Notizie sul settore

As one of China's leading crane suppliers, Weihua Crane Group offers a wide variety of electric hoists, including wire rope hoists, chain hoists, low-headroom hoists, European-style hoists, and explosion-proof hoists. This article explains the components, operating principles, and application scenarios of electric hoists. Contact us and we'll provide the optimal solution to meet your needs in the most cost-effective manner.

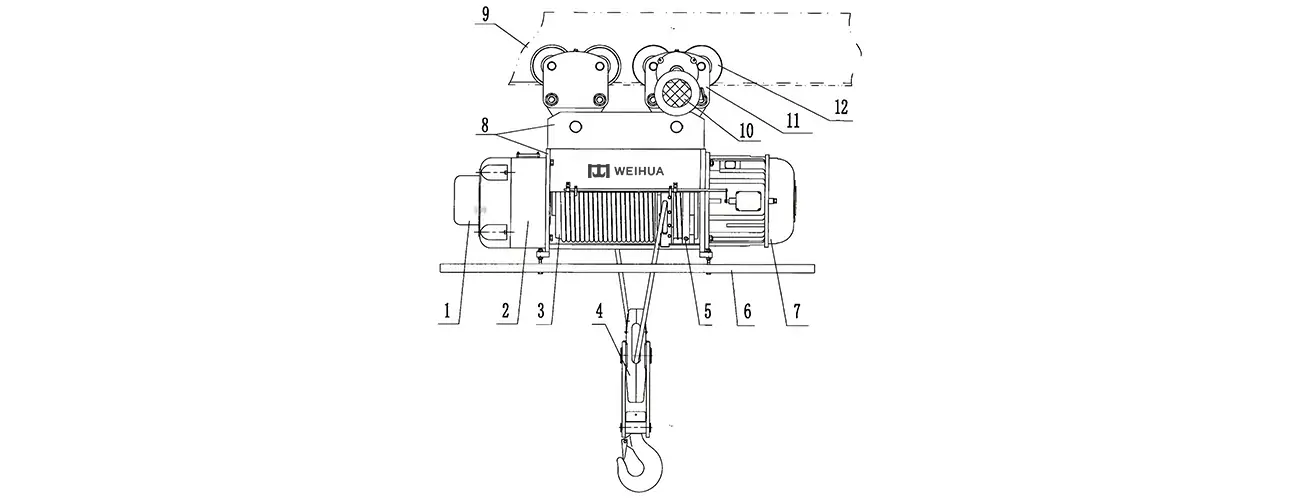

wire rope electric hoist

An paranco elettrico is a mechanical device powered by electricity and used to lift, lower, or move heavy objects with minimal human intervention. It typically consists of a motor, a gearbox, a drum or chain system, and a control panel. Designed for efficiency and precision, electric hoists are a vital component of all hoist systems, including overhead cranes and gantry cranes.

An electric hoist converts electrical energy into mechanical energy, rotating the motor and lifting the load via a chain or wire rope. This system ensures stable lifting and precise positioning.

Understanding the components of an electric hoist helps you understand its performance and reliability. The main components include:

Chain hoists are compact and well-suited for working in confined spaces or with light loads. They are maneuverable and easy to carry, making them ideal for temporary tasks such as maintenance and assembly. However, due to their slow lifting speed, they are not suitable for frequent or heavy lifting operations.

Applicazioni

1. Widely used for direct lifting of materials in various locations, such as factories, workshops, and warehouses.

2. Mounted on the straight or curved beam of a single-girder crane to lift cargo.

3. Can also be used with double-girder electric hoists, gantry cranes, and slewing cranes to lift a variety of items.

A wire rope electric hoist is a lightweight and compact lifting device that can be used not only as a standalone tool but also in conjunction with other equipment, such as overhead cranes, gantry cranes, and jib cranes. Consequently, it sees widespread use in numerous locations, including railways, docks, industrial and mining enterprises, and warehouses.Compared to chain hoists, wire rope hoists offer greater durability and load capacity, but they are generally more expensive and require a larger installation space.

