Industry News

In industrial and commercial material handling, selecting the appropriate crane type is crucial for improving operational efficiency. While both jib cranes and gantry cranes are widely used for lifting heavy objects, they differ significantly in structural form, movement method, lifting capacity, and applicable scenarios. This article aims to compare and analyze the main differences between these two types of cranes and summarize the key factors to consider when selecting one for specific applications, helping you choose the optimal lifting solution.

A jib crane is a versatile and cost-effective lifting solution designed for material handling in confined spaces. Its core structure is a horizontal boom that rotates around a column, enabling efficient lifting, moving, and precise positioning of goods within a fixed radius. It is suitable for applications with concentrated work areas and high positioning accuracy requirements. If you want to learn the workings of Jib Work, check out this article: How Does a Jib Crane Work? Structure, Operation, and Uses

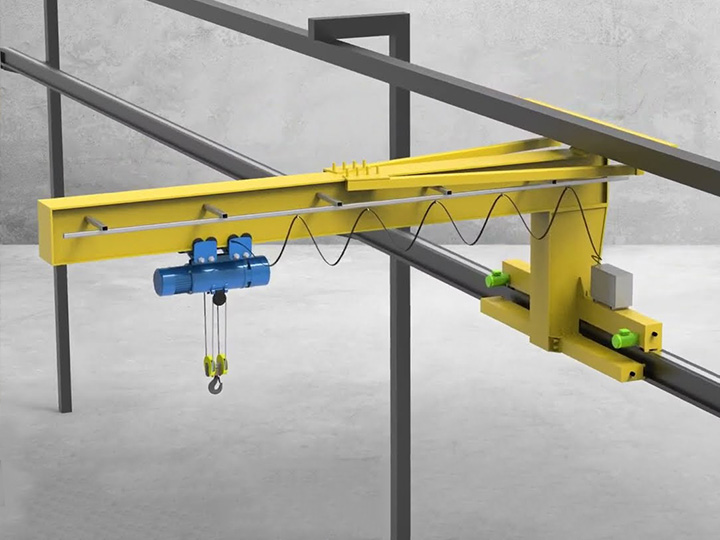

A gantry crane is supported by a horizontal bridge and two columns, which can be mounted on wheels or rails for movement. The bridge can move along the length of the columns, thus covering a wider area. The gantry crane can move along a fixed path or be repositioned within the plant area. It can be mounted on wheels or rails, offering greater mobility and flexibility compared to jib cranes.

1. Wall-mounted cantilever crane

Features: Mounted on a wall or vertical support structure, can rotate 180 degrees, and is fixed in place.

Advantages: Space-saving, can be installed on existing structures, and economical.

Applications: Used for localized material handling in workshops, manufacturing plants, and assembly lines.

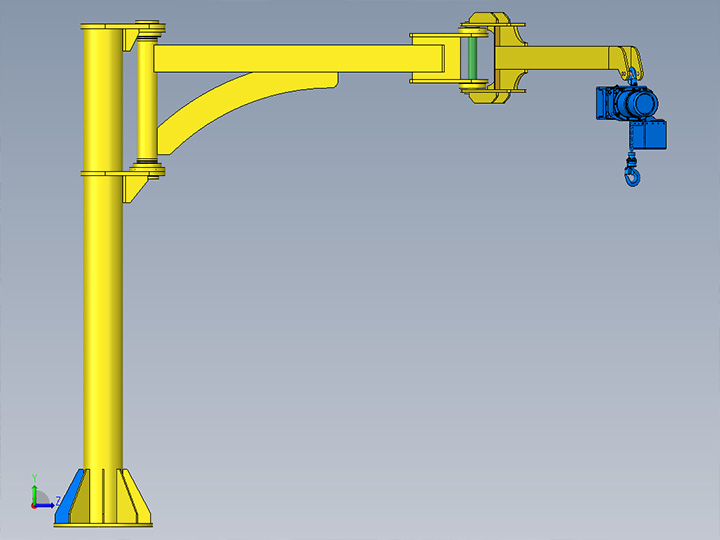

2. Column-Mounted Cantilever Crane

Features: Mounted on an independent column, 360-degree rotation, self-supporting.

Advantages: Wide coverage, versatile applications, heavy-duty capacity.

Applications: Commonly used in large manufacturing and industrial environments requiring multi-functional material handling.

Features: Mobility to different locations, usually equipped with casters, rather than a fixed type.

Advantages: High mobility, versatile, and easily relocated as needed.

Applications: Used for temporary material handling in small workshops, warehouses, and construction sites.

4. Articulated boom crane/telescopic boom crane

Features: Telescopic boom, adjustable extension range, multiple configurations.

Advantages: Flexible operating range, adaptable to changing working conditions.

Wide applications: Suitable for material handling in various environments, such as freight terminals and outdoor construction sites.

1. MH Box-Type Single Girder Gantry Crane

Features: Utilizes a box-type or I-beam steel structure, lightweight, and easy to install and maintain.

Advantages: Relatively low manufacturing cost, suitable for small to medium tonnage lifting needs, economical and practical.

Wide Range of Applications: Suitable for material handling in various environments, especially in warehouses, factories, and docks.

2. BMH Single-Girder Semi-Gantry Crane

Features: Features a single-side outrigger design, robust structure, and easy installation.

