Noticias

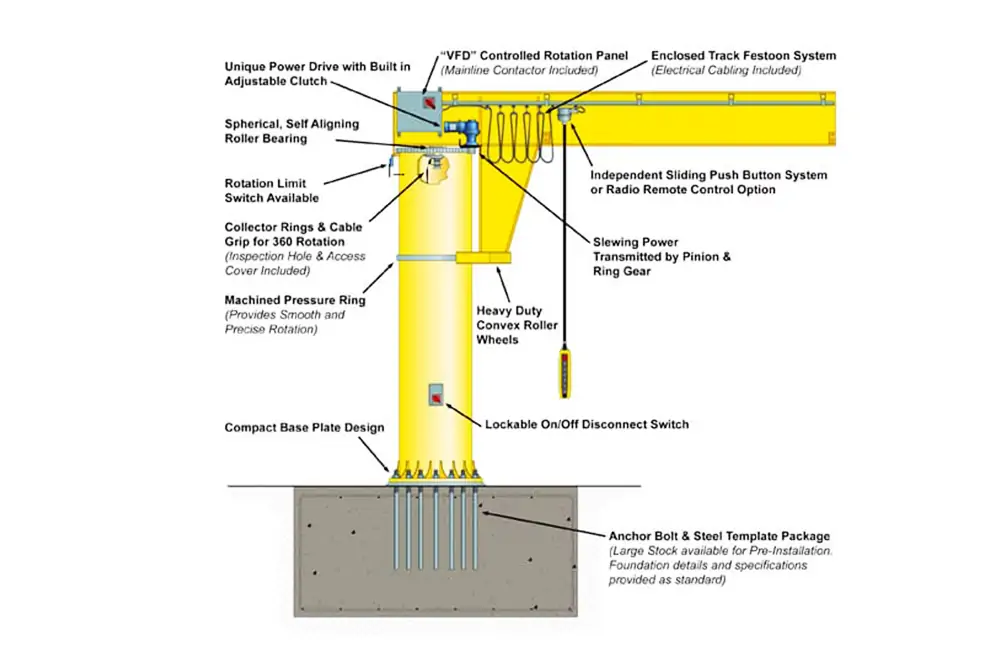

A pillar jib crane is a freestanding lifting device widely used in workshops, warehouses, and production lines for material handling. To ensure safe operation and long-term stability, the foundation of a pillar jib crane is one of the most critical components in the entire system. A well-designed and properly installed foundation not only supports the crane's load but also resists tilting, vibration, and ground stress over time.

In this article, we’ll explore everything you need to know about pillar jib crane foundations, including concrete foundation, design, and installation methods. If you're planning to install a pillar jib crane, keep reading to ensure your foundation meets safety and efficiency standards.

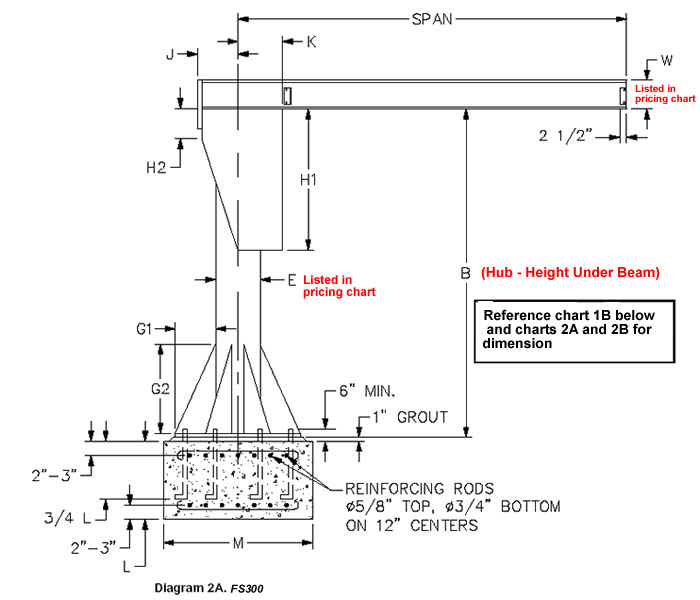

Generally, the base is designed using finite element analysis (FEA) or structural design software, in line with local building codes. A typical design may involve a foundation block of 800mm–1200mm depth with heavy-duty anchor bolts fixed into the rebar cage.

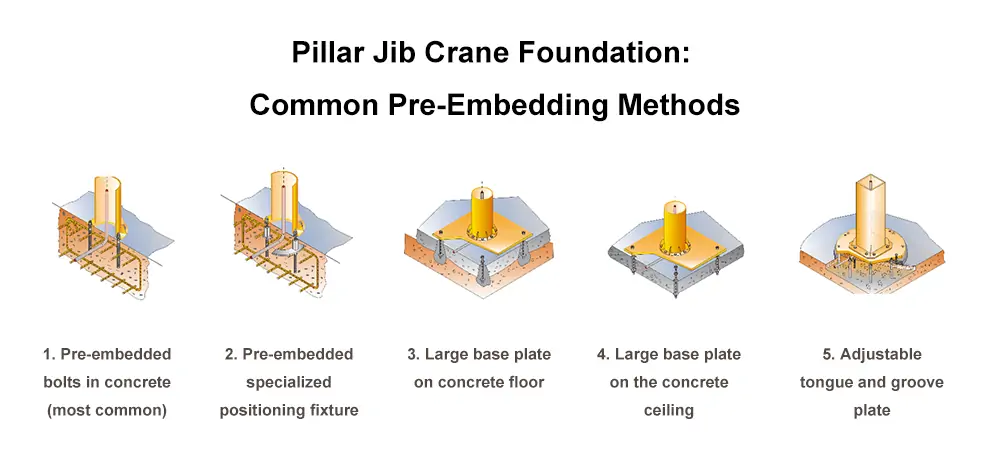

The installation method of pillar jib cranes should be selected according to the type of foundation and site conditions. Mainly, there are two forms of pre-buried installation and surface fixed installation, which can be subdivided into the following five installation methods:

Pre-embedded bolts in the concrete foundation first, when the concrete is cured, the base of the jib crane is bolted, and the verticality of the jib crane is corrected.

Minimize post-installation vertical alignment adjustments by using a special positioning jig embedded in the floor bolts.

Secure the square base plate to the floor using chemical anchors, level, and tighten.

Then bolt the crane column to the base plate, taking care to adjust the level of the large base plate; this method is usually applied to standard concrete floors.

Similar to the floor mounting method. Firstly, use the long threaded rod to fix the base plate on the ceiling (usually a concrete floor slab), and secondly, connect the cantilever crane column with the bolt holes on the large base plate. This method is suitable for small tonnage cranes with high ceiling strength.

For jib cranes requiring exact positioning or handling dynamic loads, an adjustable dowel system is employed. This method utilizes countersunk dowel plates with high-precision imported dowel pins to ensure secure alignment under operational stresses.

Each method has its applicability, depending on load capacity, foundation type, and installation conditions. Proper alignment and anchoring ensure stability and safety.

Jib crane foundation installation typically follows these steps:

For a 1-ton pillar jib crane, a common foundation configuration might include:

A reliable free standing jib crane foundation ensures the safe and efficient operation of your lifting system. From concrete type to design drawing and specification details, every step is vital to long-term performance and safety. If you have technical questions or need assistance with foundation design and installation, feel free to contact Weihua's technical support team. We’re here to provide free expert guidance and help you select or customize the right foundation solution for your jib crane project.

Enviar solicitud