Industry News

Jib cranes are one of the most versatile and efficient solutions for lifting and transporting heavy materials, renowned for their simple structure, high efficiency, and strong adaptability. This article introduces five types of jib cranes manufactured by Weihua, including their structural features, working principles, advantages, application areas, and maintenance tips. Whether you are purchasing a jib crane for the first time or looking to upgrade your existing equipment, this article will provide you with comprehensive guidance to help you make the best choice.

A jib crane is a type of crane specifically designed for moving materials and equipment within a defined area. It consists of a horizontal boom and a vertical mast or column. The boom can rotate horizontally, allowing the lifting equipment and load to move in a circular or semi-circular motion. This high degree of mobility makes it ideal for lifting and moving heavy objects in areas with limited space, such as warehouses, manufacturing plants, and construction sites.

According to the different installation methods and structural characteristics, there are five types of jib cranes: floor-mounted jib cranes, mobile jib cranes, wall jib cranes, wall traveling jib cranes, and articulating jib cranes. Below are the characteristics of each type of jib crane:

Floor-mounted jib cranes consist of a column and a cantilever. The column is fixed to the ground or foundation, supporting the rotatable boom. Lifting capacities range from 0.25 to 5 tons, and spans can reach 8 meters. They can rotate from 180°~360°, making them ideal for precise, repetitive lifting operations in confined spaces. Commonly used in workshops, assembly lines, and loading/unloading areas, they provide cost-effective and space-saving material handling solutions.

Mobile jib cranes use high-strength casters or tracked wheels to move easily between different workstations. Their unique slewing jib design, combined with an electric chain hoist or electric wire rope hoist, enables 360° flexible operation. These cranes fit particularly well in space-constrained areas such as low-ceiling environments and warehouses, where traditional mobile cranes cannot be installed. As a result, they serve as an ideal solution for workshop equipment installation, goods handling, and similar operations.

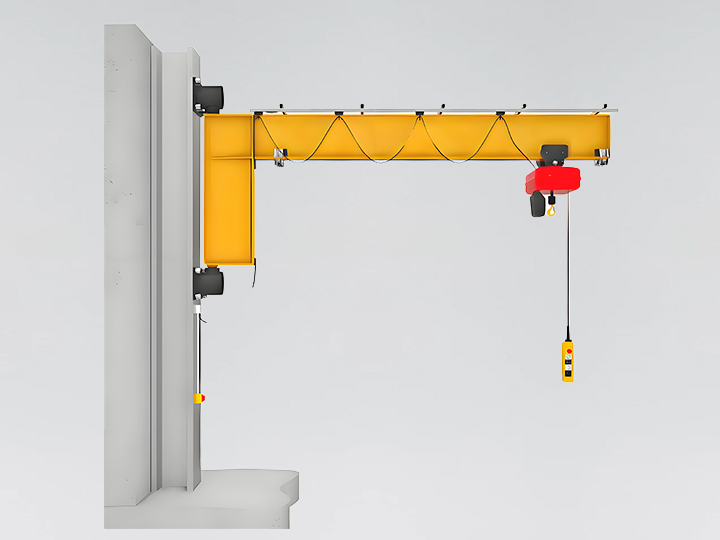

Wall-mounted jib cranes provide a compact lifting solution that installs directly on walls or columns. This wall-mounted design saves valuable floor space, making these cranes particularly suitable for space-constrained environments like small workshops, warehouse corridors, and equipment-dense areas.Their modular, parametric structural design ensures a robust build with excellent stability and reliability. Users benefit from flexible operation, ease of maintenance, and efficient space utilization.

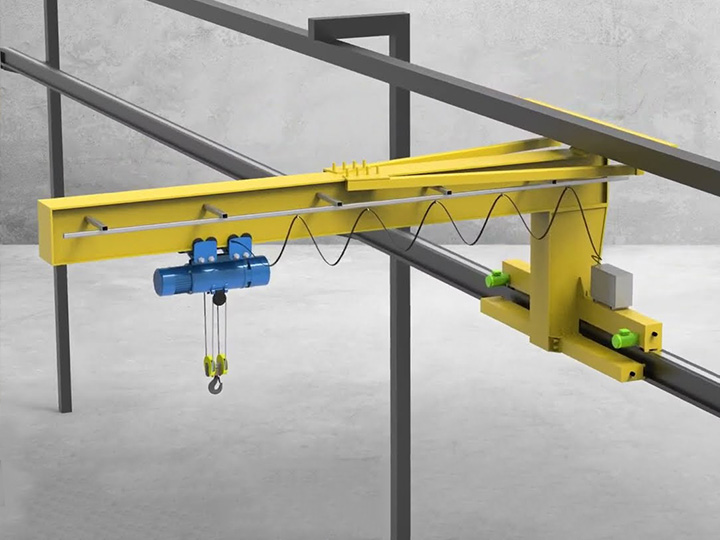

Wall traveling jib cranes build upon the structure of traditional column-mounted jib cranes. These cranes run along walls or other supporting structures on elevated tracks, providing efficient material handling in these specific areas. Unlike ground-mounted models, they require no floor space or concrete foundations, making them particularly suitable for workshops, assembly lines, and warehouses where ground clearance is limited.

Articulating jib cranes are small, portable lifting devices with a unique arc-shaped boom structure that allows for easy extension, retraction, and rotation. They are simple and flexible to operate and have a wide operating range. The core structure consists of a horizontally rotatable mast or support, with the base cantilever supporting 270° rotation and the arc-shaped boom section rotating 180°, meeting multi-angle and multi-directional lifting needs. They are particularly suitable for space-constrained locations, providing an efficient solution for lifting operations in confined spaces.

When choosing a jib crane, the following key factors need to be considered:

First, clearly define the specific operational requirements, including the maximum weight, size, and shape of goods to be typically lifted, as well as the daily operating frequency and required speed.

The "boom span" (i.e., the effective working radius of the cantilever) directly determines the crane's coverage area. You need to accurately calculate the required boom span based on the size and layout of the work area to ensure the hook can unobstructedly cover all critical work points.

The rated load capacity of the jib crane must be greater than the maximum weight you need to lift, and it is recommended to leave a certain safety margin. Any overloading must be strictly avoided to prevent equipment failure and ensure safety.

The spatial conditions of your installation site determine the suitable crane type. Therefore, you should measure the area's height, width, and depth and confirm the absence of any overhead or nearby obstacles, guaranteeing your final selection integrates perfectly into the available space.

To ensure the safe and reliable operation of jib cranes and extend their service life, the following maintenance measures are crucial:

When selecting a jib crane type, a thorough understanding of the performance and applicable scenarios for each model is crucial. Fixed-column jib cranes are suitable for high-frequency operations in fixed locations; mobile jib cranes are flexible and can meet the needs of multi-station handling; wall-mounted compact designs are suitable for space-constrained environments; and folding cantilever cranes offer high adaptability and can handle a variety of complex lifting tasks.

Weihua Cranes' professional team provides detailed quotations and technical guidance to ensure you choose the jib crane solution best suited to your industrial needs. Contact us to make the perfect lifting choice.

Submit Request