Gru a cavalletto

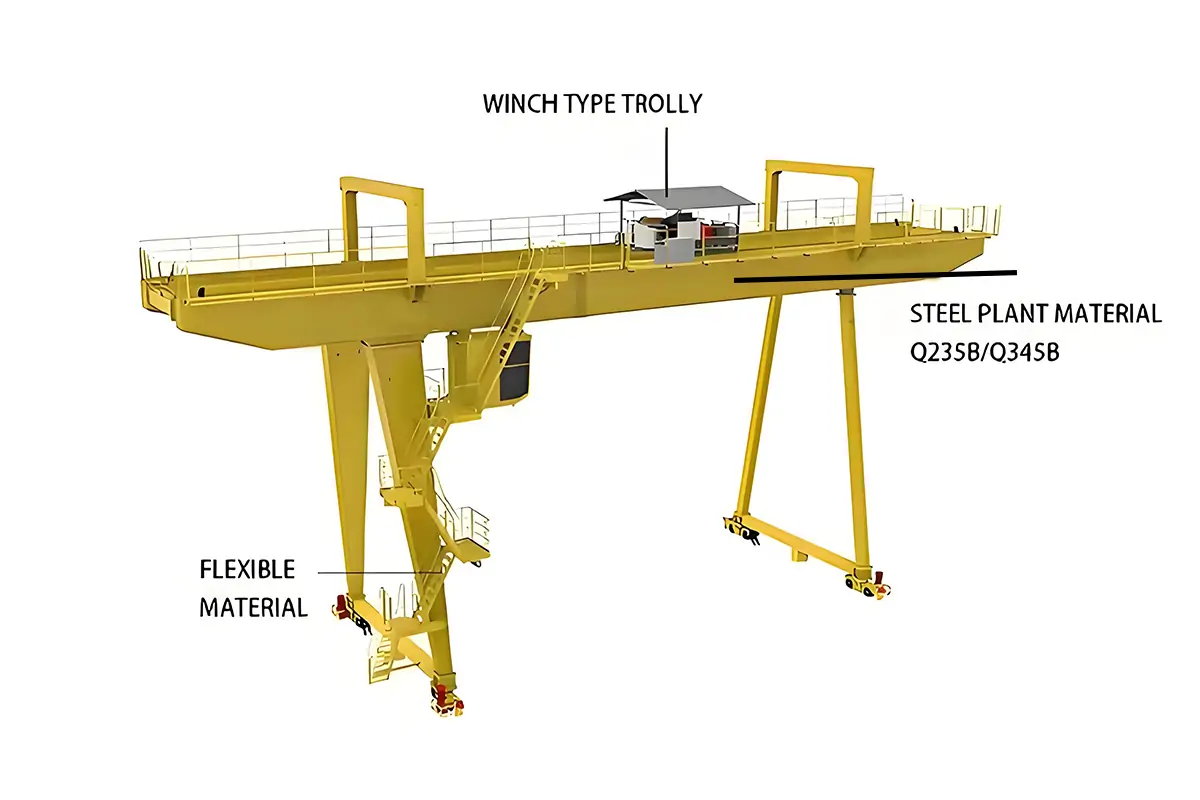

The European Double Girder Gantry Crane is a modern material handling solution designed for medium to heavy duty industrial applications. Adopting advanced European design concepts and manufacturing standards, the European Double Girder Gantry Crane offers significant advantages in terms of structural strength, operational efficiency and space utilization.

Compared with the ordinary double girder gantry crane, its main features are the use of European standards, a hardened surface of the reducer, a three-in-one drive, and PLC+frequency conversion control technology. This design comprehensively improves the product performance. At the same time, the weight of the crane is reduced by more than 15%, and the wheel pressure is reduced by 10-20%. It is suitable for general handling and lifting operations in open warehouses or along railroad tracks. It can also be equipped with a variety of lifting equipment for special operations.

