Hafenkräne

Mobile Harbour Crane (MHC crane) is a kind of heavy duty mobile crane specially designed for port cargo handling, usually equipped with tire-type or rail-type traveling mechanism, which can be flexibly moved along the front of the quay, and can efficiently complete the tasks of ship loading and unloading of containers, break-bulk cargoes and general cargoes, as well as the transshipment of the yards and horizontal transportation, with the range of the lifting capacity from 30 tons to 500 tons. It supports quick switching of various attachments such as grab buckets, crane hooks, and container spreaders.

It is designed to resist corrosion (galvanized structure, marine grade protective coating) to cope with the high salt spray and high humidity port environment, and equipped with intelligent control systems (anti-sway technology, load monitoring) to ensure precise lifting. The Mobile Harbour Crane is widely used in the auxiliary operation of bridge cranes in container terminals, loading and unloading of bulk carriers, marine logistics of heavy loads, and outfitting in shipyards, etc., which is one of the core handling equipment in modern port hubs. It is one of the core loading and unloading equipment in modern ports.

The structure of the Mobile Harbour Crane mainly includes a support base, a rotating platform, a main arm, an auxiliary arm, a lifting mechanism, and an electrical control system.

The support base is the foundation part, usually with heavy-duty tires and all-wheel steering systems. It allows it to move freely within the port and adapt to different operating positions. The base also integrates a power system and a cabin control room, where the operator can control the driving and basic functions of the entire device.

Mobile Harbour Crane's rotating platform is mounted on the chassis and can rotate 360 degrees, providing all-around operational flexibility. The rotating platform is equipped with a main boom and an auxiliary boom, which is the main boom, usually made of high-strength steel, with good rigidity and load-bearing capacity. The auxiliary arm can be telescopic or folded as needed to meet the operating needs of different heights and distances.

The lifting mechanism is between the main arm and the auxiliary arm, and is responsible for lifting and handling heavy objects. Advanced frequency conversion speed regulation technology ensures stability and accuracy during lifting and falling, reducing the impact on cargo.

The electrical control system integrates PLC, sensors, and a variety of safety protection devices. In addition, remote monitoring and diagnostic functions allow operators to monitor the status of equipment in real time and promptly maintain and troubleshoot.

This design makes the mobile harbour crane an indispensable and important equipment in modern ports, which can handle loading and unloading tasks of various goods efficiently and safely, significantly improving the overall operational efficiency of the port. Whether it is containers, bulk cargo, or major cargo, MHC provides reliable support.

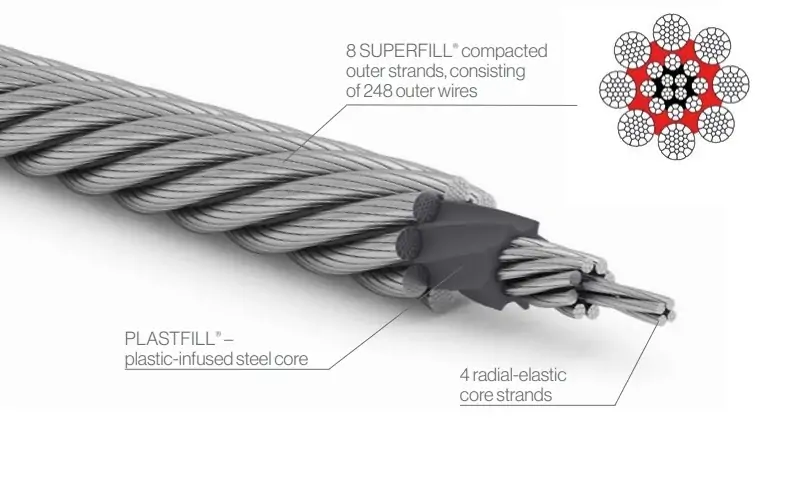

The harbour mobile crane rope GT8PZ (8 strands - internal plasticized) is a high-performance non-rotating steel wire rope specially designed for ships and harbour mobile cranes, adopting an 8-strand compacted structure, with good flexibility and high strength, suitable for the luffing system of container crane, overhead crane, and other equipment. The wire rope is produced by the drawing galvanization process combined with internal and external lubrication technology, with excellent corrosion and abrasion resistance, and can effectively resist salt spray, humidity, and other erosion in the marine environment. In order to ensure long-term reliable operation, the load management during the break-in period and the periodic inspection system need to be strictly followed.

