Hafenkräne

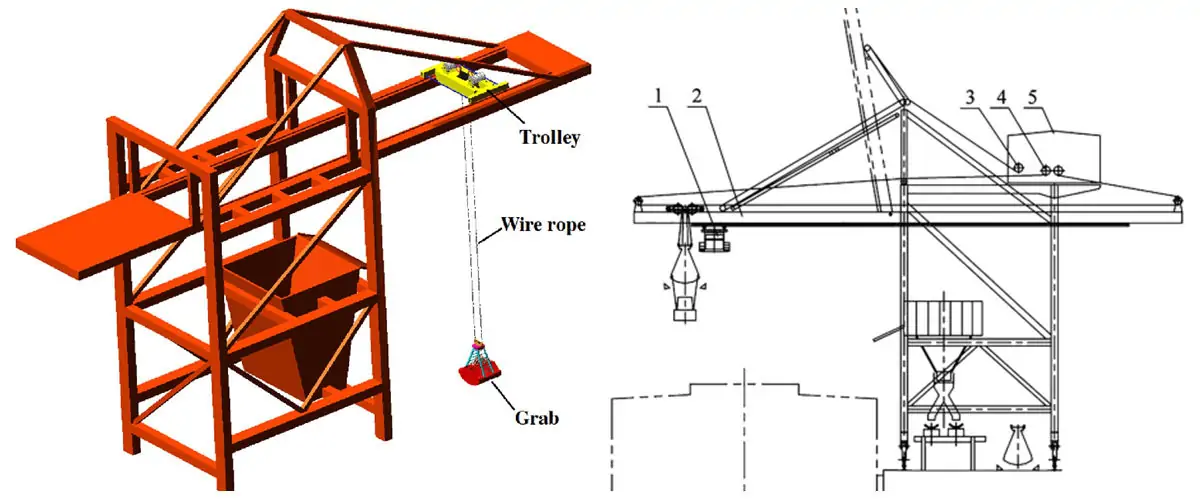

The Grab ship unloader crane (AGD grab unloader) is a type of efficient mechanical equipment specifically designed for bulk cargo loading and unloading. Its structural design is complex and sophisticated, aiming to meet the needs of fast, safe, and efficient operation.

First, the arm system is one of the core parts of the grab type gantry ship unloader, responsible for providing a sufficient working range. The arm is typically made of high-strength steel, providing good rigidity and stability to prevent deformation or shaking during large-scale movements. The arm connects to the fuselage through a hinge, and can be hydraulically or electrically driven to achieve variable amplitude.

Secondly, the grab device is the part that directly contacts the cargo. According to different cargo types (such as coal, ore, grain, etc.), different types of grabs can be selected, such as Double Flap Clamshell Grab Buckets or multi-petal grabs. The design of the grab should not only consider its grabbing efficiency, but also ensure that the cargo will not spill during the lifting process. Grab usually has an automatic opening and closing mechanism, which controls its opening and closing action through a wire rope or a hydraulic cylinder.

Third, the lifting mechanism is responsible for lifting and lowering the grab bucket, which includes components such as winches, wire ropes, and pulley blocks.

In addition, the travel mechanism enables the whole machine to move on the track so as to cover the entire length of the quay and reach different locations of the ship. The travel mechanism is usually driven by an electric motor and cooperates with a gear transmission system to achieve smooth and fast movement. In addition, in order to ensure the stability and safety of the equipment on the track, the travel mechanism is also equipped with anti-skid devices and limit switches.

Grab bucket type ship unloader is designed for coal, ore, and bulk material handling, with reliability in harsh port conditions. Ideal for Coal & Mineral Terminals, Bulk Cargo Ports, Industrial & Power Plant Docks. Features include auto-grab opening/closing, deep-digging optimization, and semi-automatic operation for precision handling. Equipped with anti-sway technology to minimize boom oscillations and extend equipment lifespan1. Need a custom solution? Contact us today!

A grab ship unloader crane mainly consists of the metal structure, mechanism, electrical control system, and other components.

| Rate production capacity | 1250 | t/h |

| Limit capacity | 1400 | t/h |

| Ship size | 50000 | DWT |

| Hoisting capacity | 32 | t |

| Spannweite | 22 | m |

| Base | 18 | m |

| Width of the belt conveyor | Out rail waterside 28, In rail waterside 12 | m |

| Luffing angle of boom | 0-80 | ° |

| Volume of hopper | 75 | m3 |

| Hubgeschwindigkeit | 110~150 | m/min |

| Travelling speed | 22 | m/min |

| Cabin travelling speed | 20 | m/min |

| Max.. working Load of Wheel | 2.5 | m |

| Boom hoisting time, one way | 7 | Min |

| Crane rail recommendation | 350 | kN |

| Max.. working Load of the Wheel | QU100 | |

| Motor capacity | 1240 | kW |

| Stromversorgung | ( H.V cable reel) 10kV 50 Hz | |

Coal terminal: Grab ship unloaders are widely used in coal loading and unloading operations, and can quickly and efficiently unload coal from cargo ships to storage yards or transport vehicles.

Ore terminal: Mineral resources such as iron ore and copper ore are usually transported by large cargo ships. Grab type ship unloaders can quickly and accurately unload these ores from ships for subsequent transshipment or storage.

Grain terminal: Agricultural products such as grains and soybeans occupy an important position in international trade. Grab ship unloaders can quickly complete loading and unloading tasks while ensuring the integrity of the goods.

Railway freight station: In some large railway freight stations, grab ship unloader cranes are to handle bulk cargo such as coal and ore transported by rail to ensure that the goods can be quickly transferred to the destination.

Inland ports and multimodal transport hubs: Inland ports and multimodal transport hubs are also important application scenarios for grab ship unloaders. They can effectively connect water, rail, and road transportation to achieve efficient cargo distribution.

Bergwerke: At the mine’s export dock or transshipment point, grab bucket ship unloaders are used to load mined ore onto ships, or to unload imported machinery and materials into the mine.

Sie können uns gerne eine Nachricht hinterlassen. Wir werden innerhalb von 24 Stunden antworten.

Antrag einreichen