Аж үйлдвэрийн мэдээ

Electric hoists are essential tools for lifting and transporting heavy objects, designed to precisely and easily lift, lower, and move them. Choosing the best type of electric hoist can not only improve work efficiency but also ensure operational safety. This guide will help you understand the key factors to consider when selecting an electric hoist, helping you choose the best one for your specific needs.

Electric hoists are the core components of crane systems. A mismatched power rating or mismatched model can have a ripple effect on your operation, leading to equipment failure, safety incidents, or unnecessary maintenance costs. An optimal electric hoist can improve productivity, reduce operational risks, and extend equipment life. Selecting the optimal electric hoist for the environment and load is key to reliable, cost-effective material handling.

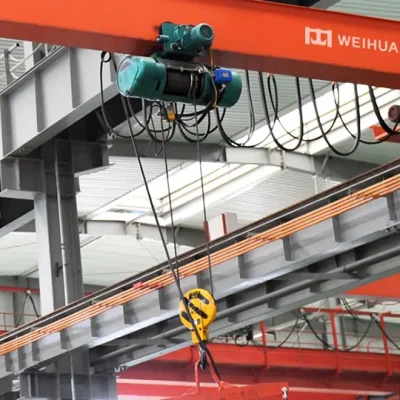

Electric hoists lift and lower heavy loads efficiently in industrial settings. They operate smoothly with minimal maintenance and integrate easily with bridge or gantry cranes, or function independently in workshops, warehouses, and job sites. Weihua Crane Group provides diverse models—such as wire rope, chain, and European-style hoists—and customizes them to fit your specific environment and needs.

The main components of an electric hoist include the motor, gearbox, drum or sprocket, wire rope or load chain, hook assembly, brake system, control system, and limit switches.

Wire rope electric hoists handle heavy-duty lifting tasks and serve industries like manufacturing, mining, and construction that demand large capacities and high lifting heights.They use high-strength steel wire rope wound on a drum to lift or lower materials, offering superior durability and load capacity.

wire rope electric hoist

Electric chain hoists are compact and maneuverable, making them particularly suitable for temporary operations such as equipment maintenance and assembly in confined spaces or under light loads. However, their lifting speed is relatively slow, making them unsuitable for high-frequency or heavy-duty lifting needs.

European-style electric hoists incorporate advanced European technology and a modular design, which integrates a high-efficiency brake motor, a precision reducer, and a frequency conversion speed control system, along with multiple safety protection devices. They are compact, lightweight, and operate smoothly, making them widely used in industries such as automotive manufacturing, machining, and warehousing logistics.

Explosion-proof electric hoists are lifting equipment specifically designed for flammable, explosive, and high-dust environments. Through special designs using explosion-proof motors, electrical components, and anti-static materials, they eliminate electrical sparks, friction sparks, and overheating, ensuring safe operation in hazardous locations such as petroleum, chemical, and coal mines.

When choosing an electric hoist for your lifting project, six important factors need to be considered: load capacity, operating environment, duty cycle, headroom, power supply, and control type.

1. Load Capacity

The load capacity of the electric hoist should be equal to or greater than the maximum weight you need to lift. Overloading the hoist can lead to equipment failure, safety risks, and increased maintenance costs.

2. Headroom

Headroom refers to the vertical available space between the hoist and the overhead structure or beam. If the work area has low ceilings or limited space, choosing a hoist specifically designed for low headroom applications is crucial.

3. Operating Environment

Select standard electric hoists or chain hoists for normal environments like dry, clean workshops; choose rust-proof and corrosion-resistant models for humid or corrosive conditions; use specially designed explosion-proof hoists in flammable and explosive areas; and opt for high-temperature resistant hoists to prevent overheating damage in high-temperature settings.

4. Duty Cycle

Duty cycle refers to the percentage of time the electric hoist operates within a complete work cycle. When selecting a model, a comprehensive evaluation of load weight and start/stop frequency is necessary. For continuous or high-frequency use, a model with a higher rated load and greater capacity should be selected to prevent overheating and ensure long-term stable operation.

5. Power Supply

Most electric hoists typically operate on three-phase power, but occasionally single-phase power is used. Ensure compatibility with your site's electrical infrastructure. Voltage mismatch can cause motor overheating.

6. Control Type

Pendant Control: Provides simple, user-friendly operation via a wired control unit.

Wireless Remote Control: Offers flexibility, allowing operators to manage the crane from a safe distance.

Choosing the best electric hoist hinges on whether it matches your workflow. By understanding the different types of electric hoists and evaluating key factors, you can select one that enhances safety, improves efficiency, and delivers long-term value. If you require expert advice or a customized quote, please contact our professional team today to find the perfect solution for your business.

A wire rope electric hoist is a lifting device driven by an electric motor that uses a wire rope wound on a drum to lift and lower heavy objects. It is widely used in industries such as construction, manufacturing, and warehousing due to its durability, accuracy, and high load capacity.

Electric wire rope hoists are available in various load capacities, from 500 kg to over 10 tons, and customization is supported.

Electric hoists serve industries like construction, manufacturing, warehousing, mining, oil and gas, and entertainment. They handle tasks such as lifting building materials and equipment, loading and unloading goods, moving heavy machinery, performing lifts in explosion-proof environments, and providing compact lifting solutions for stages.

Wire rope hoists: Designed for larger loads, higher lifting heights, and smoother operation. Suitable for heavy industrial applications.

Chain hoists: More compact structure, lighter load, suitable for shorter lifting heights. Typically used for small operations or confined spaces.

Overload protection: Prevents the crane from exceeding its rated lifting capacity.

Limit switches: Stop the crane at the maximum and minimum lifting heights.

Emergency stop: Allows the operator to immediately stop operation in an emergency.

Braking system: Ensures safe holding of the load during lifting and lowering.

Yes, many electric hoists are designed for outdoor use. Special materials are designed to withstand harsh environments such as rain, dust, and extreme temperatures. Ensure the hoist uses corrosion-resistant components to ensure its durability.

With proper maintenance, a wire rope electric hoist can last 10 to 20 years or even longer. The actual service life depends on factors such as usage frequency, load capacity, and environmental conditions.

Yes, modern electric hoists are equipped with energy-efficient motors that minimize power consumption while maintaining optimal performance. Variable speed motors further improve energy efficiency by consuming only the necessary power per run.

Yes, many manufacturers offer customization options, including lifting height, load capacity, and special material designs, to meet your specific needs.

Огноо:

Огноо:

Огноо:

Хүсэлт илгээх