Hafenkräne

The shipyard gantry crane is a kind of port crane designed for the shipbuilding industry. It is mainly used for lifting the hull sections, assembling parts and turning over the hull. The load capacity is 100~2000 tons, which can meet the needs of large ship construction.

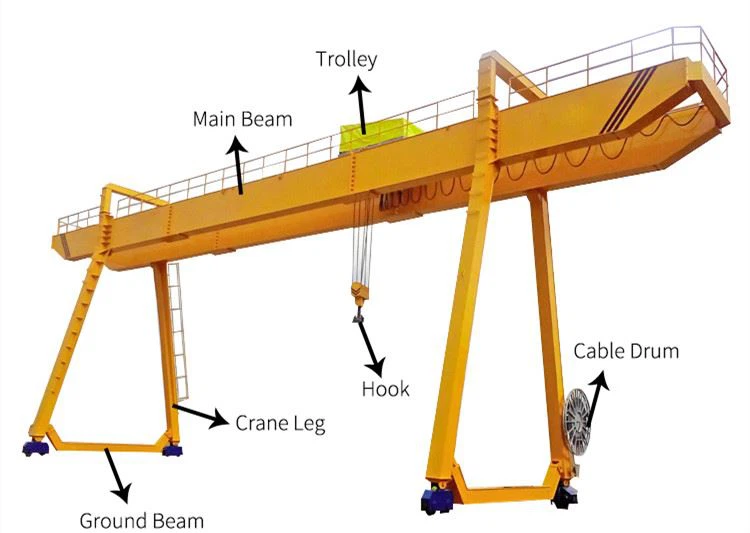

The equipment consists of a bridge, a trolley running mechanism, a trolley and electrical equipment. The bridge adopts a box-type welded structure, which runs smoothly and is flexible to operate. The shipbuilding gantry crane has multifunctional characteristics, such as lifting up and down, transporting sections, turning over the hull, etc.

WEIHUA provides shipyard gantry crane customized design and manufacturing services to meet the special needs of different shipyards. Free consultation, fast quotation, professional team to provide you with a one-stop crane solution!

Shipbuilding gantry crane is a kind of heavy lifting equipment mainly composed of a gantry structure, hoisting mechanism, trolley running mechanism, trolley traveling mechanism, and a control system. The following are the functional characteristics of each component.

Gantry structure: It consists of rigid outriggers, flexible outriggers, and main beams, forming a stable gantry frame with a maximum span of up to 185 meters, with good structural strength and wind resistance.

Lifting mechanism: Adopts Elektroseilzug or wire rope winch system, equipped with frequency conversion drive to realize high-precision (millimeter level) lifting and lowering control, the maximum lifting capacity can be up to 1500 tons.

Trolley running mechanism: The lifting trolley is mounted on the main beam, which can be moved transversely, and some models adopt a down double trolley design, which is convenient for hull segment turning and accurate positioning.

Trolley running mechanism: The whole machine can move longitudinally through the track running wheels, and adopts a separate drive + deskewing system to prevent runaway, adapting to the demand of long-distance operation in the dockyard.

Control system: Integrated PLC + frequency conversion drive, with automatic anti-shaking, synchronized lifting, electronic limit, and other functions, to enhance operational safety and energy efficiency.

Safety protection devices: Including torque limiter, anemometer, interlocking limit, etc., to ensure emergency braking under overloading, strong wind, and other working conditions.

Auxiliary structures: Such as S-shaped staircases, maintenance platforms, etc., to enhance the convenience of maintenance, and some high-end models are equipped with an elevator and an air-conditioned cab.

The working principle of the shipbuilding gantry crane (gantry crane) is to realize the lifting operation of heavy objects through the cooperative cooperation of three parts: hoisting mechanism, trolley running mechanism, and large trolley traveling mechanism.

The main workflow is as follows:

| Loading Capacity | 2×50+100t、2×75+100t、2×100+160t、2×150+200t、2×400+400t or customized |

| Spannweite | 50~185m or customized |

| Hebehöhe | 28~76/10~50m or customized |

| Hebegeschwindigkeit | Main hook lifting: 0~1 m/min or customized Aux.hook lifting: 0~5 m/min or customized |

| Cross Travel | 0~8m/min or customized |

| Long Travel | 0~25m/min or customized |

| Spannweite | 36~230m or customized |

| Lifting Mechanism | Electric winch trolley(single trolley, upper trolley, lower trolley, double trolley, or customize) |

| Electrical Parts Brand | SCHNEIDER, SIEMENS, CHNT, or customized |

| Motor Brand | ABM. ABB, WEG, JMS, XINDALI, SIEMENS, or customized |

| Reducer Brand | SEW, TAILONG, or customized |

| Brake Brand | JINGU, ZPMC, or customized |

| Arbeitspflicht | M7~M8 |

| Stromversorgung | AC-3Phase-220/230/380/400/415/440V-50/60Hz or customized |

| Control Method | Wireless remote control, cabinet control |

| Application Area | Shipyard, dock, power station, logistic, etc. |

| Color | Red, blue, or customized |

| Working Temperature | -20~40℃ or customized |

| Protection Class | IP54 / IP55 / IP65 |

| Safety Device | Buffer, current overload protection, overload device, power failure protection, lifting height limit device, traveling limit device |

The items listed in the above technical parameter table are for reference.

Sie können uns gerne eine Nachricht hinterlassen. Wir werden innerhalb von 24 Stunden antworten.

Antrag einreichen