Brückenkräne

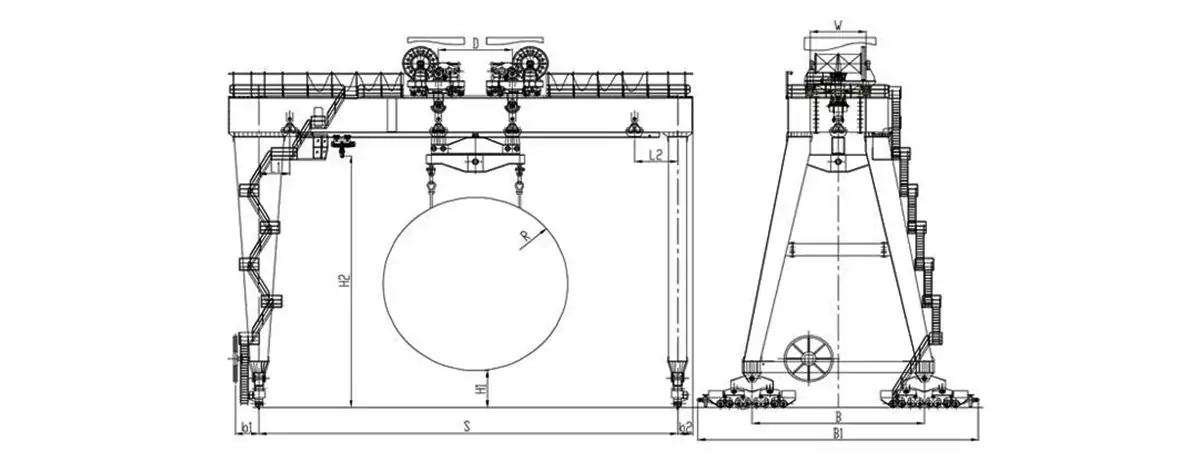

Heavy-duty gantry cranes are primarily used for lifting Tunnel Boring Machines (TBMs) and are large-scale lifting equipment specifically designed for debris removal, equipment transportation, and shield support operations in subway tunnel construction. They can automatically perform debris removal, unloading, and cycle operations to meet the material transportation requirements of tunnel construction. In addition to debris removal and unloading functions, this crane can also perform critical tasks such as tunnel pipe plate lifting and shield machine assembly, making it an indispensable piece of equipment in shield construction.

Heavy-duty gantry cranes are mainly divided into four series according to the lifting capacity and applicable tool diameter, which can meet diversified construction needs:

The upper spreader of the heavy duty gantry crane can be swung to adapt to the needs of excavation in different directions. For the special characteristics of shield construction, the spreader adopts a special design, equipped with adjustable clamps or hooks, adapting to different sizes and weights, and is able to firmly grasp irregularly shaped heavy parts such as the cutter plate, shield body, and pipe sheet.

The heavy duty gantry crane is mainly used for the following operations:

| Kapazität | T | 200+200 | |

| Spannweite | m | 33 | 34 |

| Hebehöhe | m | 48(obere Schiene 24l) (untere Schiene24l) | |

| Hebegeschwindigkeit | m/min | 0.09~0.9 ;7 | |

| Fahrgeschwindigkeit des Wagens | m/min | 1.15-11.5 | |

| Fahrgeschwindigkeit des Krans | m/min | 1.6-16 | |

| Max. Radlast | KN | 405 | 410 |

| Schiene empfohlen | Modell | QU100 | |

| Gesamtleistung des Motors | kw | 241 | |

| Hauptabmessungen (mm) | Spannweite(m) | 33 | 34 |

| Abstand der Kranbasis | W | 14000 | |

| Breite des Krans | B | 22800 | |

| Haken linke Begrenzung | S1 | 2500 | |

| Haken rechts Begrenzung | S2 | 3500 | |

| Kapazität | T | 100+100 | |

| Spannweite | m | 33 | 34 |

| Hebehöhe | m | 15+21 | |

| Hebegeschwindigkeit | m/min | 0.3-3-6 | |

| Fahrgeschwindigkeit des Wagens | m/min | 2.5-25 | |

| Fahrgeschwindigkeit des Krans | m/min | 2-20 | |

| Max. Radlast | KN | 270 | 290 |

| Schiene empfohlen | Modell | QU80 | |

| Gesamtleistung des Motors | kw | 225 | |

| Hauptabmessungen (mm) | Spannweite(m) | 33 | 34 |

| Abstand der Kranbasis | W | 12000 | |

| Breite des Krans | B | 19038 | |

| Haken linke Begrenzung | S1 | 2500 | |

| Haken rechts Begrenzung | S2 | 2500 | |

| Kapazität | T | 100 | ||

| Spannweite | m | 20 | 22 | 24 |

| Hebehöhe | m | 20 | ||

| Hebegeschwindigkeit | m/min | 0.37-3.7-6 | ||

| Fahrgeschwindigkeit des Wagens | m/min | 0.5-25 | ||

| Fahrgeschwindigkeit des Krans | m/min | 1.4-14 | ||

| Max. Radlast | KN | 230 | 235 | 240 |

| Schiene empfohlen | Modell | QU80 | ||

| Gesamtleistung des Motors | kw | 145 | ||

| Hauptabmessungen (mm) | Spannweite(m) | 20 | 22 | 24 |

| Abstand der Kranbasis | W | 10700 | ||

| Breite des Krans | B | 16380 | ||

| Haken linke Begrenzung | S1 | 1750 | ||

| Haken rechts Begrenzung | S2 | 1900 | ||

We are a leading manufacturer of heavy-duty gantry cranes, specializing in robust, high-capacity lifting solutions for industries such as tunnel boring, construction, shipping, mining, and logistics. We have advanced engineering capabilities and strict quality control, and deliver fully customized gantry cranes tailored to your operational demands, ensuring safety, efficiency, and long-term reliability. Contact us today for a free consultation. Let’s engineer the perfect gantry crane for your tunnel boring project!

Sie können uns gerne eine Nachricht hinterlassen. Wir werden innerhalb von 24 Stunden antworten.

Antrag einreichen