Noticias del sector

Gantry cranes are heavy-duty material handling equipment widely used in workshops, factories, ports, and other locations. The safe and proper operation of gantry cranes is directly related to personnel safety, equipment integrity, and production efficiency. Therefore, a set of rigorous gantry crane operating procedures is particularly important. This article will provide an in-depth explanation of gantry crane operating procedures to help you identify safety hazards and reduce accident risks.

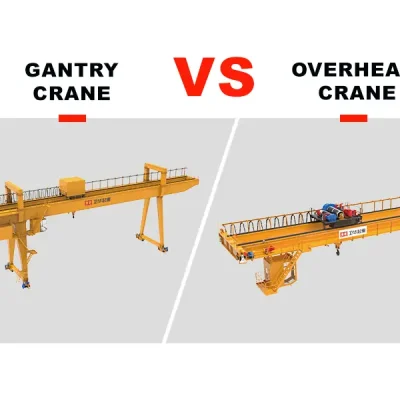

Gantry cranes are based on the design of bridge cranes and feature a unique portal frame structure consisting of a horizontal main beam, rigid outriggers, and a running mechanism. A trolley carrying the crane moves along the bridge, enabling the vertical and horizontal lifting and movement of loads. Gantry cranes are primarily used for handling and installation operations in open storage yards, shipyards, power plants, ports, and railway freight stations.

Mastering the correct and standardized use of gantry cranes is key to ensuring production safety and efficiency. Operators must not only understand the working principles of the equipment but also be familiar with and strictly adhere to safe operating procedures, understand the functions and status of key components, and conduct detailed inspections before and after each operation.

Before operating a gantry crane, always perform a pre-operation inspection to ensure the crane is in good working order. This pre-operation inspection should include checking the following components:

Structural Integrity: Inspect the crane structure for any signs of damage, such as cracks or corrosion. Ensure all structural components are in good condition and free of defects.

Hoist and Trolley: Inspect the hoist and trolley for proper operation, including brakes, limit switches, and load-bearing components. Ensure the hoist and trolley are free of obstructions and properly lubricated.

Controls and Safety Devices: Test controls and safety devices, such as limit switches, emergency stop buttons, and overload protection systems. Ensure all controls are functioning properly and clearly labeled.

Electrical Components: Inspect electrical components, including wiring, connectors, and power systems. Check for any signs of wear or damage, and ensure all electrical connections are secure.

Cargo Handling Equipment: Inspect slings, hooks, and other cargo handling equipment for any signs of wear or damage. Ensure cargo handling equipment is suitable for the expected loads and in good working order.

After completing the pre-operation inspection and resolving any issues, follow the following operating procedures when operating a gantry crane:

1.Personnel Training: Only trained and authorized personnel may operate gantry cranes. Operators should be familiar with the specific crane model they are operating and trained in safe operating procedures.

2.Load Capacity: Before lifting any load, confirm that the crane is capable of safely lifting and moving the load. Consult the gantry crane's load capacity chart to ensure the load does not exceed the crane's rated capacity.

3.Clear Communication: Establish clear communication between the crane operator and other personnel involved in the lifting operation. Use hand signals, two-way radios, or other communication devices to ensure everyone is aware of the progress of the lifting operation.

4.Clear Access: Ensure that the crane operating area is clear of obstructions for personnel, equipment, and materials. Clear access should be provided to prevent any obstructions that could interfere with crane operation.

5.Safe Lifting Practices: Use proper rigging techniques when attaching loads to the crane hook or lifting attachment. Before lifting, ensure that the load is balanced and secured in place.

6.Avoid Sudden Movements: Maintain smooth, controlled movements when operating the crane to prevent sudden jolts or swings in the load. Avoid sudden starts and stops to maintain stability during the lifting operation.

7.Overhead Clearance: When operating a gantry crane, be aware of overhead obstructions such as beams, pipes, or other structures. Ensure there is sufficient overhead clearance to accommodate the crane and the load being hoisted.

8.Emergency Procedures: Be familiar with the crane's emergency procedures, including how to safely lower the load in the event of a power outage or equipment failure.

After a gantry crane completes a lifting operation, it is crucial to follow post-operation procedures to ensure the crane is properly secured and ready for use. The post-operation procedures are as follows:

Shutdown Procedures: The gantry crane should be parked on the stop line, secured with a clamp, and the hook raised to its highest position.

Post-Operation Procedures: Zero the controller, disconnect the power supply, and securely close and lock the control room doors and windows.

Post-Operation Inspection: Perform a post-operation inspection to verify that the gantry crane is in good condition and free of any damage or issues that occurred during the lifting operation.

The above content introduces the operating procedures for gantry cranes. Mastering standard gantry crane operating procedures is key to safe production and improved work efficiency. Weihua Crane is a professional crane customization and manufacturer, committed to providing high-performance, highly reliable lifting equipment to help you effectively improve production efficiency. For more information, please feel free to contact Weihua's professional team for a free quote.

Date:

Enviar solicitud