Дээд кранууд

50-ton overhead cranes perform heavy lifting tasks in demanding industrial environments. They utilize a double-girder construction to achieve both high load capacity and precise control. These cranes provide stable and flexible operation, making them perfectly suited for handling coils, supporting manufacturing and assembly lines, and meeting the demands of construction, logistics, and heavy industry sectors.

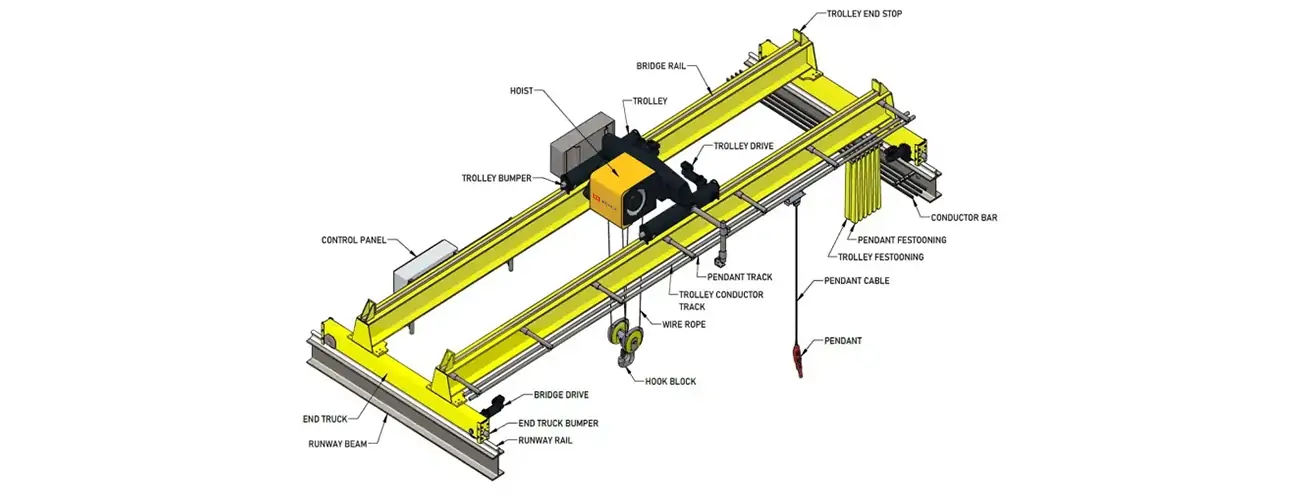

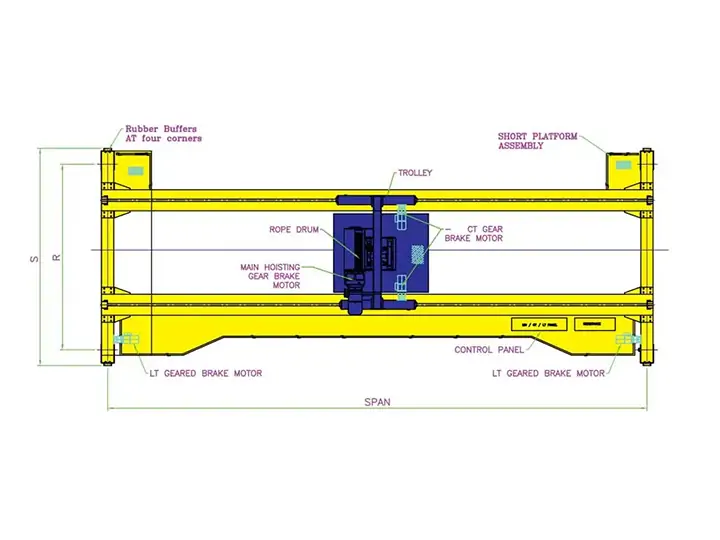

An overhead crane consists of a main girder, end beams, trolley running mechanism, bridge running mechanism, hoisting mechanism, tracks, driver's cab, and traveling platform. The functions and features of each component are as follows:

The QD double-girder hook crane is a heavy-duty industrial crane featuring a double-girder structure and a hook as a lifting device, enabling precise lifting and horizontal movement. It is widely used for lifting and handling materials in factories, warehouses, steel mills, hydropower stations, and other locations.

High lifting capacity: Suitable for handling heavy equipment and materials, meeting high-strength requirements.

Wide operating range: With a large span and height adjustment range, it can be flexibly moved over a wide area, adapting to various work scenarios.

Stable and reliable: The sturdy steel structure and advanced manufacturing process ensure long-term stable operation.

The European double-girder overhead crane employs advanced European design concepts and manufacturing standards. As a result, it achieves a compact structure, light weight, and delivers smooth operation with high energy efficiency. Precisely because of these advantages, it primarily serves in demanding production environments such as warehouses, manufacturing workshops, and precision assembly lines.

Compact design: The lifting mechanism utilizes a three-in-one motor, which occupies a small space, effectively extending the operating range and eliminating blind spots in transportation.

Lightweight design: High-strength steel is used to reduce weight, construction costs, and energy consumption.

Stable operation: Equipped with a variable frequency control system, it achieves millimeter-level positioning accuracy and zero-impact starting and stopping, meeting the needs of precision operations.

The electromagnetic overhead crane operates as a highly efficient material handling device. It works by utilizing a removable electromagnet to transport and lift metal materials. Therefore, you will commonly find this equipment serving key industries, for example, in steel mills, ports, and scrap yards, as well as other sites that require large-scale handling of ferromagnetic materials.

