Brückenkräne

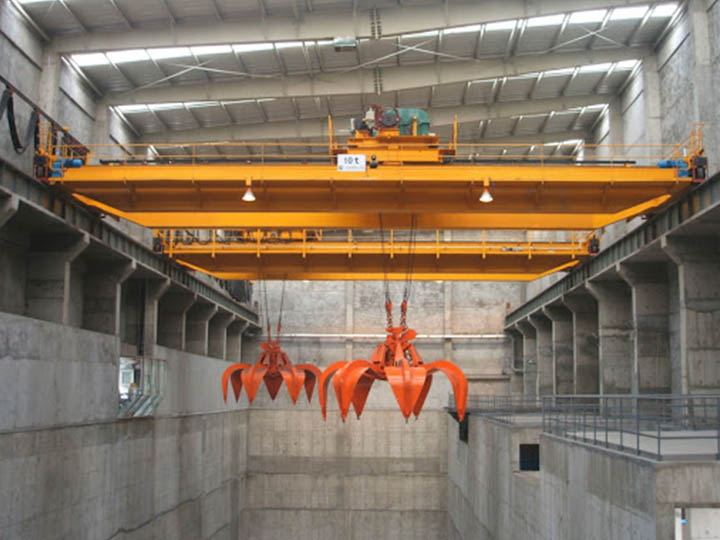

Grab Overhead Crane, also called "Waste Handling Crane," is a kind of heavy lifting equipment specially used in waste transfer stations, incineration plants, landfills, recycling centers, etc. It is mainly used for gripping, handling, stacking, and sorting all kinds of solid wastes, such as domestic wastes, industrial wastes, and construction wastes.

Waste Recycling Grab Crane

Waste Recycling Grab Crane

Coal Handling Grab Crane

Clamshell Grab Bucket for Bridge Crane

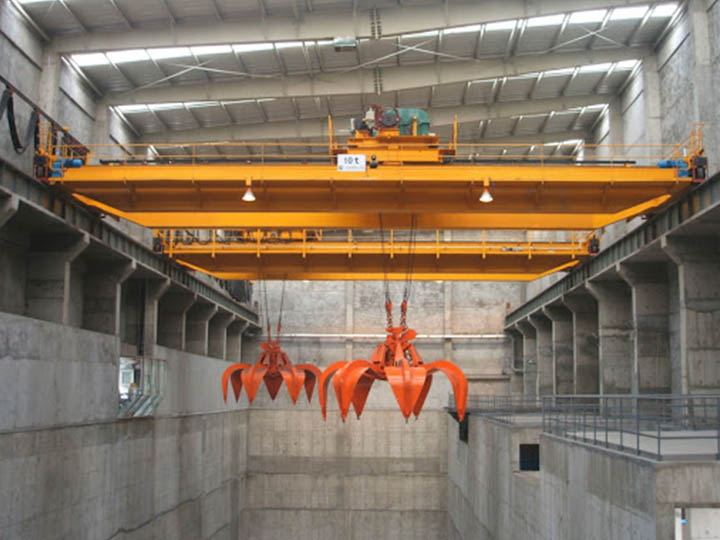

The Grab Overhead Crane is an overhead crane designed for bulk material handling. Its core function is to grab, lift, transport, and discharge materials by means of an electrically or mechanically driven Grab Bucket. Its working principle can be divided into the following key links:

A Grab Crane mainly consists of a bridge frame, an electric trolley, electrical equipment, and a grab etc. The bridge frame provides a stable support structure for the whole bridge crane. It carries the weight of each component and the load during lifting.

Bridge Girder: spanning the working area, the trolley runs horizontally along the track.

Lifting trolley: The trolley runs along the bridge and moves horizontally, equipped with a lifting mechanism and an opening and closing mechanism.

Grab Bucket: Usually double or multi-valve clamshell structure, opening and closing is controlled by wire rope or chain, suitable for bulk materials such as coal, ore, grain, etc.

Grabbing materials: The grab unfolds and descends to the material pile through the opening and closing mechanism, and relies on its own weight or hydraulic/electrical drive to clamp the materials when it is closed.

Lifting and Transportation: The lifting mechanism lifts the fully loaded grapple to the required height, and the large and small vehicles work together to transport the material horizontally to the target position.

