الرافعات العلوية

The KBK crane system is a modular, lightweight crane system that can be suspended from the roof or superstructure of a building without additional support, making it easy and inexpensive to install. The system is suitable for use in localized or whole workshop areas and is stable and reliable. Its self-supporting design enables it to perform frequent overhead material handling tasks efficiently. It can be installed on 15 cm-thick reinforced concrete floors, thereby avoiding additional pressure on the roof structure. The prefabricated standardized module design allows the system to be flexibly expanded according to production requirements. It helps companies optimize space utilization, reduce energy consumption, and increase productivity.

The KBK crane system supports manual, semi-automatic, and fully automatic operation and is widely used in high-precision material handling scenarios in machinery manufacturing, electronics, warehousing, and logistics industries. Its lifting capacity ranges from 0.25 to 3 tons, which is especially suitable for modern production conveyor lines and can realize linear round-trip, circular transport, and other material handling modes. The system's flexible operation direction supports seamless switching from single-line to multi-line and circular tracks. It is widely applicable to material transportation in various industries to meet the demand for efficient and precise transportation.

KBK crane system offers a wide range of models, including KBK monorail suspension cranes, single girder, double girder, etc., to meet the diversified needs of different industries. Whether for efficient material handling or precision assembly, our systems provide you with flexible and reliable solutions. Feel free to contact our professional team to customize the most suitable crane system for you, helping to improve productivity and optimize workflow!

Flexible KBK crane system

Rigid KBK Crane System

D Type KBK Crane System

D Type KBK Crane System: With standardized components, it can be combined with loop, fork, and mesh lines to support bi-directional material conveying. Each trolley is independently driven by electric power, not limited by length, with a conveying capacity of 3000 kg, suitable for flexible material transfer needs.

Flexible KBK Crane System: It consists of standard linear rail and auxiliary parts. The trolleys at both ends of the main beam can run on the vertical rail, and it is equipped with chain hoists, which are suitable for transporting plane material. Double-track design enhances the load-carrying capacity, suitable for large-span heavy material lifting.

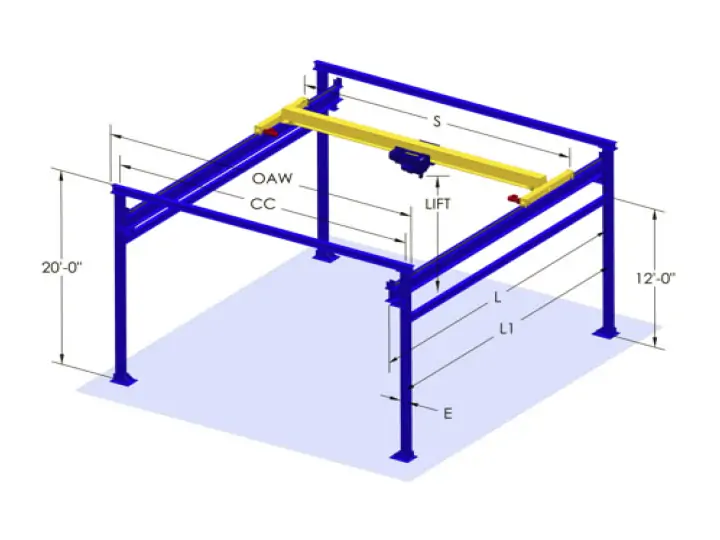

Rigid KBK Crane System: It adopts a rigid truss double main girder structure, with a lifting capacity of 0.25~5 tons, and increased hook height, suitable for space-restricted places. Independently installed on the ground, with an overhead crane or gantry crane cross operation, flexible expansion, low cost, KBK crane adapts to a variety of working environments.

