Pièces détachées pour grues

The K Series Tripe Crane Gear Reducer is a highly integrated power transmission unit that combines a gearhead, motor, and brake (or inverter drive system) into a compact unit, usually with a helical-bevel gear structure. K series gear reducer, characterized by low energy consumption, reliability, and durability, high overload capacity, power up to 132KW, and reducer efficiency up to 95%.

The design saves installation space, reduces the number of external connecting parts, and improves transmission efficiency and reliability, making it suitable for compact, highly automated machinery and equipment, such as crane operators, conveyor systems, and mixing machines.

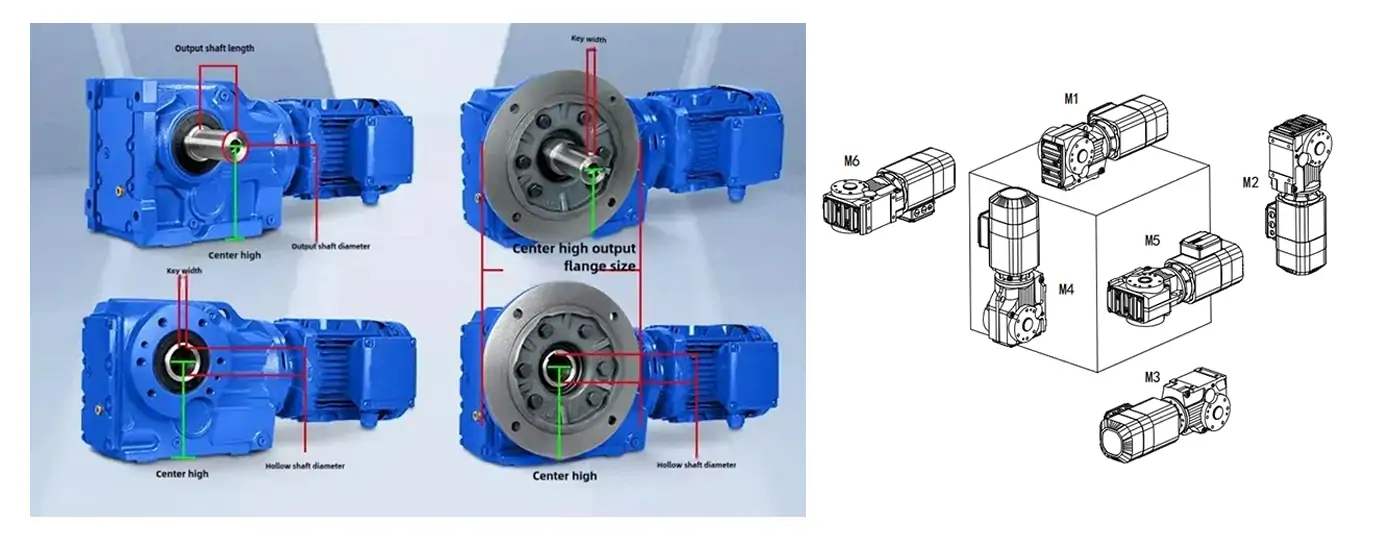

| Modèle | Output shaft diameter | Output flange size | Centerheight | Keywidth | Hollow shaft diameter | Hollow shaft diameter |

|---|---|---|---|---|---|---|

| Type37 | 25MM | 50 | 100 | 8 | 160 | 30MM |

| Type47 | 30MM | 60 | 112 | 8 | 200 | 35MM |

| Type57 | 35MM | 70 | 132 | 10 | 250 | 40MM |

| Type67 | 40MM | 80 | 140 | 12 | 250 | 40MM |

| Type77 | 50MM | 100 | 180 | 14 | 300 | 50MM |

| Type87 | 60MM | 120 | 212 | 18 | 350 | 60MM |

| Type97 | 70MM | 140 | 265 | 20 | 450 | 70MM |

| Type107 | 90MM | 170 | 315 | 25 | 450 | 90MM |

| Type127 | 110MM | 210 | 375 | 28 | 550 | 100MM |

| Type157 | 120MM | 210 | 450 | 32 | 660 | 120MM |

| Type167 | 160MM | 250 | 500 | 40 | 800 | 140MM |

| Type187 | 160MM | 320 | 600 | 45 | 800 | Output shaft diameter |

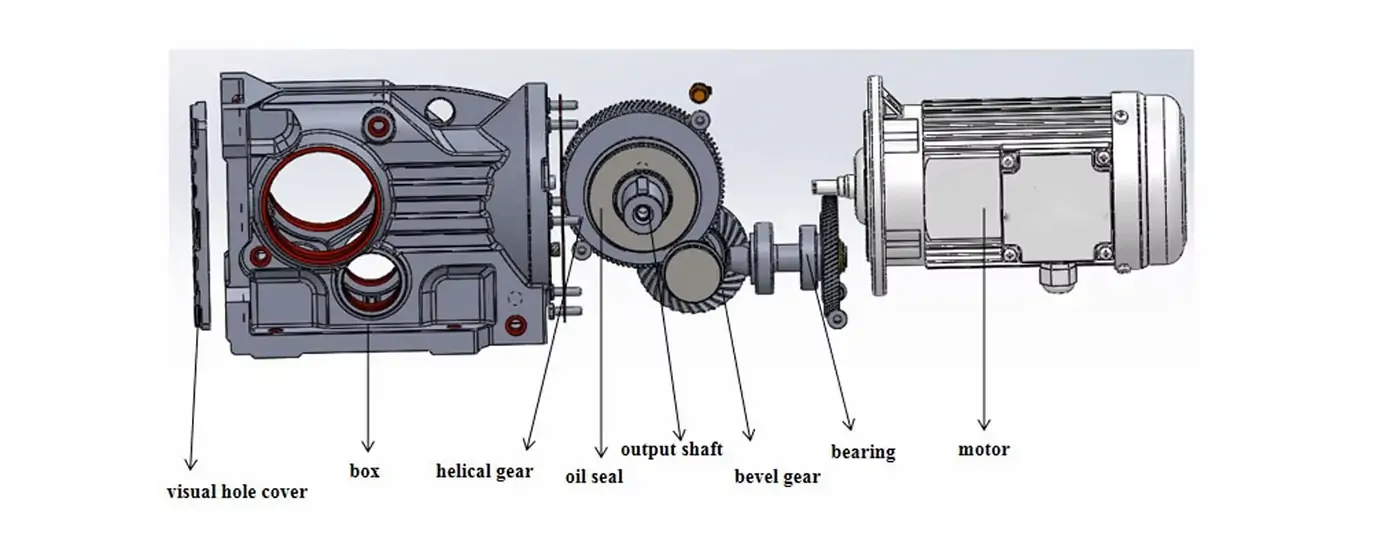

Housing: Made of high-strength cast iron for excellent rigidity and vibration damping.

Gears: Spiral bevel gears for smooth operation, low noise, and high torque.

Input configuration: Compatible with motors, solid shaft input, and IEC standard motor flanges for easy installation.

Applicable motors: Can be used with single-phase AC motors, three-phase AC motors, brake motors, inverter motors, multi-speed motors, explosion-proof motors, and drum motors.

Output configurations: Solid shaft output for direct connection. Hollow shaft outputs with keyway, shrink disk, or spline options for mounting flexibility.

With its integrated design, the K Series Triple Crane Gear Reducer is the ideal drive solution for modern industrial equipment, as it simplifies installation, saves space, and maintains high drive accuracy and reliability. Mainly used in the following equipment.

N'hésitez pas à nous laisser un message. Nous vous répondrons dans les 24 heures.

Soumettre une demande