Unloading: The grab opens again at the unloading point to release the material and complete the cycle.

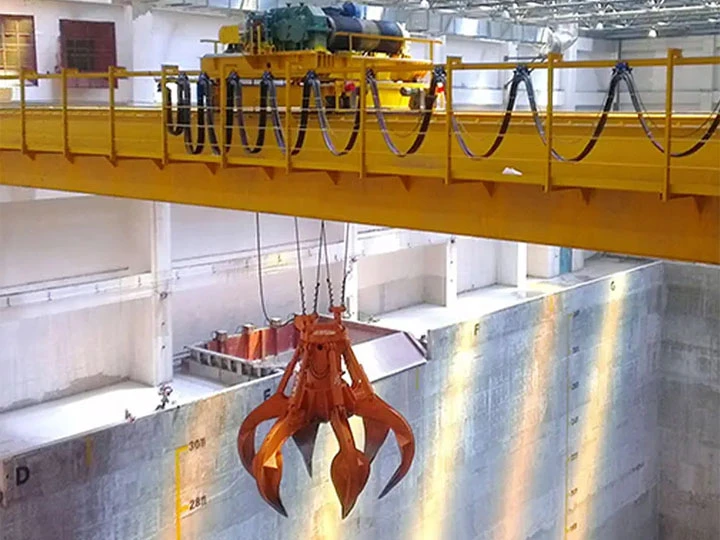

The waste handling cranes can choose different types of grabs according to the material characteristics, such as light grabs (grain), medium grabs (coal), heavy grabs (ore), and special grabs (garbage, scrap steel, etc.). Common grab buckets are of the following two types:

