Notizie

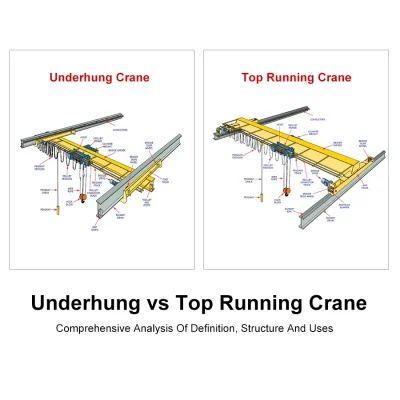

Bridge cranes are an essential piece of equipment for material handling in manufacturing, construction, and warehousing industries. Top-running cranes and Underhung cranes are two common types of cranes. The Top-Running Crane and the Underhung Crane are two common types of bridge cranes. Although they are both used for lifting and moving heavy loads, their structural design, load capacity, and applications vary significantly. This article will cover the definitions and differences between underhung vs top running cranes, and how to choose the right crane for your needs. Please read on.

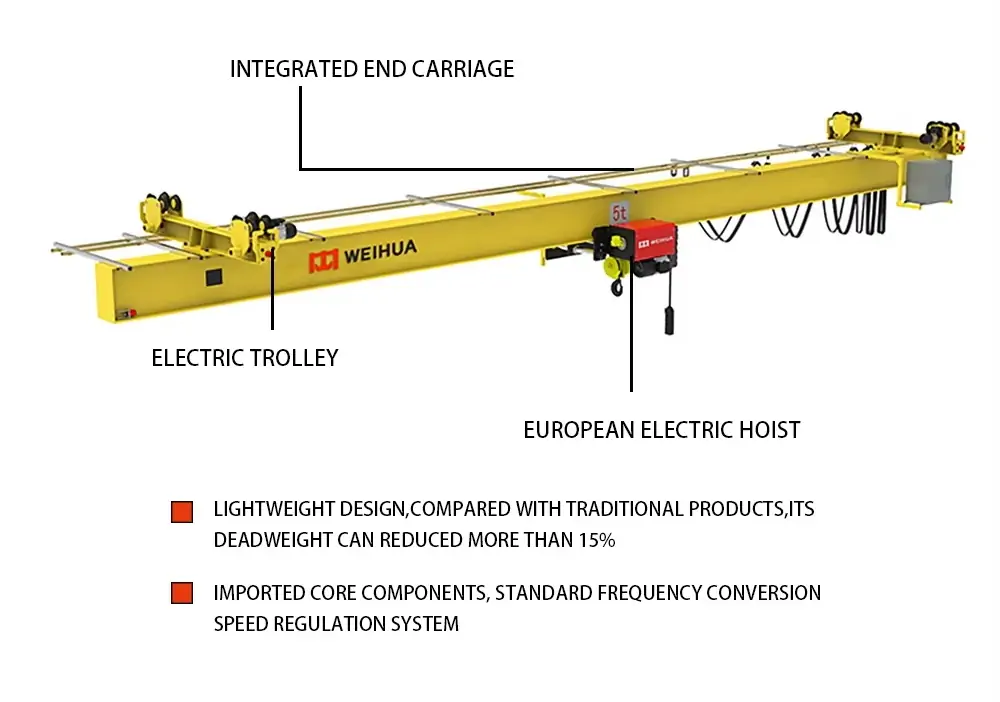

Underhung Crane operates differently from Top Running Crane. Instead of running on the top of the railroad girder, the crane's trolley and bridge are suspended from the bottom flange of the overhead girder. The crane has a light lifting capacity (1 to 20 tons) and is typically used in facilities with limited headroom or where maximum use of floor space is required. Widely used in assembly lines, machine shops, and small manufacturing cell scenarios. Check out this article for details: What Is an Underhung Crane? Detailed Guide

A Top Running Crane is a type of overhead crane in which the bridge moves on rails mounted on top of track girders, usually supported by building structures or freestanding columns. With a wide range of load capacities, typically from 1 to 800 tons, its design allows for maximum hook height and efficient use of vertical space. They are widely used in factories, large warehouses, steel mills, automotive plants, and other industries.

Top-running cranes require a sturdy support structure (columns or building frame) to carry heavy loads.

Underhung Cranes attach directly to the ceiling or roof structure and are better suited for facilities with space constraints.

The Top Running Crane can carry heavier loads (up to 800 tons).

The Underhung Crane is designed for light loads (typically less than 20 tons).

The higher hook height of the Top Running Crane allows for efficient use of vertical lifting space. It is suitable for buildings with limited headroom.

The Underhung Crane may have a restricted lifting height due to the suspension system and is suitable for buildings with low headroom.

Top Running Crane: Higher Initial Cost but Long-term Durability

Top Running Crane is mostly used in heavy industrial environments and requires strong track beams, reinforced support structures, and high-capacity hoisting mechanisms. As a result, the initial investment cost is higher than for suspension cranes. The installation process is also more complex, often requiring structural reinforcement of the building or additional independent pillars to support the crane system.

Underhung Crane: Cost-effective and easier to install

Underhung Cranes are mostly used in light industrial environments, where they are lighter in construction and have simpler support requirements, and therefore lower budgets than top-running cranes. Underhung Cranes are usually suspended from existing ceilings or roof structures, and therefore do not require additional runway beams or floor supports. Additional runway beams or floor supports are not required. It is ideal for retrofitting existing facilities without major structural changes, and is faster and less disruptive to install.

When choosing between Underhung vs Top Running Crane, some factors need to be evaluated to ensure that the equipment matches your operational requirements and site conditions:

If the application involves high-frequency heavy lifting, such as steel fabrication, casting, or heavy assembly, the Top Running Crane has more load-bearing advantages and is suitable for larger tonnages of material handling. For light to medium loads or light-duty work such as assembly lines and warehousing, the Underhung Crane provides adequate support and flexibility, making it more cost-effective.

Top Running Crane is usually mounted on top of the main beams of a factory building, which is suitable for workshops with high headroom and good structural load-bearing capacity; while Underhung Crane can be directly suspended from the roof or under the secondary beams, which is more suitable for large-span spaces with limited headroom or without load-bearing roof frames.

In small to medium-sized plants where budgets are limited or space is at a premium, the Underhung system is a more cost-effective choice due to its lightweight construction, ease of installation, and low maintenance costs. The Top Running system is a slightly higher investment, but it is better in terms of efficiency and durability, and is suitable for long-term heavy-duty operations.

Through the comparative analysis of Underhung vs Top Running Crane, we know that the selection of overhead cranes should take into account the equipment's load carrying capacity, available space, and plant structure support conditions, as well as the track layout, traveling frequency, electrical system configuration, later expansion needs and other factors. If you need to know more about which crane system is more suitable for your project, please contact Weihua's professional engineering team. We will provide accurate selection suggestions and customized solutions according to your site conditions and production requirements.

Data:

Invia la richiesta