Light Cranes

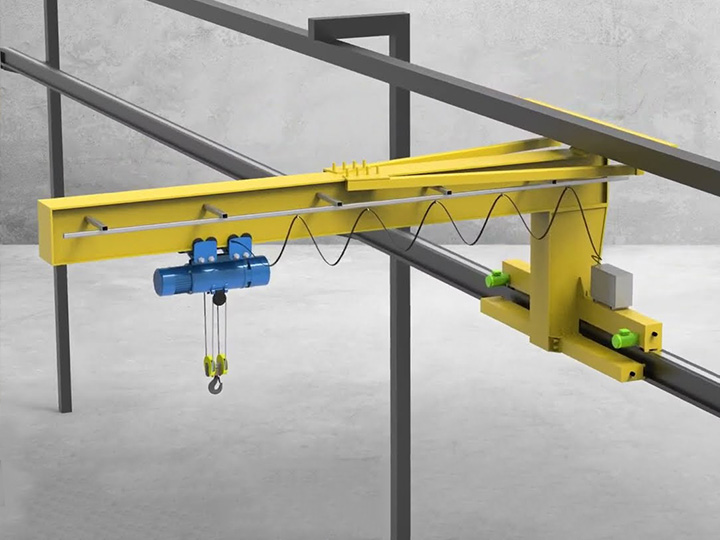

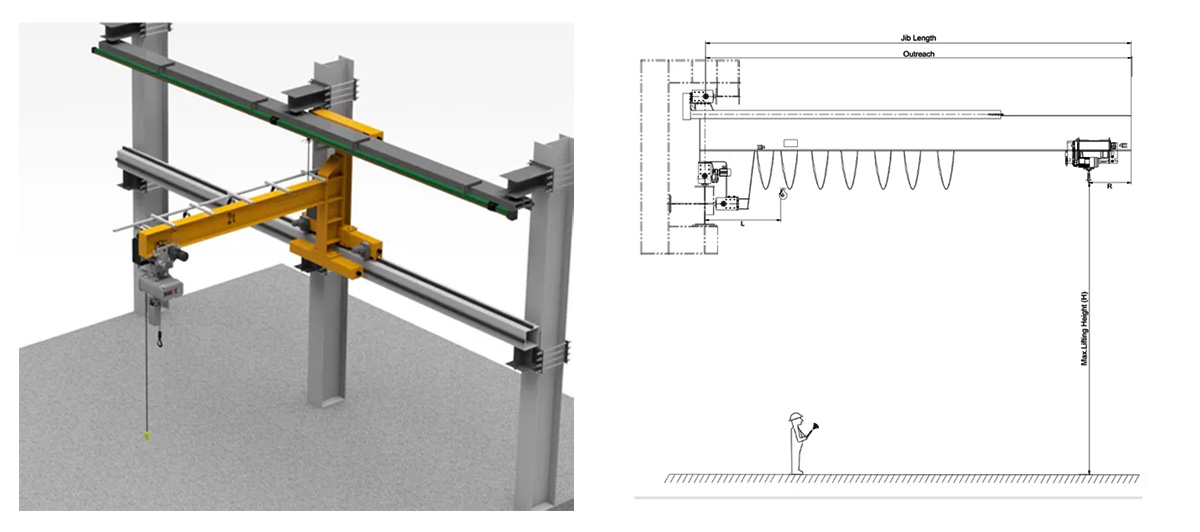

A wall traveling jib crane is a movable, small material handling device developed based on a wall bracket jib crane that often works with an electric hoist. Its running track is fixed on the concrete columns of the plant and can be moved longitudinally along the track, while the electric hoist can realize lateral movement and vertical lifting and lowering functions on the cantilever. The design of wall-traveling jib cranes significantly improves the operational coverage and optimizes the utilization of plant space, which is particularly suitable for use in factories, workshops, production lines, assembly lines, machine tool loading and unloading operations, as well as warehouses, wharves, and other places of heavy lifting tasks.

A wall traveling jib crane is a type of jib crane that can be moved on an elevated track on a wall or other support structure, offering a variety of load capacities, usually ranging from 0.5-5 tons, depending on the specific model. The main girder construction is divided into two forms: single girder and double girder, where the single girder includes both fixed and slewing jibs. The size of the running track can be customized according to user requirements. Please refer to this article for details: 5 Types Of Jib Cranes, How To Choose?

Wall-traveling jib cranes are suitable for short-distance, high-frequency, intensive lifting operations. It has the features of high efficiency, energy saving, space-saving, easy operation as well as easy maintenance, and is widely used in the scenarios of machinery manufacturing and assembly workshops. The application industries and scenarios of wall-traveling jib cranes include:

Wall traveling Jib Crane is mainly composed of the cantilever beam, slewing device, electric chain hoist, and other parts.

| Lifting Capacity | 0.5 ~5 ton |

| Lifting Height | 5~6 m |

| Lifting Speed | 8 M/Min |

| Traveling Speed | 20 M/Min |

| Max Length | 4.3~5.43 M |

| Total Weight | 389~420 KG |

| Slewing Angle | 180°,270°, 360° and customized |

The Wall Traveling Jib Crane is a highly efficient and flexible material handling equipment, especially suitable for use in workshops and warehouses where space is limited but a wide range of lifting operations are required. To ensure that this equipment is perfectly suited to your actual needs, please provide specific information according to the following tips:

Maximum lifting capacity: e.g., 0.5 tons, 2 tons, 5 tons, etc.

Boom Length: The extension distance of the boom determines the work coverage. Please provide the required effective span or slewing radius.

Mounting Height & Building Structure: At what height will the crane be installed? Does the wall or steel structure meet the load-bearing requirements?

Manual or Electric Traveling: Manual operation or electric drive? Is frequency control or intelligent positioning required?

Swing Angle: Is full swing (360°) or partial swing (e.g., 180°, 270°) required?

Working Environment: Does the workplace have special requirements, such as high temperatures, corrosive environments, or explosion-proof conditions? Does it need a dustproof and waterproof design?

Power Supply: Please provide the voltage, frequency, and power supply mode (e.g, 380V/50Hz three-phase power).

Control System: Do you need remote control, button box control? Does it integrate PLC or link with other equipment?

Whether there are other Optional Features, such as safety protection devices, limit switches, weighing system, fault diagnosis module, etc..

Application Industry: What specific processes are they used for? For example: automobile manufacturing, ship repair, warehousing and logistics, metal processing, and so on.

Tell us your specific needs, and Weihua will provide you with customized wall traveling jib crane solutions.

Weihua is a leading Wall Traveling Jib Crane manufacturer. We have over 30 years of crane manufacturing experience, and are equipped with advanced production equipment, a professional engineering team, and strict quality control processes. We can offer advanced material handling solutions tailored to your workspace layout and lifting needs. Our wall traveling jib cranes are designed to move along a fixed rail system, providing extended linear coverage along walls or building columns—ideal for assembly lines, production bays, and narrow work areas.

Contact us today for a free consultation and quotation. Let us design the right wall traveling jib crane for your operation.

Please feel free to leave a message. We will reply in 24 hours.

Submit Request