Advantages: Flexible design, supports rail-mounted or railless operation, meeting diverse operational needs.

Wide Applications: Widely used for cargo lifting operations in factories, warehouses, storage yards, and other locations.

3. L-type Single-Girder Gantry Crane

Features: Designed specifically for modern construction needs, highly efficient in operation, and adaptable to various working environments.

Advantages: The main beam adopts a single-beam staggered rail design, providing a large lifting space and strong span load-bearing capacity.

Wide Applications: Suitable for loading and unloading goods, yard goods, and bulk goods outdoors without load-bearing beams.

Features: Equipped with braked casters for flexible movement and easy adaptation to various working environments.

Advantages: Compact structure, small size, flexible movement, easy assembly and maintenance.

Wide Applications: Designed for garages, workshops, warehouses, and workstations for lifting and handling light materials.

Understanding the differences between jib cranes and gantry cranes is crucial for selecting the right crane to meet operational needs. Below is a detailed comparison based on structure, mobility, application area, and lifting capacity.

| Factor | Jib Crane | Gantry Crane |

| Structure | Single horizontal arm on a vertical support or wall | Bridge supported by legs; can cover large spans |

| Mobility | Fixed to a base, limited horizontal rotation | Freestanding with track or wheels; wide area coverage |

| Load Capacity | Typically lower, ranging from 1 to 5 tons | Higher capacities; can lift heavy loads up to hundreds of tons |

| Applications | Indoor, localized lifting within workstations or cells | Both indoor and outdoor applications; ideal for heavy lifting |

| Types | Free-standing, wall-mounted, articulating | Full gantry, semi-gantry, portable, RMG |

| Flexibility | Limited movement; fixed area coverage | High flexibility; spans large areas and can be repositioned |

Jib cranes are economical and efficient local material handling equipment, commonly found in workshops, warehouses, and maintenance stations. They are suitable for frequent lifting and precise positioning under medium to low loads.

High space utilization: Compact structure, suitable for facilities with limited space or small footprints.

Low cost: Simple structure, low material usage, resulting in lower purchase and installation costs.

Easy installation: Can be mounted against walls or columns, requiring minimal site modifications.

Flexible operation: The boom can rotate, facilitating quick and precise positioning within a fixed radius.

Limited operating range: The boom length determines the coverage radius, limiting large-scale movement.

Lower lifting capacity: Only suitable for lighter loads, not for heavy lifting tasks.

Limited application scenarios: Unsuitable for material handling across areas or along complex routes.

Gantry cranes are heavy-duty lifting equipment widely used in shipbuilding, steelmaking, construction, and large warehousing, capable of spanning and covering vast work areas.

Advantages

High Lifting Capacity:Handles large and heavy loads, meeting the needs of heavy industry.

Wide Coverage:The cable tray spans the work area, supporting large-area material handling.

High Adaptability: Can be used indoors and outdoors; some models are disassembled and reassembled, offering high flexibility.

Comprehensive Functionality:Suitable for various complex lifting tasks, supporting large-tonnage operations.

Disadvantages

Large Footprint:Requires significant space and clearance.

High Initial Investment:Complex structure; manufacturing and installation costs are significantly higher than cantilever cranes.

High Maintenance Costs: More complex mechanical systems; higher requirements for daily maintenance and repair.

Making a reasonable decision between a cantilever crane and a gantry crane hinges on a comprehensive evaluation of factors such as load capacity, space availability, mobility, and installation conditions. Here are four key aspects to consider when selecting a model:

Jib crane: Suitable for light to medium loads (typically several hundred kilograms to several tons), ideal for repetitive, localized lifting tasks, such as loading and unloading on production lines or moving materials between workstations.

Gantry crane: High load-bearing capacity, capable of handling heavy loads (often tens of tons or more), widely used in shipbuilding, heavy manufacturing, and large construction sites, among other heavy-duty operations.

Jib crane: Compact structure, suitable for installation on walls or columns, occupying minimal ground space, especially suitable for narrow spaces such as workshops and assembly areas.

Gantry crane: Large span, capable of covering a wide area, suitable for large-span indoor factories or outdoor sites, but requires a certain clearance height.

Jib crane: Generally fixed installation, serving fixed workstations, offering high stability.

Gantry cranes: Flexible movement; full-gantry models can run along tracks, semi-gantry models can be moved with ground wheels, and portable models can be quickly relocated, adapting to dynamic operation needs.

Jib crane: Easy to install, often fixed to existing walls or ground structures, requiring minimal modification and a short installation period.

Gantry cranes: Usually require pre-installed tracks or reinforced foundations, resulting in higher installation complexity and cost, but providing the necessary support for their high lifting capacity and working range.

Jib cranes and gantry cranes each have their advantages and are suitable for different operating scenarios. Cantilever cranes have a compact structure and perform better in spaces with limited space; while gantry cranes, with their high lifting capacity and wide coverage area, are capable of handling heavy-duty, large-area lifting tasks. Whether choosing a jib crane or a gantry crane, selecting the appropriate model is crucial to ensuring operational efficiency, safety, and productivity.

Weihua Cranes can provide you with professional customized solutions to meet diverse industry lifting needs. Welcome to contact us!

Submit Request