Аж үйлдвэрийн мэдээ

Electric hoists are an essential component of safe and efficient lifting operations, enabling businesses to lift and transport heavy objects in minutes. To ensure the integrity and efficiency of your reliable electric hoists, regular maintenance and inspections are crucial to effectively prevent malfunctions and reduce wear. This guide provides a professional overview of key maintenance points; please read on.

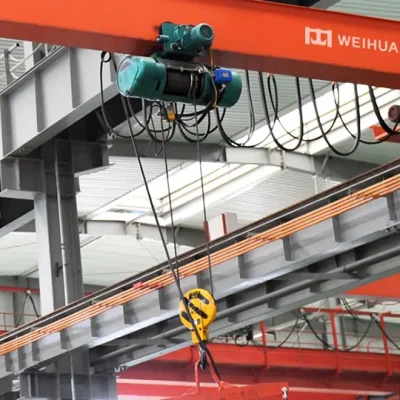

An electric hoist is a lifting device powered by electricity used for lifting and lowering loads. It mainly consists of a motor, gearbox, drum or sprocket, wire rope or load chain, hook assembly, braking system, control system, and limit switches. Workshops, warehouses, construction sites, and material handling industries widely use electric hoists to transport goods and materials with significantly higher efficiency and safety than manual handling.

| Category | Inspection Item | Inspection Standard / Requirement | Result (√/×) | Тайлбар |

| 1. Pre-Start Inspection | Visual & Structure | No cracks, oil leaks, abnormal noises, or unusual odors on structural parts | □ Pass □ Fail | |

| Wire Rope / Chain | No broken wires, kinks, corrosion, or derailment; end fittings secure; drum winding neat | □ Pass □ Fail | ||

| Function Test | No-load operation is smooth; brake slipping distance ≤ V/100; limit switches act accurately; buttons respond sensitively | □ Pass □ Fail | ||

| Working Environment | Rail and area clear of obstacles; ambient temperature -25℃~40℃; no corrosive gases; humidity ≤85% | □ Pass □ Fail | ||

| 2. Safety Operation Confirmation | Operation Compliance | No overload (≤125% rated load), no side-pull lifting, no simultaneous reverse button operation | □ Pass □ Fail | |

| Limit Switch Usage | Limit switches are not used as regular travel switches | □ Pass □ Fail | ||

| Post-Operation Status | No prolonged load suspension; main power supply is shut off after operation | □ Pass □ Fail | ||

| 10-20 Ton Models | If motor thermal protection trips, confirm automatic recovery after natural cooling | □ Pass □ N/A |

| System | Maintenance Item | Standard/Requirement | Result | Maintenance Record |

| 1. Lubrication | Gearbox Oil | Check level & cleanliness after first 500h, then every 3 months | □ Pass □ Fail | Level:______ Status:______ |

| Chain Lubrication | Apply special grease monthly; increase frequency in dusty environments; use tools | □ Pass □ Fail | Date:__________ | |

| Bearings & Gears | Replenish grease quarterly; monitor temperature rise & insulation resistance | □ Pass □ Fail | Amount:______ Temp Rise:______ | |

| 2. Electrical System | Cables/Switches/Grounding | Monthly check for damage, aging, leakage; reliable grounding | □ Pass □ Fail | Findings:__________ |

| Control Box Test | Buttons respond sensitively; no sticking or malfunction | □ Pass □ Fail | □ Tested □ Needs repair | |

| Motor & Gearbox | No abnormal noise; normal temperature; no oil leakage; change oil as scheduled | □ Pass □ Fail | Noise:□Normal □Abnormal Seal:□Intact □Leaking | |

| 3. Safety Devices | Limit Switches | Accurate positioning; hook-to-drum distance >50mm(>10t:120mm); ≥2 rope wraps remaining | □ Pass □ Fail | Upper Limit:mm Wraps: |

| Brake | Lining surface even; braking performance meets standard | □ Pass □ Fail | Performance:□Good □Needs adjust | |

| Protection Devices | Reliable overload & short-circuit protection | □ Pass □ Fail | □ Functional □ Faulty |

Daily and Regular Maintenance: Clean the equipment surface daily; check the hook's rotation flexibility weekly. Perform minor repairs quarterly, including fastener condition checks and lubrication maintenance; conduct a comprehensive overhaul annually, promptly replacing chains, brake pads, and other components that have reached their wear limits.