| Heben Kapazität (t) | Working Range(m) | Hebehöhe (m) | Working speed | |||

| Min. | Max. | Obere Schiene | Unterhalb der Schiene | Slewing (m/min) | Traveling (m/min) | |

| 5 | 6.5 | 18 | 12 | 6 | 1.46 | 15 |

| 10 | 8.5 | 25 | 13 | 8 | 1.2 | 20 |

| 10 | 8.5 | 30 | 25 | 15 | 1.5 | 26 |

| 10 | 9.5 | 33 | 16 | 15 | 1.5 | 25 |

| 16 | 9.5 | 22 | 25 | |||

| 16 | 9.5 | 33 | 25 | 15 | 1.48 | 25 |

| 25 | 9.5 | 22 | ||||

| 16 | 10 | 35 | 22 | 15 | 1.5 | 25 |

| 25 | 10 | 25 | 18 | |||

| 25 | 10 | 33 | 26 | 16 | 1.4 | 25 |

| 35 | 10 | 25 | ||||

| 40 | 9 | 19 | 12 | 15 | 1 | 26 |

| 25 | 9 | 25 | ||||

| 40 | 11 | 30 | 23 | 12 | ||

Mobile Harbour Cranes are categorized based on design, mobility, and application:

| Typ | Tragfähigkeit | Working Radius | Driving mode | Main Applications | Environmentally friendly ports, low-emission operations |

|---|---|---|---|---|---|

| Small and Medium MHC | 100-125 tons | 46-64 meters | Electric/diesel dual power | Container, bulk, breakbulk loading and unloading | $58,000 - $250,000 |

| Medium MHC | 200-300 tons | 18-46 meters | Hydrostatic/electric drive | Ultra-large container ships, heavy cargo | $58,000 - $390,000 |

| Large MHC | 400+ tons | Kundenspezifisch | All-wheel steering hydraulic drive | Heavy-duty port handling, heavy-duty logistics | $78,000 - $500,000 |

| Electric/Low Carbon MHC | 100-150 tons | 40-60 meters | Full electric/hybrid drive | Environmentally friendly ports, low emission operations | $58,000 - $400,000 |

Container handling: Mobile Harbour Crane can quickly change the spreader to adapt to the handling needs of containers of different sizes. It is particularly suitable for small and medium-sized, comprehensive ports.

Bulk handling: By using specific grabs or nozzles, MHC can effectively load and unload bulk cargoes such as coal and grain.

Heavy-duty project cargo handling: For oversized or heavy cargoes, such as heavy machinery, modular building components, etc., MHC provides stable and powerful lifting capabilities.

Multi-purpose terminal operations: At terminals that need to handle multiple types of cargo, the multi-functional characteristics of MHC make it an ideal choice to cope with changing cargo handling needs.

Emergency response and special tasks: When fixed facilities are unavailable or in emergencies, Mobile Harbour Crane can quickly respond to emergencies, such as loading and unloading relief supplies after natural disasters.

Small ports and temporary terminals: Since it does not require large-scale infrastructure investment, MHC is suitable for small or temporary port operations.

Automation and smart ports: With modern technology, MHC integrates automation systems to achieve remote monitoring and operation, improve work efficiency, and reduce manual intervention.

Weihua Group is a leading manufacturer of mobile harbor cranes in China, with international certifications such as ISO, CE, GOST. With strong R&D strength, advanced production technology and globalized service network, we focus on providing customers with high-performance and intelligent port handling solutions. Currently, many mobile harbor cranes produced by Weihua have been widely used in major ports, logistics hubs and heavy industrial projects around the world.

Weihua can provide customized MHC solutions with different tonnages (100-500+ tons) and drive modes (electric/diesel/hybrid) according to customers' needs. Contact us today for customized solutions and exclusive quotes!

Sie können uns gerne eine Nachricht hinterlassen. Wir werden innerhalb von 24 Stunden antworten.

Antrag einreichen