Gantry Cranes

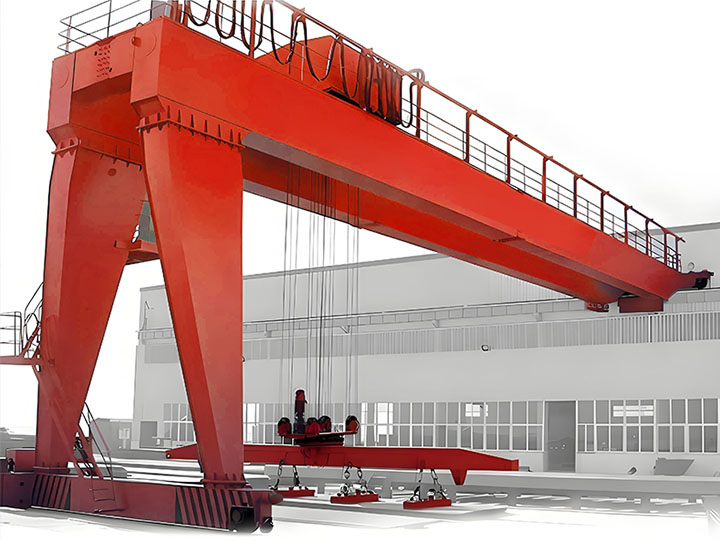

BMG semi gantry crane consists of two main beams, an electric trolley, and supporting leg on one side. This design allows one end of the crane to be fixed to a building wall, column or other structure, while the other end is supported by independent legs. Adopting this structure of gantry crane can fully utilize the site space. The main beam adopts a box-welded structure, and the large vehicle operating mechanism is driven separately. Semi-gantry crane operation includes ground operation, remote control operation, and cabin operation.

There are two conductive forms of semi-gantry cranes: cables and sliding contact wires. Such a structure allows the semi-gantry crane to cover a larger working area and provide an efficient material handling solution in limited spaces.

It is suitable for material loading, unloading, and handling in mining ports, railway freight stations, and open-air warehouses. And it can match with various lifting devices for special operations.

The semi-gantry crane is contactless, with module speed control, and can achieve micro speed and dual speed. The operation and lifting are particularly smooth. The electronic control is simple and close to the frequency conversion function. The control panel (handle) adopts 12V voltage and 380V voltage.

Users could put it in the industrial plants. The semi gantry crane could lift heavy equipment and machine parts, especially in a limited and small space. Also, it is suitable for loading, unloading, and stacking goods in logistics centers and warehouses.

| Product Name | BMG semi gantry crane |

| Lifting Capacity | 5-320 ton |

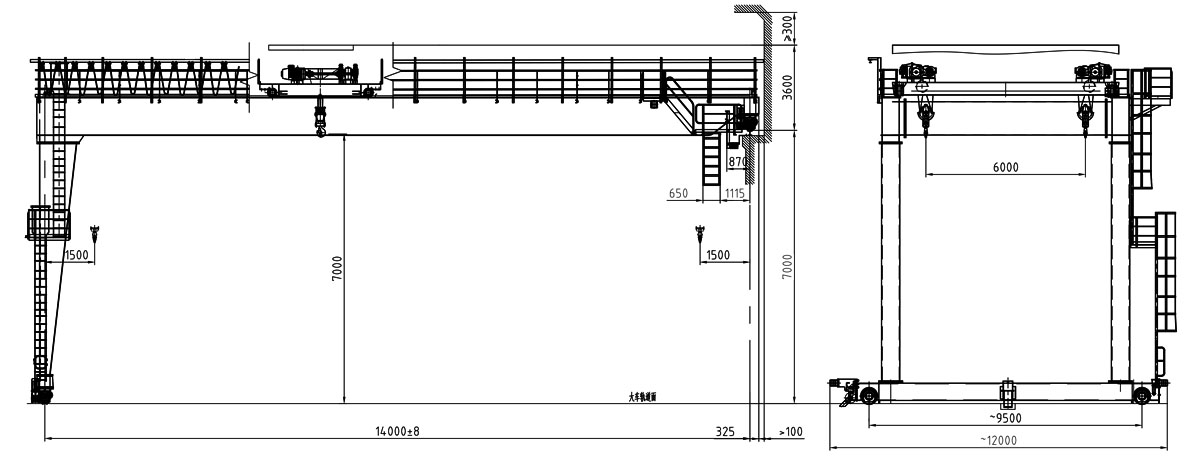

| Span | 6-24 meter |

| Lifting Height | 5-30 meter |

| Hoisting Speed | 1-10 m/min |

| Trolley Travelling | 35-40 m/min |

| Work Duty | A5-A7 |

| Power Source | As request |

| Operational Method | Ground Control+Remote Control |

Please feel free to leave a message. We will reply in 24 hours.

Submit Request