Professional Inspection Requirements: Certified professionals shall conduct regular inspections and maintain detailed documentation of all maintenance activities, including service intervals, specific procedures performed, and operational outcomes. This comprehensive maintenance record provides essential data for effective equipment management and systematic fault analysis.

Operators must immediately stop equipment and disconnect all power sources upon detecting operational abnormalities such as motor overheating or brake failure. Cause investigation may only commence after the equipment has reached a complete standstill and cooled to ambient temperature.

All maintenance work must be carried out only after the power is disconnected and a tag is attached. Operating the equipment under load is strictly prohibited.

Replacement of wire ropes shall strictly comply with GB/T5972-1986. Immediate replacement is mandatory upon detection of broken wires or wear exceeding specified limits. All installation procedures must conform to established technical specifications.

When operating outdoors, rainproof devices should be provided to prevent electrical components from being damaged by moisture.

Operating in humid, high-temperature, or corrosive environments is strictly prohibited.

Lifting molten metal, toxic substances, and flammable and explosive hazardous materials is prohibited.

Before long-term shutdown, the equipment must be cleaned, coated with anti-rust grease, and run unloaded for 3 minutes.

The storage area should be kept dry and well-ventilated to prevent components from getting damp or corroded.

1. Equipment Fails to Start

Check the main power supply connection to ensure normal power supply.

Inspect the control circuit to rule out wiring damage or loose connections.

2. Abnormal Operating Speed

Check the lubrication of transmission components and replenish the specified lubricant as needed.

Test motor performance and electrical contact condition to rule out electrical faults.

3. Abnormal Operating Noise

Diagnose the wear of the transmission mechanism (gears, bearings) and replace damaged parts promptly.

Check the lubrication and wear of the wire rope/chain, maintain proper lubrication, and replace any defective parts.

4. Positioning Failure

Verify the accuracy of the limit switch and adjust or replace any malfunctioning switches.

5. Load Uncontrolled

Inspect the braking system and adjust the brake clearance or replace worn brake pads.

6. Overload Trip

Confirm that the actual load does not exceed the rated load.

Verify the parameters of the overload protection device and recalibrate it according to the manufacturer's specifications.

Ensuring Operational Safety: Regularly inspecting key safety devices (brakes, limit switches, overload protection) effectively prevents accidents such as falling objects and loss of control, ensuring the safety of personnel and equipment.

Extending Equipment Lifespan: Systematic lubrication, tightening, and component replacement reduce structural wear and metal fatigue, delaying equipment aging and increasing average service life.

Maintaining Stable Performance: Regular calibration and adjustment maintain lifting accuracy, braking performance, and operational stability, ensuring the equipment continuously meets rated operating requirements.

Improving Work Efficiency: Reducing work interruptions due to sudden malfunctions ensures production rhythm while maintaining optimal equipment operating condition, ensuring smooth and efficient lifting processes.

Daily maintenance of electric hoists is a systematic project. To ensure long-term stable operation, companies should develop targeted maintenance plans based on specific models and operating conditions, focusing on standardized operation, regular inspections, timely lubrication, and professional repairs. Establish comprehensive maintenance records and assign qualified personnel to implement standardized procedures. This ensures full traceability and verifiability throughout all operational stages, effectively enhancing equipment reliability, extending service life, and guaranteeing production safety.

For any questions regarding service or maintenance, our service team is always ready to support you. For information on high-quality, durable electric hoist products, please contact us for the perfect lifting solutions!

Огноо:

Огноо:

Хүсэлт илгээх