Notizie

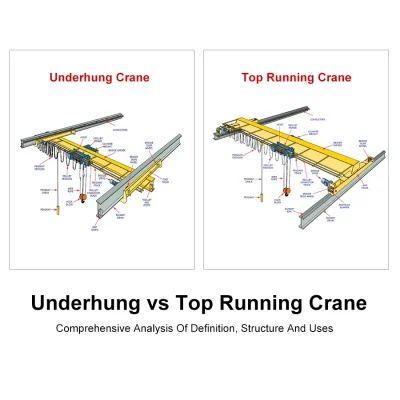

An underhung crane, also known as an under-running crane, is a type of overhead crane where the bridge is suspended from the bottom flange of a runway beam. Unlike top-running cranes, underhung systems are typically supported by the ceiling structure or a suspension framework, making them ideal for facilities with limited floor space or lower headroom. Commonly used in workshops, warehouses, assembly lines, and light manufacturing environments.

In this article, we'll walk you through the main types of underhung cranes, their beam design, core components, and typical trolley systems. We’ll also compare underhung cranes with top-running overhead cranes to help you make the best choice for your project. Continue reading to gain a comprehensive understanding of how underhung crane systems can meet the needs of your facility.

Underhung cranes come in various configurations to suit different applications and load capacities. Here are two commonly used types:

Lifting Capacity: Typically 1 to 10 tons

Application: Light to medium-duty lifting tasks in workshops and small factories

Features: Compact design, cost-effective, flexible runway configurations, easy installation, used for short spans and areas with limited headroom.

Lifting Capacity: Up to 20 tons or more, depending on design

Application: Medium to heavy-duty applications requiring higher hook height and longer spans

Features: Greater lifting height than single girder, can support more complex lifting equipment, used for manufacturing plants, maintenance areas, and material processing facilities.

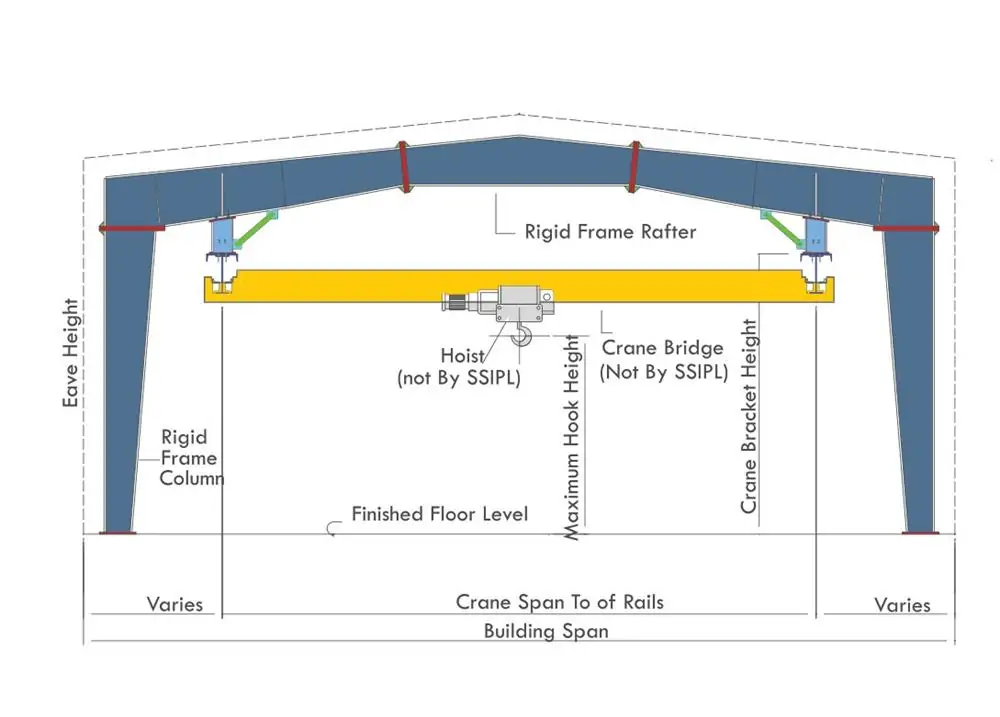

The beam design is a critical part of the underhung crane system. Depending on building structure and operational needs, the runway beams can be:

Ceiling-mounted (suspended runway): Requires robust structural support.

Freestanding structure (floor-mounted columns): Ideal for buildings without adequate roof support.

Design Considerations: Beam span, deflection limits, flange width, and structural integrity.

