the hoisting and traveling mechanisms according to the manufacturer's technical specifications, remove worn metal debris, and ensure good lubrication and smooth operation of the transmission system.

Brake System Inspection and Adjustment: Inspect the wear of brake pads, the surface condition of brake wheels, and the sealing of the hydraulic system. Accurately test and adjust the braking torque and brake clearance to ensure they meet safety standards and operate reliably.

Rated Load Test: Conduct static load (1.25 times rated load) and dynamic load (1.1 times rated load) tests to verify the stiffness and strength of the main beam and the operating performance of the mechanism under full load, ensuring its safe load-bearing capacity.

Wire Rope/Chain Maintenance: Conduct a comprehensive inspection of the wire rope for broken strands, wear, and deformation, and the chain for elongation and damage. Clean and lubricate according to specifications, and replace as necessary according to the scrap standard.

Load-bearing Component Maintenance: Inspect the hooks (including anti-disengagement devices), pulley blocks, bearings, and shafts for wear and cracks. After thorough cleaning, apply sufficient lubricant to ensure smooth operation.

Electrical System Maintenance: Check the insulation of the wiring, the tightness of the terminal block connections, and the condition of the contactor contacts. Clean the dust inside the control cabinet to ensure a clean working environment and normal function of electrical components.

A systematic inspection of the crane's main structure will be conducted, including the main beams, end beams, outriggers, and track system. Special attention will be paid to checking for fatigue cracks, localized instability, excessive deformation, or loose bolt connections to ensure structural integrity.

All safety protection devices will be comprehensively tested, including but not limited to limit switches, overload limiters, braking systems, and emergency stop devices. Simulation tests must be conducted to verify the accuracy and reliability of their operation, ensuring effective triggering under abnormal conditions.

A thorough inspection of the entire electrical system will be conducted, covering power supply conductors, motors, resistors, all terminals, and control cabinets. The aging of components, insulation performance, and connection reliability will be assessed, and functional tests will be performed on the control circuits.

Dynamic load (typically 1.1 times the rated load) and static load (typically 1.25 times the rated load) tests will be performed according to regulations to verify the structure's load-bearing capacity, stiffness, and overall performance of the mechanism under full load.

Inspect the wire rope (or chain) for wear, broken strands, and deformation, and determine its condition according to the scrap standard. Perform flaw detection and thorough lubrication on load-bearing components such as hooks, pulley blocks, and bearings, and replace any components that have reached the end of their service life or are damaged.

Properly maintaining records is crucial for crane maintenance and inspection. Having accurate documentation makes it easy to review the crane's maintenance history and is extremely useful for post-inspection reviews.

Below are some examples of information types you should include in your maintenance and inspection record reports:

Equipment ID: ______________

Equipment Name/Location: ______________

| Category | Artículo | Details / Findings | Personnel / Signature |

| 1. Basic Information | Date | ____ Year ____ Month ____ Day | |

| Type of Service | □ Daily Check □ Weekly Inspection □ Monthly Inspection □ Semi-Annual Maintenance □ Annual Inspection | ||

| Performed By | Signature: | ||

| 2. Work Performed | Items Serviced/Inspected | e.g., Brake adjustment, wire rope inspection, main girder visual check | |

| Components Involved/Replaced | e.g., Hoist brake lining, Wire Rope (Spec: ______) | ||

| Method & Standard | e.g., Visual, Instrument Measurement (Model: ______) Standard: □ Manufacturer's Manual □ [Please specify] | ||

| 3. Condition & Data | Findings / Abnormalities | e.g., Brake gap is 2mm, within standard; minor scratch found on main girder (see photo ref.) | |

| Key Measurements | e.g., Brake Gap ____ mm, Wheel Flange Wear ____ mm | ||

| Photo/Data Reference | (e.g., IMG_20231027_001) | ||

| 4. Conclusion & Recommendation | Final Disposition | □ OK for Service □ Monitor, Plan Next Check: ____ Year ____ Month ____ Day □ Fault Found, Requires Immediate/Scheduled Repair | |

| Follow-up Action Recommended | e.g., Recommend to replace hoist wire rope within 30 days; recommend NDT for girder scratch. | Reviewed By: |

Instructions for Use:

Filling: Record specific details in the "Details / Findings" column. Check the appropriate box "□".

Attachment Management: Photos taken on-site and data printouts should be marked with a unique reference number corresponding to this form.

Filing: After each task is completed, this form must be signed by the performer and reviewer, then promptly archived in the equipment's technical file for centralized security management and easy retrieval.

Standardized and regular maintenance and inspections are fundamental to ensuring the long-term safe and efficient operation of overhead cranes. Strictly following this guideline can help you effectively prevent safety accidents, reduce unexpected breakdowns and maintenance costs, and minimize production delays caused by sudden equipment downtime.

If you have any questions during crane maintenance, the technical team at Weihua Cranes is always your reliable support. We are happy to use our professional experience to support you and jointly ensure the stable operation of your equipment.

Enviar solicitud