Applicazioni

Power Industry: Electric wire rope hoists are used to assist in lifting equipment during the construction and maintenance of thermal power plants and hydropower plants.

Steel Industry: Used for lifting raw materials and finished products in steel mills.

Warehousing and Logistics: Used for loading and unloading, stacking, and lifting cargo in warehousing and logistics.

The design and manufacture of European electric hoists adhere to FEM and DIN standards. Incorporating 3D solid modeling and finite element analysis techniques, we further optimize the gear transmission, housing structure, and component dimensions, achieving optimal values for each component. This reduces their dimensions and saves installation space.

Applicazioni

Warehouse and Logistics: Suitable for high-bay rack handling and automated warehouses. Its low-headroom design maximizes space utilization and improves storage efficiency.

Food and Pharmaceutical: Utilizing stainless steel and food-grade lubrication, it meets the requirements of cleanrooms, such as filling lines and packaging equipment lifting.

Electronics and Precision Manufacturing: Suitable for handling semiconductor devices and LCD panels, equipped with an anti-sway feature.

Explosion-proof electric hoists are lifting equipment specifically designed for use in flammable, explosive, and dusty environments. Their design and manufacturing utilizes specialized processes, including explosion-proof motors, explosion-proof electrical components, and anti-static materials, effectively preventing explosions caused by sparks, friction sparks, overheating, and other factors.

Applicazioni

Coal Mining Environments: Approved for deployment in non-mining working areas of Class I explosion-proof coal mines.

Chemical Industry: Certified for operation in Class II explosion-proof locations that handle Class IIA, IIB, and IIC flammable gases or vapor-air mixtures.

Oil and Gas: Rated for use in areas handling flammable gases or liquids, with a coverage of temperature classes T1 through T4.

Metallurgical wire rope hoists are primarily used as metallurgical lifting equipment for lifting molten metal. They have a lifting capacity of less than 10 tons and a lifting height of less than 20 meters. They operate in an ambient temperature range of -10°C to 60°C, with an ambient temperature of 40°C and a relative humidity not exceeding 50%. They feature protective features such as dual brakes, dual limit stops, and thermal insulation panels.

Applicazioni

Foundries: Lifting and dumping ladles of molten steel and iron, as well as handling sand molds, castings, and other materials.

Furnace plants: Used for charging, transferring molten metal, and removing waste.

Smelters: Transporting raw materials such as ore and coke, and lifting finished products such as steel and aluminum ingots.

The following is a general price range based on the lifting capacity and type of electric hoist:

| Capacità di sollevamento | Price Range (USD) |

| 0.5-ton electric hoist | 200−500 |

| 1-ton electric hoist | 300−800 |

| 2-ton electric hoist | 500−1,200 |

| 3-ton electric hoist | 800−1,800 |

| 5-ton electric hoist | 1,500−3,000 |

| 10-ton electric hoist | 3,000−6,000 |

Singapore – 10-ton Wire Rope Electric Hoist for Mold Lifting

At an injection molding plant, Weihua's 10-ton wire rope electric hoist increased production speed by 30% and improved equipment maintenance and material loading efficiency.

Serbia – 5-ton European-style Electric Hoist for Steel Profile Handling

A steel plant installed a customized 5-ton European-style electric hoist for profile handling. The customer praised its stability and low noise levels during operation.

Chile – 5-ton MD1 Electric Hoist for Workshop Repair Stations

A Chilean customer uses a 5-ton MD1 electric hoist for engine lifting and part replacement. Its compact footprint and remote control system make it easy to integrate into existing workflows.

Compact and lightweight design – Easily fits into limited spaces

Precise operation – Variable speed, smooth start/stop

Energy-saving motor system – Reduces power consumption

Long service life – Durable and easy to maintain

CE certified, trusted worldwide – Exports to over 40 countries

By understanding the different types of electric hoists, evaluating key factors, and referencing real-world examples, you can choose one that enhances safety, improves efficiency, and delivers long-term value. If you're interested in electric hoists, please contact Weihua Crane Group. Our team of professional engineers is dedicated to providing you with high-quality, cost-effective service.

Data:

Invia la richiesta