For unique layouts or load requirements, customized beam design options are available, including integration with curved tracks or interlocks for multiple bridge cranes.

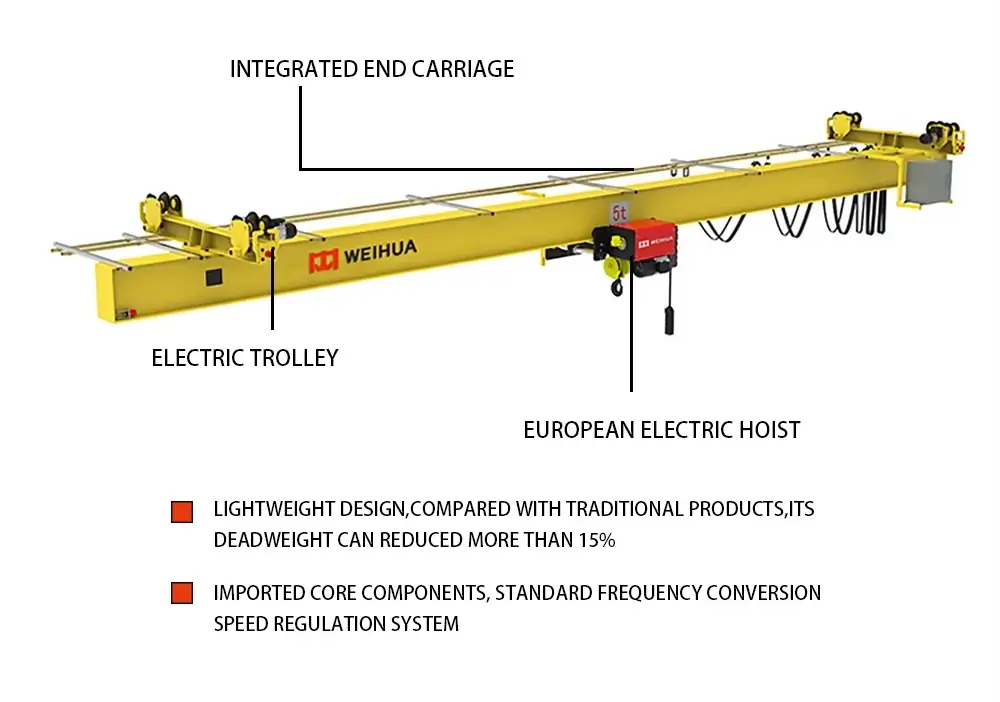

An underhung crane system commonly includes the following main components:

Bridge Girders: Carries the hoist and trolley; can be single or double girder

End Trucks: Support the bridge and move along the runway

Runway Beams: Mounted from the ceiling or supported by a frame, these beams guide the bridge

Electric Hoist: Performs the lifting and lowering of the load

Control System: May be push-button pendant, wireless remote, or integrated automation

Power Supply System: Commonly uses festoon systems or conductor bars

The trolley is the mobile unit that carries the hoist across the bridge girder. Key features include:

Underhung cranes are widely used in small-scale industrial settings and are ideal when flexibility, compact design, and easy operation are essential. Some typical applications include:

Choosing between underhung and top-running cranes depends on several factors such as building structure, lifting needs, and space availability.

| Feature | Underhung Crane | Top-Running Overhead Crane |

|---|---|---|

| Support Method | Requires a strong roof structure | Mounted on top of runway beams |

| Capacità di sollevamento | Up to 20 tons (typical) | Can exceed 100 tons |

| Building Requirements | Needs a floor-supported runway | Offers a higher hook height |

| Installation | More flexible, ideal for tight areas | Requires more space |

| Hook Height | Limited by beam clearance | Offers higher hook height |

| Cost | Generally more economical | Suspended from the ceiling/runway |

Recommendation:

If your facility has space or structural limitations, an underhung crane is often the better solution. For heavy-duty lifting and long spans, top-running cranes are more suitable.

When considering a suspension crane system, we recommend that you first thoroughly evaluate your specific needs, such as load weights and dimensions, required coverage area, work cycle intensity, and any special environmental factors (e.g., corrosive environments or extreme temperatures). Consult a structural engineer to confirm whether your building can withstand the concentrated loads at the rail connection points.

Weihua Group specializes in the design and manufacture of customized suspension crane systems. Our engineering team is ready to assist you with load calculations, structural analysis, and system configuration to ensure you get the most cost-effective solution.

Data:

Invia la richiesta