| Differences | European double-beam gantry crane | Traditional double-beam gantry crane |

|---|---|---|

| Structural weight | Lightweight design (15-30% lighter) | Traditional box-beam structure |

| Operation energy consumption | Energy saving of more than 30% | Conventional energy consumption level |

| Altezza di sollevamento | Height optimization and 20% improvement | Fixed clearance requirement |

| Control accuracy | ±1mm positioning accuracy | ±10mm conventional accuracy |

| Maintenance cost | Maintenance-free bearings + centralized lubrication system | Conventional lubrication requirements |

| Service life | Design life of 25 years (FEM standard) | Generally 15-20 years |

| Ease of installation | Generally, 15-20 years | Large on-site welding workload |

European double beam gantry cranes are widely applicable in material handling situations. Usually, it is in steel metallurgy, hydro-power, aerospace, ships, automobiles, coal, petrochemicals, etc. And European gantry cranes can not only achieve bi-directional movement but also easily raise or lower heavy objects. It requires special technical methods to ensure operational safety in explosive, flammable, or corrosive environments.

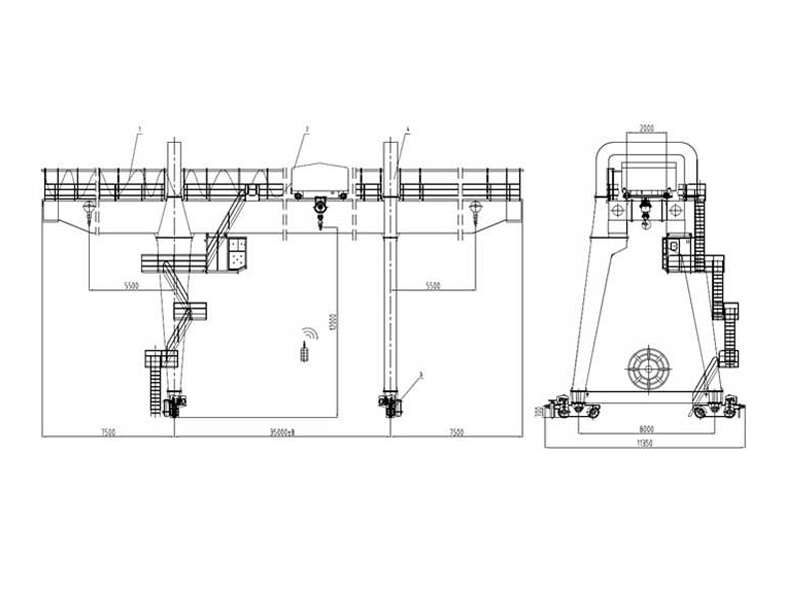

European double girder gantry cranes are designed and manufactured by advanced European FEM standards and consist of two main girders, an end beam system, a hoisting trolley, a control system, a cab, and so on. The following are the basic functional characteristics of the main components:

| Nome del prodotto | European double-beam gantry crane |

|---|---|

| Apparecchiature di sollevamento | Carrello elettrico |

| Capacità (T): | ≥5 tonnellate |

| Campata (M): | 10,5---31,5 metri |

| Altezza di sollevamento (M): | 6---12 metri |

| Lavoro di servizio: | M5 |

| Velocità di sollevamento (m/min): | 2---20 |

| Velocità della gru (m/min) | 3---30 |

| Temperatura di lavoro (℃)) | -20--40 |

| Fonte di alimentazione | Trifase A.C. 380V 50HZ |

| Metodo operativo | Controllo a terra+telecomando |

Weihua is a well-known manufacturer and supplier of European Double Girder Gantry Crane in China. We provide customized engineering solutions including turnkey support from design, FEM certified manufacturing to installation and maintenance. CE certification, ISO 9001 quality assurance, and after-sales technical support.

Weihua's European double girder gantry cranes are designed according to the highest FEM standards for industries such as steel manufacturing, port logistics, wind energy and large-scale manufacturing. They are available in capacities from 5T to 320T and can be equipped with optional double hoists, automatic positioning, and specialized lifting accessories. Interested in a customized European Gantry Crane solution? contact our engineering team for a free consultation and project assessment.

Non esitate a lasciare un messaggio. Risponderemo entro 24 ore.

Invia la richiesta