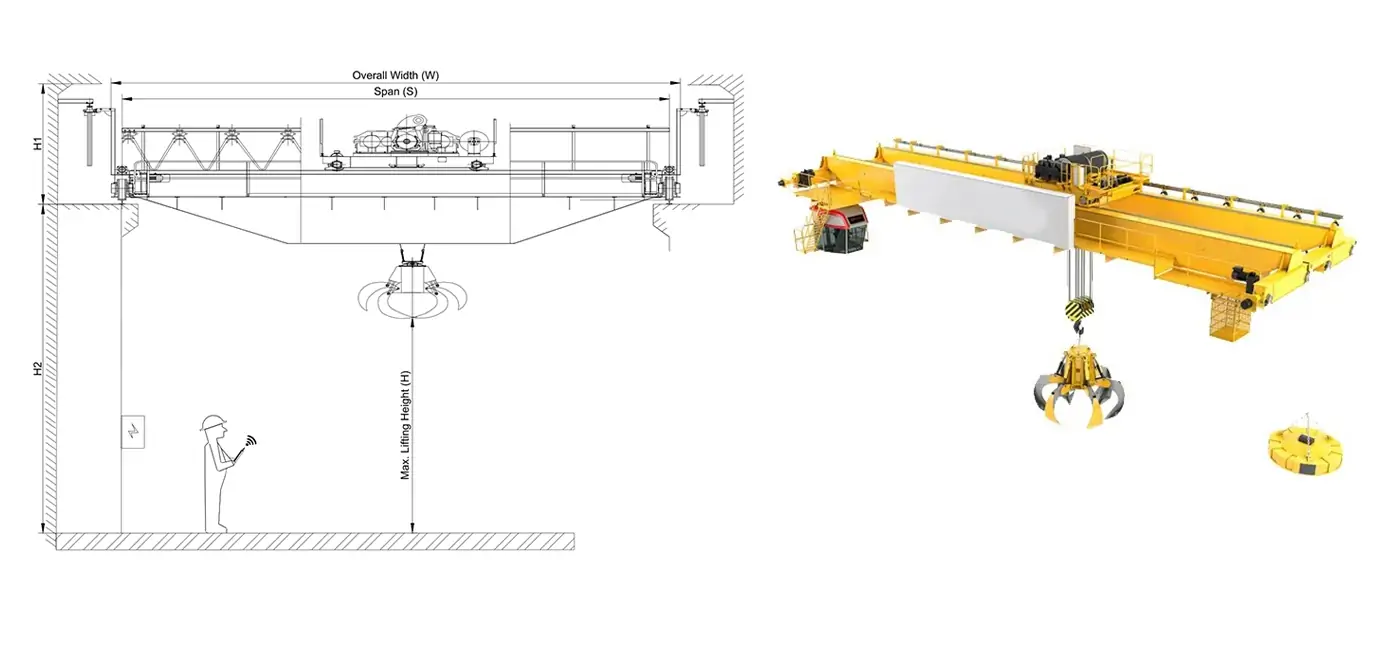

Multi-Flap Orange Peel Grab Bucket

Clamshell Grab Bucket for Bridge Crane

Structural features: composed of two symmetrical jaw flaps, similar to the “clamshell”, through the wire rope or hydraulic cylinder control, opening and closing.

Applicable materials: coal, ore, gravel, grain, and other bulk materials with good fluidity.

Advantages: simple structure, easy maintenance, and even gripping force.

Structural features: composed of 4~6 curved jaw flaps, similar to “orange peel”, forming a confined space when closed.

Applicable materials: steel scrap, garbage, irregular lump materials (such as metal scrap, construction waste).

Advantage: wide gripping range, adaptable to complex-shaped materials, and good leakage prevention.

The waste handling cranes are widely used in all kinds of bulk material handling industry, which has a highly efficient loading and unloading capacity, and is the key equipment in the fields of harbor, electric power, metallurgy, building materials, chemical industry, grain, and garbage disposal. Due to the different characteristics of materials handled in each industry, it is necessary to match the corresponding type of grab to ensure operational efficiency and safety.

Applicable materials: coal, iron ore, grain, fertilizer, sand and gravel, etc.

Application scenarios: loading and unloading of bulk carriers (coal, ore), transfer and stacking of yard materials, loading and unloading of containerized bulk cargoes (e.g., grains, fertilizers), etc.

Applicable materials: coal, ash, limestone.

Application Scenario: unloading, stacking, and loading of coal, cleaning and transferring of boiler ash, handling of limestone for desulfurization, etc.

Applicable materials: iron ore, coke, steel scrap, slag, copper ore.

Application Scenario: conveying of blast furnace raw materials (ore, coke), recycling and smelting of scrap steel, cleaning and transferring of slag and steel slag, etc.

Applicable materials: cement clinker, limestone, gypsum, sand, and gravel.

Application Scenario: raw material handling of cement production line, loading and unloading, and stacking of sand and gravel aggregate, storage management of gypsum and mineral powder, etc.

Applicable materials: fertilizer, salt, sulfur, plastic granules.

Application Scenario: Storage and transfer of chemical raw materials, material handling under an explosion-proof environment (such as aluminum powder, coal powder), loading and unloading of granular chemical products, etc.

Applicable materials: wheat, corn, soybeans, rice, sugar, fodder.

Application Scenario: loading and unloading and storage of grain in the granary, conveying of raw materials in the food processing plant, handling of granular materials in feed mill, etc.

Applicable materials: domestic garbage, construction garbage, industrial waste.

Application Scenario: feeding and transferring of garbage incineration plant, stacking and compaction of garbage in landfill, grabbing of scrap steel in scrap metal recycling station, etc.

| Tragfähigkeit(t) | 5 | 10 | 16 | 20 | |

| Spannweite(m) | 10.5-31.5 | 16.5-31.5 | |||

| Hubhöhe(m) | 20 | 18 | 28 | 26 | |

| Arbeiterklasse | A6 | ||||

| Geschwindigkeit (m/min) | Heben mit dem Hebezeug | 39.2 | 40.7 | 41.8 | 48.6 |

| Trolley fahren | 44.6 | 45.9 | 38.0 | 37.8 | |

| Kranfahren | 93.6/113.6 | 112.5/101 | 88/87.3 | 87.3 | |

| Stromversorgung | 380V, 50HZ, 3 Phasen oder andere | ||||

Whether you are handling bulk materials such as coal, grain, scrap metal or other loose commodities. Designed for efficiency, durability and precision, grab overhead cranes can be fully customized to meet the specific needs of your industry. Configurable as single or double girder, top or bottom suspended, and with a variety of grab types (clamshell, orange peel, electromagnetic, etc.).

Sie können uns gerne eine Nachricht hinterlassen. Wir werden innerhalb von 24 Stunden antworten.

Antrag einreichen