Аж үйлдвэрийн мэдээ

Electric hoists are essential tools in industries such as construction, manufacturing, and warehousing. Typically, they utilize a drum wound around a rope or chain to lift or lower loads. As a result, they enable precise lifting, lowering, and moving of heavy objects, which saves time and reduces physical labor. Meanwhile, Weihua Crane Group, a leading electric hoist manufacturer in China, aims to provide high-quality, reliable, and affordable electric hoists to the global market.Therefore, this article provides a detailed introduction to the working principles, components, types, and applications of electric hoists, ultimately helping you make an informed choice based on your lifting needs.

An electric hoist is a type of industrial material handling equipment that, as the name implies, uses electricity to lift and lower large, heavy objects. Specifically, it consists of key components such as a motor, wire rope or chain, pulley, hook, and cable drum. Given this design, electric hoists are used for assembling heavy machinery, moving production line components, and performing equipment maintenance.As a result, they have become essential equipment for a wide range of infrastructure projects, including construction, highways, metallurgy, and mining.

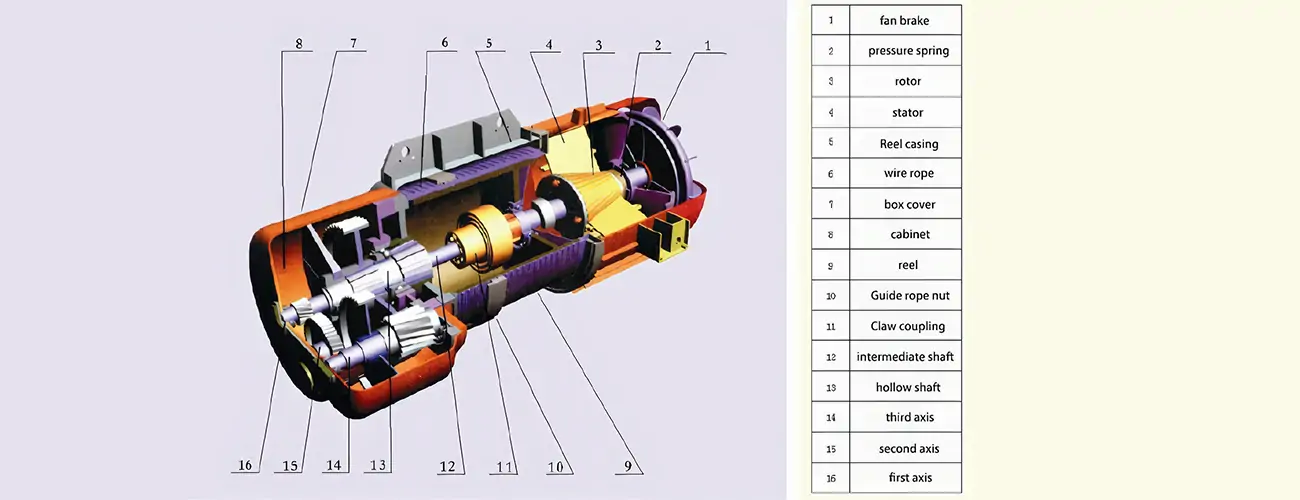

To understand how an electric hoist works, let's first look at its core components:

Motor: The electric motor provides the power needed to lift and lower the load. Once activated, it rotates the drum or gear system.

Gearbox: Converts the motor's high-speed, low-torque output into low-speed, high-torque power.

Rope or chain: Transmits the lifting force from the motor to the load, carrying the load's weight.

Braking system: Ensures safe load control and prevents slippage.

Hook: Attached to the end of the chain or wire rope, it connects the load to the electric hoist.

Control system: Allows operation via a switch or remote control.

Safety devices: Limit switches, overload protection, and emergency stop buttons.

Electric chain hoists use durable alloy chains to carry heavy loads. Compact and lightweight, they have load ratings ranging from 0.25 to 5 tons and are suitable for light-duty work.

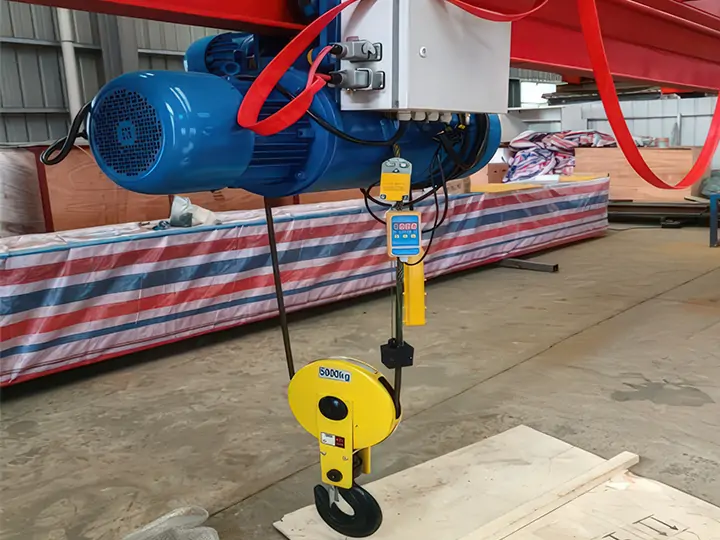

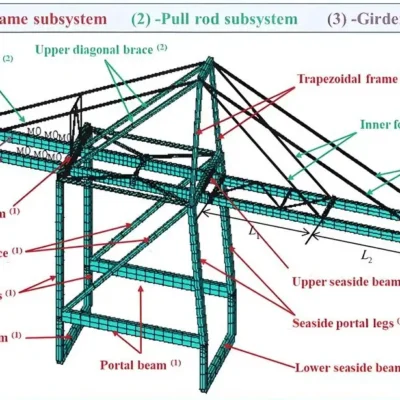

Wire rope hoist uses wire rope to achieve higher lifting height, usually installed on I-beam track, overhead crane or gantry crane, used to lift various heavy objects.

Explosion-proof electric hoist

Designed for safe and efficient lifting operations in hazardous environments. With a lifting capacity range of 1 to 32 tons and a lifting height of 6 to 48 meters, they are suitable for a variety of hazardous locations.

A special lifting equipment designed for lifting molten metal and other high-temperature solid objects. It is suitable for places without fire, explosion hazards and corrosive media, such as foundries, furnace workshops, smelters, power stations and other high-temperature occasions.

Choosing the right electric hoist is crucial to ensuring safe, efficient, and long-lasting lifting operations. Key considerations include:

By understanding the working principles, types, and applications of electric hoists, we can help you select the right one to improve your company's productivity and ensure workplace safety.

At Weihua Crane Group, we prioritize product safety, efficiency, and reliability. We not only provide high-quality products but also exceptional customer service. If needed, Weihua's professional team is always ready to assist you with product selection, installation, and maintenance, ensuring smooth equipment operation.

Q: How much weight can an electric hoist lift?

A: Capacity ranges from 0.25 tons to over 50 tons, depending on the model.

Q: Can electric hoists operate in explosive environments?

A: Yes. Explosion-proof electric hoists can be used in the oil, gas, or chemical industries.

Q: What maintenance does an electric hoist require?

A: Regular lubrication, brake inspection, and inspection of the wire rope/chain.

Q: How do limit switches and overload protection enhance the safety of an electric hoist?

A: Limit switches automatically stop hoist movement if travel limits or capacity are exceeded, while overload protection prevents operation beyond rated limits, protecting both equipment and operators.

Огноо:

Огноо:

Огноо:

Хүсэлт илгээх