Gantry Cranes

BMH single girder semi gantry crane is a light-duty gantry crane running on rails, which can be used with CD1, MD, HC, and other types of electric hoists. Its lifting capacity ranges from 2-20 tons, span 6-20 meters, applicable to the working environment of -20°C to +40°C, widely used in factories, warehouses, yards, and other common places for lifting goods. The crane is designed to be flexible, with a cantileverless or cantilevered structure according to demand, with outriggers in the form of a package box and rectangular tube, and supporting railed or rail-less operation to meet diversified operational needs.

BMH single girder semi gantry cranes adopt modular and parametric design, compact structure, and are easy to install and maintain. The hoisting mechanism is equipped with a stable, safe, and reliable wire rope electric hoist, and the trolley running mechanism adopts a vertical variable speed or three-in-one driving device to ensure smooth and efficient operation. Flexible and diversified operation modes, supporting handle operation, remote control operation, driver's room operation, or a combination thereof, can adapt to the needs of different working conditions.

In addition, the semi-gantry crane is equipped with a conventional speed control system and multiple safety devices to ensure safe and reliable operation, which is the ideal choice for efficient material handling.

Single girder semi gantry cranes are widely used in applications requiring medium to small-scale lifting operations due to their compact structure, high adaptability, and relatively low cost. They are particularly suitable for environments with limited space but requiring efficient material handling. The following are the applications of single-girder semi-gantry cranes across various industries:

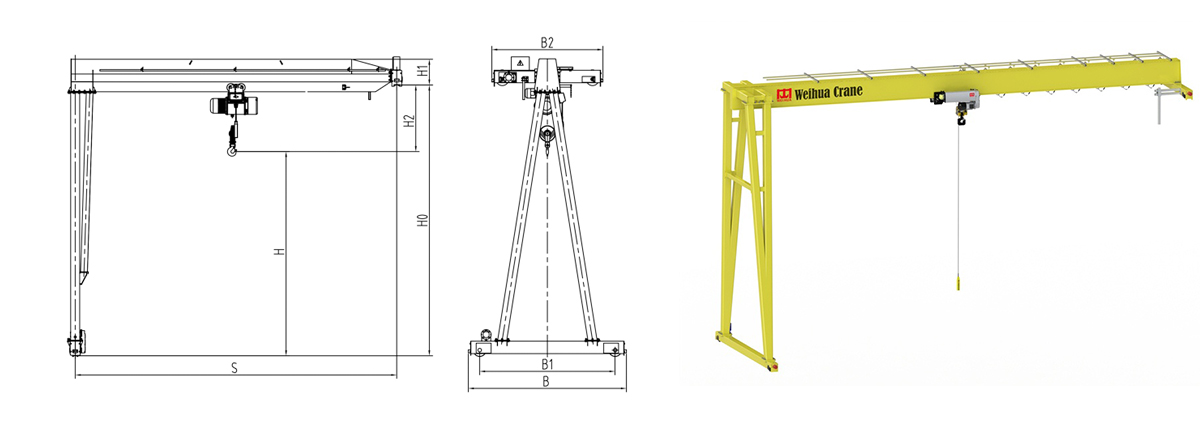

BMH single girder semi gantry crane is a lifting equipment with single side outrigger design, which is mainly divided into two structural forms: box girder type and truss type. Its core components include a bridge, trolley running mechanism, and hoisting mechanism.

The trolley running mechanism is composed of a running motor, a reducer, and a wheel set. The trolley is mounted on the I-beam track under the main beam by suspension, and can move smoothly along the main beam in the transverse direction to realize accurate positioning.

The lifting mechanism consists of key components such as the reel, the reel shell, the lifting motor, the reducer, the wire rope, the hook set, and the lifting capacity limiter.

| Span(rail to rail center) | 6m~20 or customize | ||||

| Cantilevers | According to your demand, but not more than 1/3 of span | ||||

| Lifting height | 6m~30m | ||||

| Capacity | 3t, 5t | 10t | 15t, 16t | 20t, 25t | 30t, 32t |

| Lifting speed(m/min) | 8, 8/0.8 | 7/0.7 | 3.5 | 4, 4/0.4 | 3, 3/0.3 |

| 3.5/0.35 | |||||

| Cross travelling speed(m/min) | 10 or 20 | ||||

| Long travelling speed(m/min) | 20, 30 | ||||

| Duty Class | A3/A5 | ||||

| Power source | Pendant pushbutton control, cabin control, or remote control | ||||

| Power supply mode | Cable reel / Bus bar | ||||

| Control model | Pendant pushbutton control, cabin control or remote control | ||||

As a leading Semi-Gantry Crane manufacturer, Weihua Crane specializes in high-performance single girder semi-gantry cranes designed for versatile industrial applications. Our cranes combine the space-saving benefits of gantry systems with the cost efficiency of single girder designs, making them ideal for workshops, warehouses, and outdoor loading areas with limited runway support requirements.

Please feel free to leave a message. We will reply in 24 hours.

Submit Request