Current cut-off control eliminates the need for manual hooking and unhooking, improving safety and reducing labor intensity.

Magnetic field strength is adjusted by current control, providing convenience and efficiency.

Equipped with an energy storage device, it offers enhanced safety and easy maintenance.

The QDY Metallurgical Bridge Crane operates as a specially designed double-girder crane. Its core function is to safely lift molten metal in steel mills and metallurgical facilities. Therefore, it proves especially effective when handling hot steel and other high-temperature materials.

Excellent Heat Resistance: High-temperature resistant materials and heat dissipation devices ensure stable operation of critical components in extremely high-temperature environments.

High Safety and Reliability: Multiple safety features, including overload protection and an emergency stop button, ensure operator and equipment safety and minimize downtime.

The YZ type foundry crane is a heavy-duty lifting device designed specifically for steelmaking plants. It is primarily used for lifting, pouring, and mixing high-temperature liquid metal.

YZ Type Steel Foundry Crane

The crane's spreader supports 360-degree rotation, enhancing operational flexibility.

The steel mill crane is equipped with intelligent load limiting and real-time alarm systems to ensure safe operation.

Key components of the foundry crane are made of heat-resistant materials and feature protective measures.

The QY insulated overhead crane acts as a specialized lifting device. It is specifically engineered for non-ferrous metal electrolytic smelting plants. Therefore, it is primarily deployed in work environments that require reliable electrical insulation, such as those handling aluminum, magnesium, lead, and zinc.

Professional insulation protection: Effectively isolates current, with insulation resistance of at least 1MΩ at room temperature of 20°C-25°C and humidity ≤85%.

Multiple safety features: Equipped with dual brakes, overload protection, and an insulation fault alarm system, it comprehensively reduces operational risks.

Durable structural design: Corrosion-resistant coating and IP54 protection rating extend service life in harsh environments.

The QB explosion-proof overhead crane operates as a lifting device specifically engineered for hazardous locations with flammable and explosive atmospheres. Its design ensures that all main components utilize certified explosion-proof structures and materials. Precisely because of this inherent safety, it fulfills all rigorous national and industry explosion-proof requirements. Consequently, industries with critical safety needs—including petroleum, chemical, natural gas, military, and pharmaceuticals—rely on this equipment.

QB Explosion Proof Overhead Crane

Explosion-proof design: All key components (motor, lifting mechanism, and electrical components) are made of explosion-proof materials.

Highly adaptable: It can be equipped with magnets, hooks, C-type hooks, and other options to meet the needs of various working scenarios.

Safe and reliable structure: The main beam and end beams are welded from high-quality steel, and non-metallic components are made of anti-static materials.

The multi-functional roasting crane operates as a specialized lifting solution for high-temperature roasting in industries like metallurgy, chemicals, and building materials. Its core function is to handle multi-station operations within these facilities. For instance, it routinely executes critical tasks such as feeding, unloading, transferring, and storing materials in and around high-temperature furnaces.

High-temperature resistant structural design: Key components utilize water-cooled motors, insulation, and heat-resistant materials to withstand high-temperature roasting environments up to 800°C.

High-precision intelligent control: Integrated PLC system and variable frequency speed regulation technology enable automatic gripping, precise positioning, weight recognition, and fault self-diagnosis, improving production automation.

Overhead slab handling cranes, also called billet cranes, serve as heavy-duty equipment specifically designed for continuous casting and rolling lines in the steel industry. They are primarily used to handle slabs at various temperatures. Their tasks include transferring, stacking, loading, and unloading both high-temperature and room-temperature slabs.

High-temperature resistant design: Utilizing a thermal insulation coating and a water cooling system, it can withstand temperatures exceeding 650°C for extended periods.

Intelligent clamping system: Equipped with rigid, flexible, and rotating clamps, hydraulic, and electric clamping mechanisms, the system provides stable clamping, and some models feature automatic centering.

Вэйхуа групп is committed to providing customers with customized lifting solutions to meet their specific needs. We offer modular designs to meet diverse requirements while ensuring structural stability and standardized production.

Lifting capacity: Customizable

Span: Customizable

Lift height: Customizable

Control options: Pendant, remote control, or cabin control available.

Hoist type: Wire rope or chain hoist

Certifications: CE, ISO, EAC, etc.

If you have any specific needs or require further assistance, please contact our team of experts and share your work requirements. We will be happy to provide you with customized solutions and professional support.

The price of a 50-ton bridge crane depends on span, lifting height, duty class (A5-A7), control method, and custom features such as explosion-proof or weatherproof design. Weihua Group can provide layouts, specifications, and quotes within 12 hours.

Our 50-ton bridge cranes offer spans from 10.5m to 35m and lifting heights up to 30m, allowing for full customization based on site layout.

Yes. Our 50-ton cranes are weatherproof and suitable for outdoor operations in steel mills, power stations, and high-duty-cycle mining sites.

All Weihua 50-ton cranes are CE-certified and include overload protection, limit switches, two-speed hoisting, and an optional anti-sway system for enhanced safety.

According to ISO crane maintenance standards, routine inspections are recommended every 250 hours, and major preventive maintenance is recommended every 2,000 hours.

Yes, an optional real-time load monitoring system with overload alarm and data logging capabilities is available to enhance operational safety.

Та бүхэн мессеж үлдээгээрэй. Бид 24 цагийн дотор хариулах болно.

Хүсэлт илгээх