News

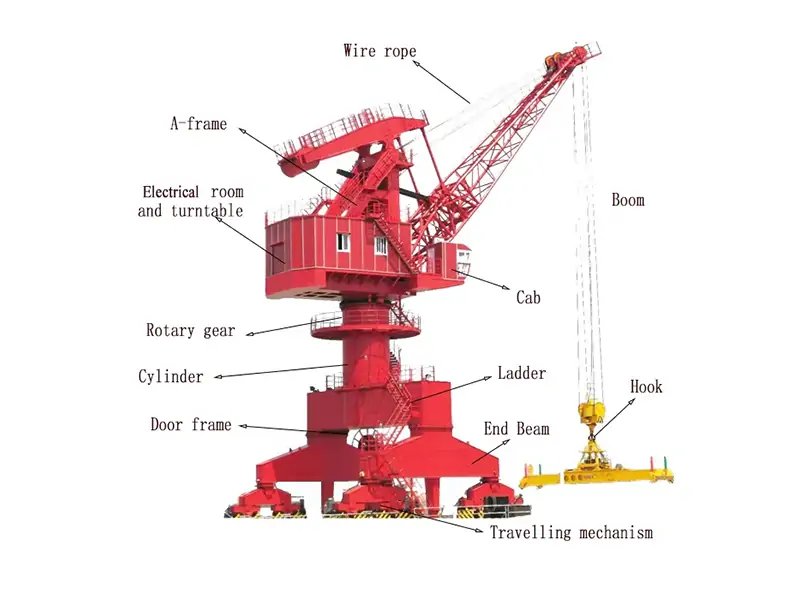

The Portal Boom Crane is a heavy-duty lifting device widely used in ports, shipyards, and large industrial facilities. Its unique portal frame structure and rotatable boom design enable efficient operation even in confined spaces. Regular maintenance is essential to ensure the long-term stable operation of the equipment. This article will provide a detailed overview of the structural components, daily inspection points, and maintenance techniques for the Portal Boom Crane, helping you extend the equipment's lifespan and enhance operational safety.

The Portal Boom Crane primarily consists of the following core components:

| Category | Component | Inspection/Maintenance Task | Frequency | Action if Issue Found |

|---|---|---|---|---|

| Mechanical Components | Wire Ropes & Pulleys | Check for wear, broken wires, and lubrication | Daily | Top up oil, repair leaks, and replace faulty valves |

| Hydraulic System | Inspect oil levels, leaks, and valve operation | Daily | Apply the recommended lubricant | |

| Bolts & Connectors | Tighten loose bolts and fasteners | Weekly | Re-torque or replace missing bolts | |

| Electrical System | Cables & Terminals | Check for fraying, corrosion, or poor contact | Daily | Repair/replace damaged cables, clean terminals |

| Limit Switches & Sensors | Test sensitivity and functionality | Weekly | Calibrate or replace faulty sensors | |

| Motor & Brake | Monitor temperature and braking response | Daily | Service brakes, check motor cooling | |

| Lubrication & Corrosion | Bearings, Gears, Hinges | Adjust counterweights, inspect the structure | Weekly/Monthly | Re-lubricate, replace worn parts |

| Metal Surfaces | Remove rust and apply anti-corrosion paint | Monthly | Sand, prime, and repaint affected areas | |

| Operational Testing | No-Load Test | Run the crane without a load, check for unusual noise/vibration | After maintenance | Investigate and fix abnormalities |

| Load Test | Test under safe working load, monitor stability | After major repairs | Adjust counterweights, inspect structure |

The efficient operation of Portal Boom Cranes relies on scientific maintenance management. By regularly inspecting mechanical and electrical systems and ensuring proper lubrication and corrosion prevention, the risk of failure can be significantly reduced, and the service life of the equipment extended.

If you require a more specialized Portal Boom Crane maintenance plan or customized technical services, please contact us! We will provide you with comprehensive technical consulting and optimized solutions.

Date:

Submit Request