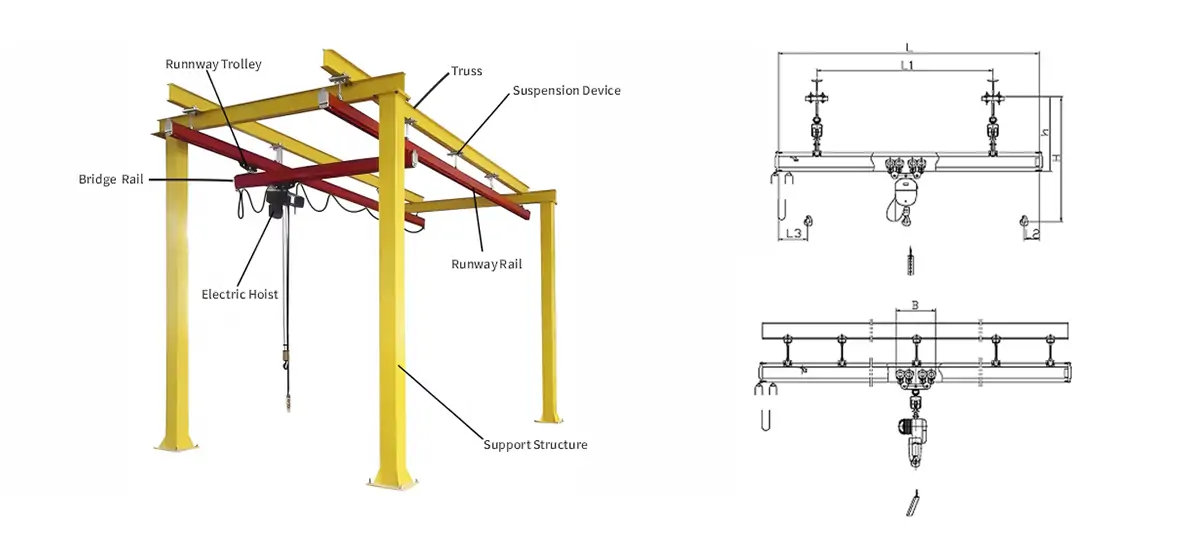

The KBK crane system consists of standardized modules, mainly including rails, suspension devices, traveling vehicles, and various functional components. The lifting device is usually an electric chain hoist, but other tools, such as manipulators or welding torches, can also be suspended and used as tool rails as required. The lifting capacity of the system ranges from 250 kg to 3,000 kg, which meets the material handling requirements of different working conditions. All components comply with KBK standards, and the entire KBK crane system is compatible, flexible, and efficient for high-precision operation in a wide range of industrial scenarios.

| Work Load(ton) | ≤3 ton |

| امتداد(م) | 0.7-12 m |

| ارتفاع الرفع(م) | 3 - 12 m |

| مزود الطاقة | 380V,50HZ,3-Phase or Customized |

| طريقة التحكم | Pendant Control, Remote Control, Cabinet Control |

| Travelling mode | manual or electric |

KBK crane is fast, stable, and highly flexible. Whether it is a monorail, single girder, or double girder KBK crane system, it can be flexibly configured according to the actual needs and adapted to diversified working environments and operational requirements. It is widely used in automobile manufacturing, the electronics industry, food processing, pharmaceutical manufacturing, warehousing and logistics, machinery manufacturing, and textile and metal processing industries. Specific application scenarios are as follows:

Automotive manufacturing: In automotive production lines, KBK rail cranes are used for the transportation, assembly, and inspection of parts.

Electronics manufacturing: KBK crane systems are equipped with a precision control system, which can stably transport and position electronic components to avoid damage during transportation.

Food processing: KBK crane systems are made of clean materials that meet hygiene standards. Suitable for the transportation and storage of food raw materials and finished products, as well as for material handling in production lines.

Pharmaceutical manufacturing: In pharmaceutical manufacturing, KBK crane systems are used for the transportation and packaging of pharmaceutical raw materials and finished products.

Warehouse logistics: For loading and unloading, sorting, and storage of goods.

As a leading global lifting equipment manufacturer, Weihua Global specializes in providing high-performance and reliable KBK Crane Systems. With years of industry experience and technology accumulation, we focus on providing customized solutions for our customers, covering a wide range of KBK monorail, single girder, double girder, industrial jib crane, and gantry cranes to meet the diversified needs of automotive manufacturing, electronics industry, food processing, warehousing and logistics, and so on. Contact our professional team today for exclusive solutions!

لا تتردد في ترك رسالة. وسوف نقوم بالرد خلال 24 ساعة.

إرسال الطلب